Cleaning device for cleaning boiler

A cleaning device and boiler cleaning technology, applied in the direction of boiler cleaning devices, etc., can solve problems such as inability to realize industrialized production, inconsistent cleaning quality, inconvenient use, etc., to achieve extended service life and effective utilization, convenient operation and control, and reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

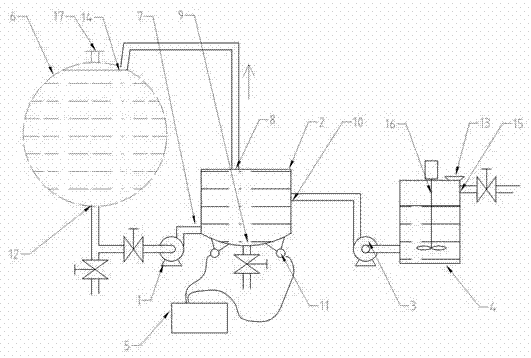

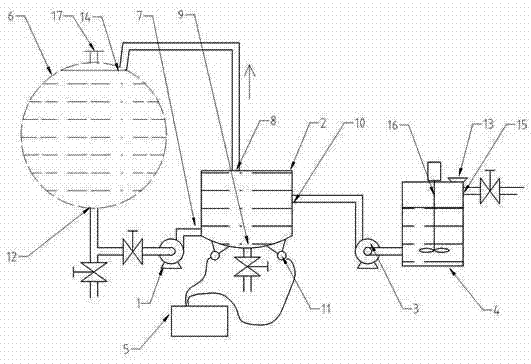

[0010] Attached below figure 1 Using a specific example, the steam boiler is used as a cleaning unit to further illustrate the structure, cleaning process and cleaning optimal formula simulation.

[0011] A cleaning device for boiler cleaning, mainly composed of a cleaning circulation pump (1), a cleaning solution treatment tank (2), a water injection pump (3) and a water supply tank (4); the cleaning circulation pump (1), the cleaning solution treatment The tank (2) and the boiler system (6) are connected through pipelines to form a cleaning liquid circulation loop; the cleaning liquid treatment tank (2) is a stainless steel sealed container, and the upper part or top of the container is provided with a liquid outlet (8), and the side of the container is provided with a back Liquid port (7) and replenishment port (10); the bottom of the container is a paraboloid, and the lowest point is a slag discharge port (9); the focal point of the paraboloid is in the center of the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com