Container pressure-circulation testing device and method

A cyclic test and container pressure technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems such as the inability to complete the sequential fatigue test of multiple containers, the low actual utilization efficiency of the pump, and the fatigue of the accumulator. To achieve the effect of simple operation, improved use efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

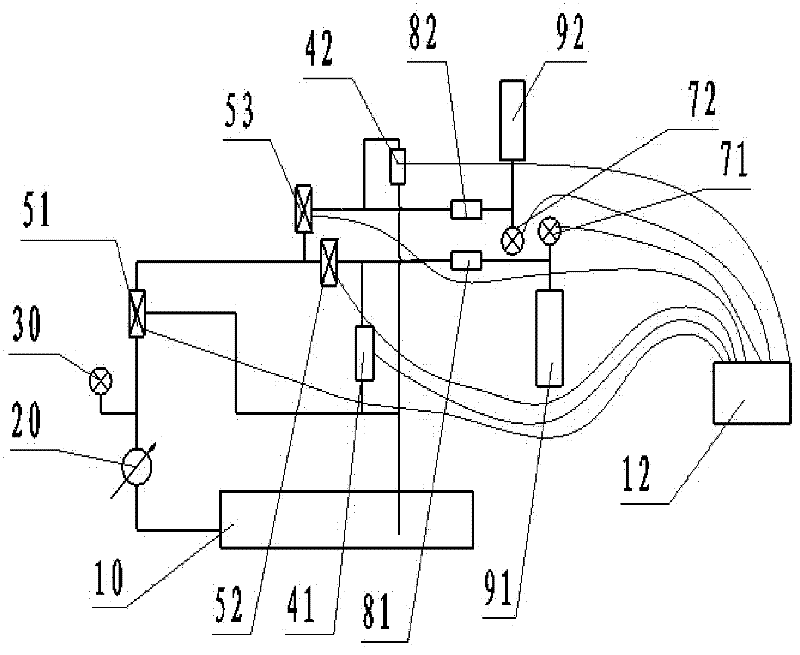

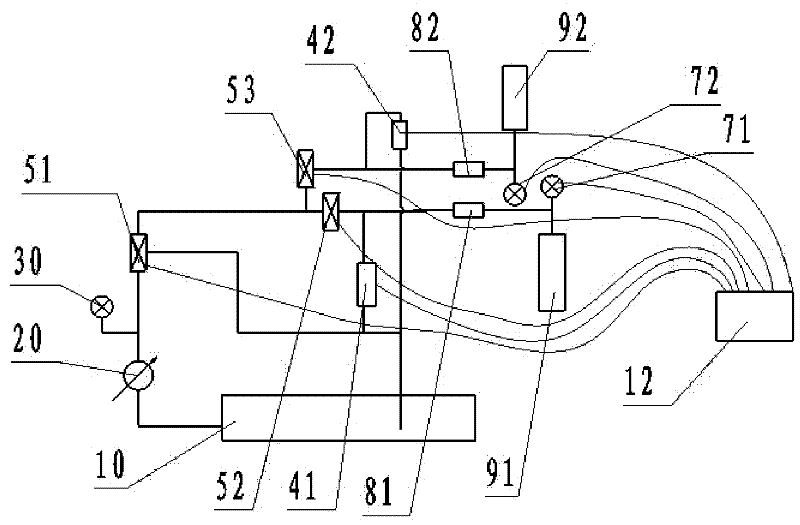

[0015] Connect the first test container (91) and the second test container (92), open the fluid pump (20), and when the fluid pump (20) is opened, the first multi-way valve (51) and the second multi-way valve (52) is opened, so that the fluid flow flows to the first test container (91) through the first pipeline system, and the pressure is passed to the control system (12) through the first pressure sensor (71), when the first test container (91) When the pressure reaches the specified pressure, the control system (12) sends an instruction to make the fluid flow to the third multi-way valve (53) through the second pipeline system. At this time, the pressure of the first test container (91) is in a pressure maintaining state The second test container (92) is in a pressurized state;

[0016] After the pressure-holding time of the first test container (91) reaches the prescribed time, the fluid in the first test container (91) flows to the first pressure relief valve (41) through...

Embodiment 2

[0021] The second test method of the container pressure cycle test device: connect the first test container (91) and the second test container (92), and turn on the fluid pump (20). The multi-way valve (51) and the second multi-way valve (52) are opened, so that the fluid flows to the first test container (91) through the first pipeline system, and the pressure signal is transmitted to the control system ( 12), when the pressure of the first test container (91) reaches the specified pressure, the second multi-way valve (52) acts to make the first test container (91) pressurized under high pressure;

[0022] While the first test container (91) is under high pressure, the fluid from the fluid pump (20) is pressurized to the second test container (92) through the second pipeline system;

[0023] After the first test container (91) high pressure holding time reaches the specified time and the pressure of the second test container (92) does not reach the specified value, the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com