Ethylene separation method

A separation method, ethylene technology, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve problems such as excessive ethylene loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

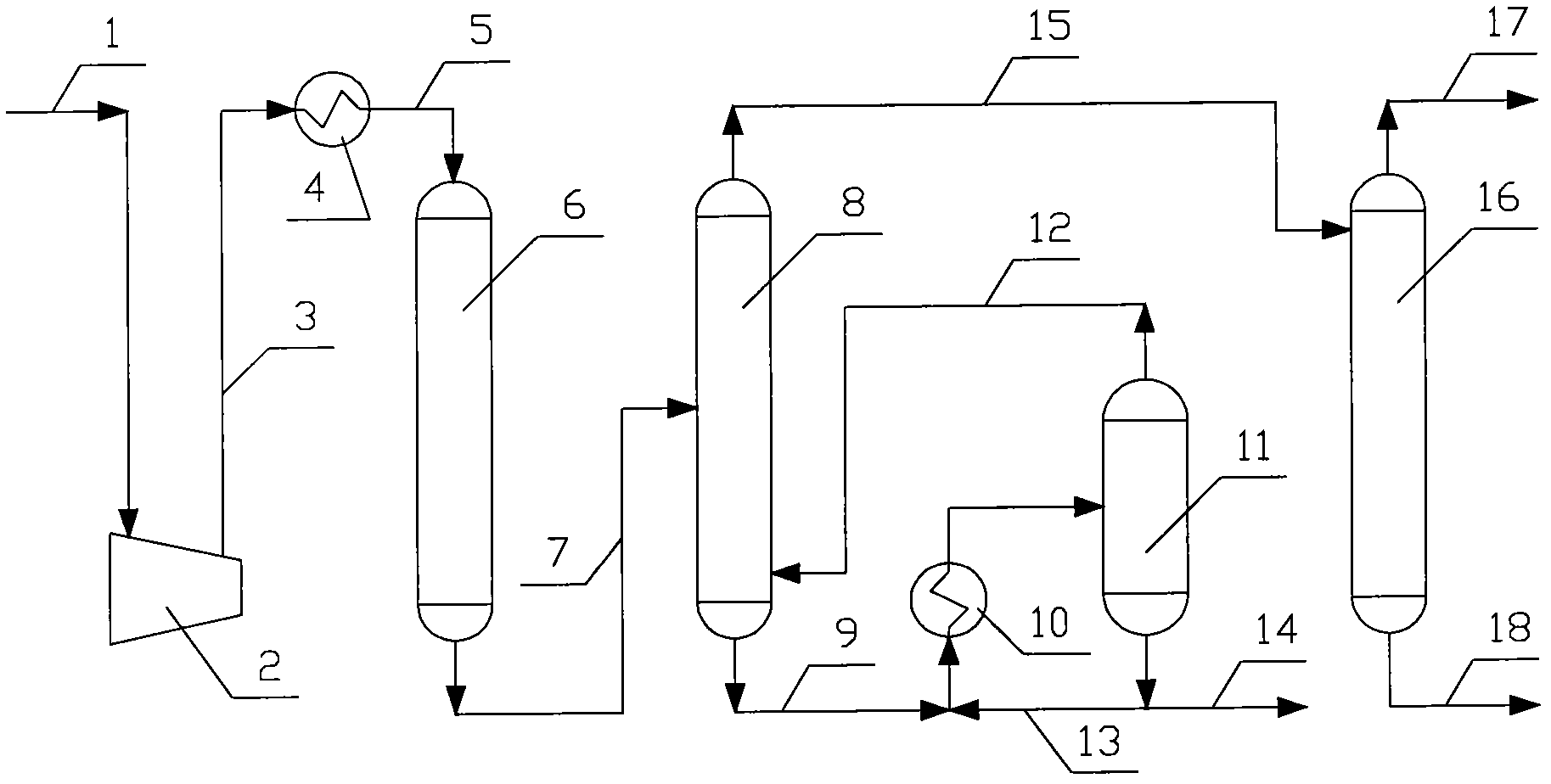

[0015] The composition of crude ethylene from the reaction system is: hydrogen 0.05kg / h, methane 2.17kg / h, carbon monoxide 3.70kg / h, ethanol 0.33kg / h, ethylene 904.92kg / h, ethane 5.07kg / h, acetaldehyde 0.34kg / h, propylene 1.12kg / h, C 3 + 4.43kg / h, ether 4.09kg / h, water 530.27kg / h. The crude ethylene stream enters the middle and lower part of the ethylene rectification tower after being compressed, cooled and dried. The ethylene rectification tower is a packed tower or a plate tower with a total of 84 theoretical trays, of which the rectification section has 48 trays. The temperature at the top of the tower is -17°C, the pressure at the bottom of the tower is 2.69MPaG, the temperature at the bottom of the tower is -2°C, the reflux ratio is 2.7, and the temperature of the reflux liquid is -20°C.

[0016] As a result, ethane, C 3 And the ethylene rectification tower still liquid of the above components, its composition is: ethanol 0.27kg / h, ethylene 27.15kg / h, ethane 17.55kg / ...

Embodiment 2

[0019] According to the conditions and steps of Example 1, the operating pressure and temperature of the ethylene rectification tower remained unchanged; the operating temperature of the flash tank was changed to 20°C, and the amount of still liquid circulating to the middle of the flash tank and the still liquid discharged to the outside were changed. The amount ratio is 120:1 (weight ratio), then the composition of the kettle liquid discharge is: ethanol 0.22kg / h, ethylene 3.27kg / h, ethane 4.01kg / h, acetaldehyde 0.27kg / h, propylene 0.89kg / h, C 3 + 3.51kg / h, ether 3.24kg / h, then the ethylene recovery rate of the ethylene rectification tower is 99.63%, and the purity of the ethylene product is 99.92%.

Embodiment 3

[0021] According to the conditions and steps of Example 1, change the top pressure of the ethylene rectification tower to 2.25MPaG, then the temperature at the top of the tower is -26°C, the pressure at the bottom of the tower is 2.29MPaG, the temperature at the bottom of the tower is -6°C, and the reflux ratio remains unchanged , the temperature of the reflux liquid is -30°C; the operating temperature of the flash tank remains unchanged, the operating pressure is changed to 2.25MPaG, and the ratio of the volume of the still liquid circulating to the middle of the flash tank to the volume of the still liquid discharged to the outside remains unchanged, then the still The composition of liquid discharge is: ethanol 0.22kg / h, ethylene 1.64kg / h, ethane 5.07kg / h, acetaldehyde 0.34kg / h, propylene 1.12kg / h, C 3 + 4.43kg / h, ether 4.09kg / h, then the ethylene recovery rate of the ethylene rectification tower is 99.82%, and the purity of the ethylene product is 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com