Leakage detection device and detection method using same

A detection device and liquid level technology, applied in the field of leak detection, can solve the problems of waste liquid corrosion, high use cost, inability to distinguish the wet condition of the tank floor, etc., to monitor abnormal discharge, reduce labor load, and reduce hardware investment and the effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

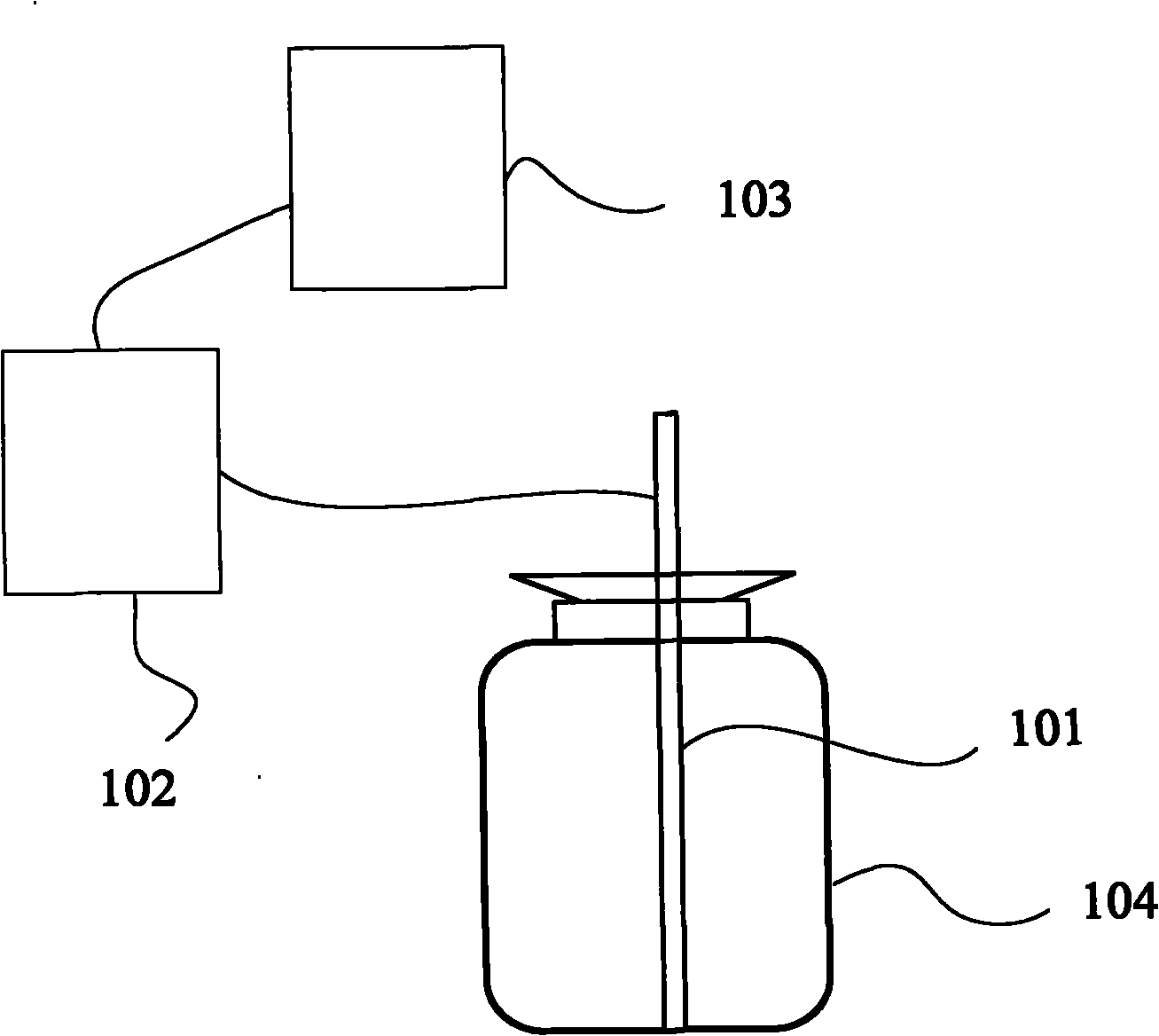

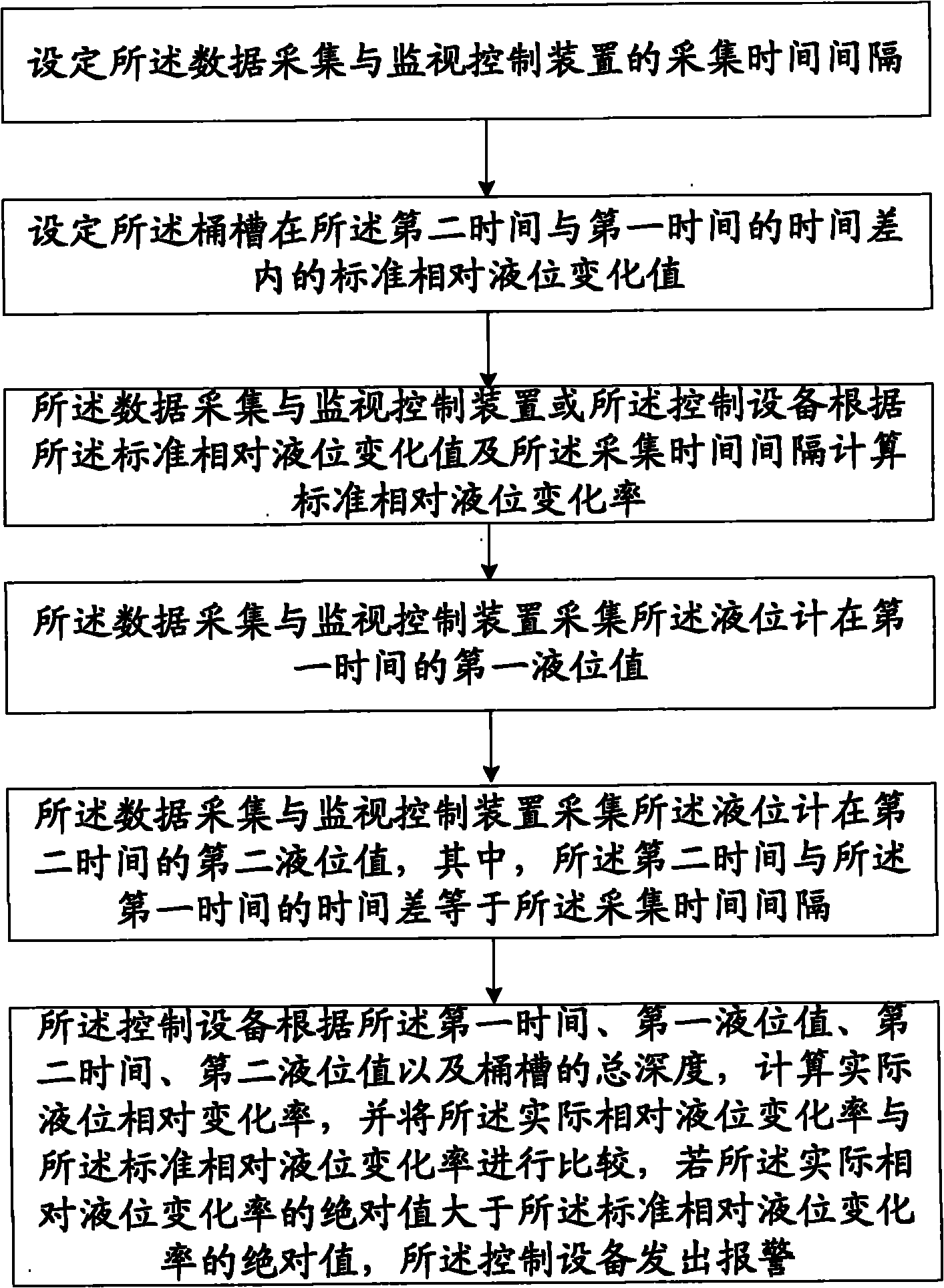

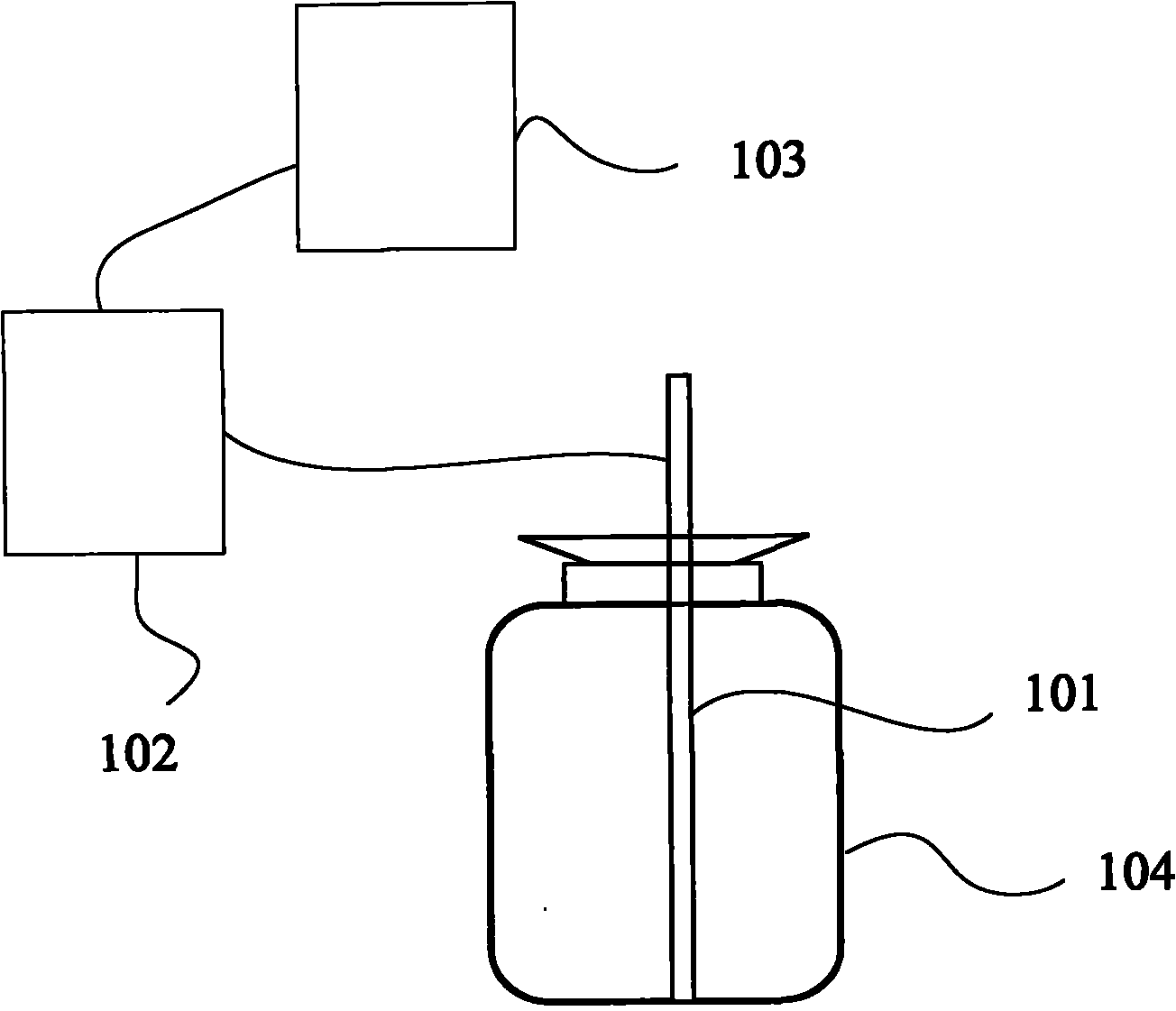

[0036] The leakage detection device and detection method proposed by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0037] The core idea of the present invention is to provide a leakage detection device, which includes a liquid level gauge, a data acquisition and monitoring control device, and a control device. Compare the absolute value of the rate of change to determine whether a large leak occurs, and then send an alarm, thereby eliminating the false alarm of the leak detector in the prior art, increasing the stability of the system, and can monitor a large number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com