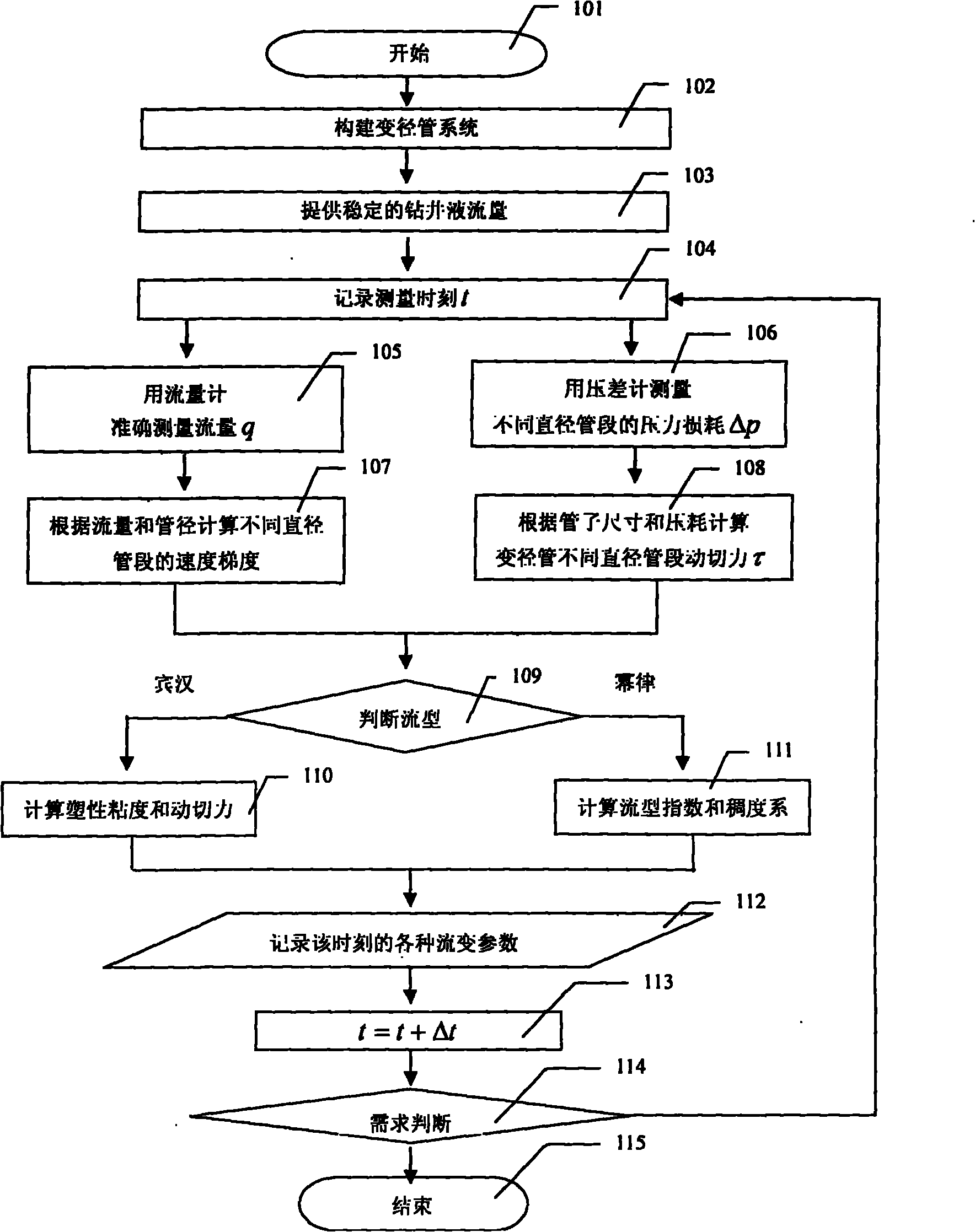

Variable-diameter-tube drilling fluid rheology measuring method

A measurement method and drilling fluid technology, applied in the direction of direct current flow characteristics measurement, etc., can solve the problems of long time, difficulty in rapid measurement of drilling fluid rheological changes, and inability to meet continuous measurement of drilling fluid rheology, etc., to improve measurement efficiency , Realize the effect of online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

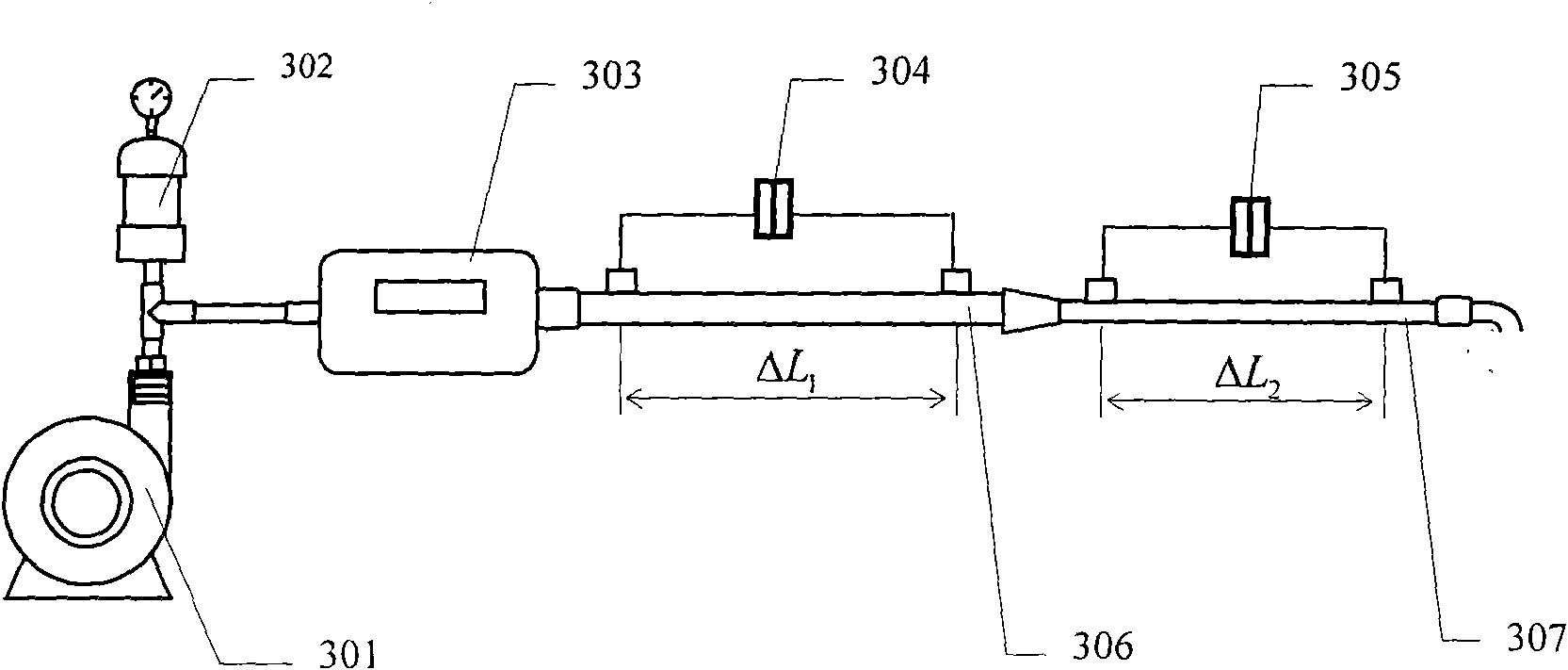

Embodiment 1

[0040] Example 1: In image 3 In the embodiment of the present invention, a constant flow pump (301) is combined with a damper (302) to provide a pulse-free flow rate, and a flow meter (303) is used to accurately measure the flow rate q of the fluid; 1 and r 2 Two capillary tubes (306 and 307) are connected in series to form a variable diameter tube to achieve different flow velocities v m (m=1, 2); according to the flow velocity v of each section of reducer m Calculate the velocity gradient γ on the wall of the two reducing pipes using the diameter of each reducing pipe 1 and gamma 2 ; Use differential pressure gauges (304 and 305) to measure the first section and the second section reducing pipe at ΔL 1 and ΔL 2 Pressure loss Δp in the tube 1 and Δp 2 , according to the radius r of the two-section reducer 1 and r 2 , length ΔL 1 and ΔL 2 , and the pressure loss Δp 1 and Δp 2 Calculation of the shear stress value τ on the pipe wall of the two sections 1 and τ ...

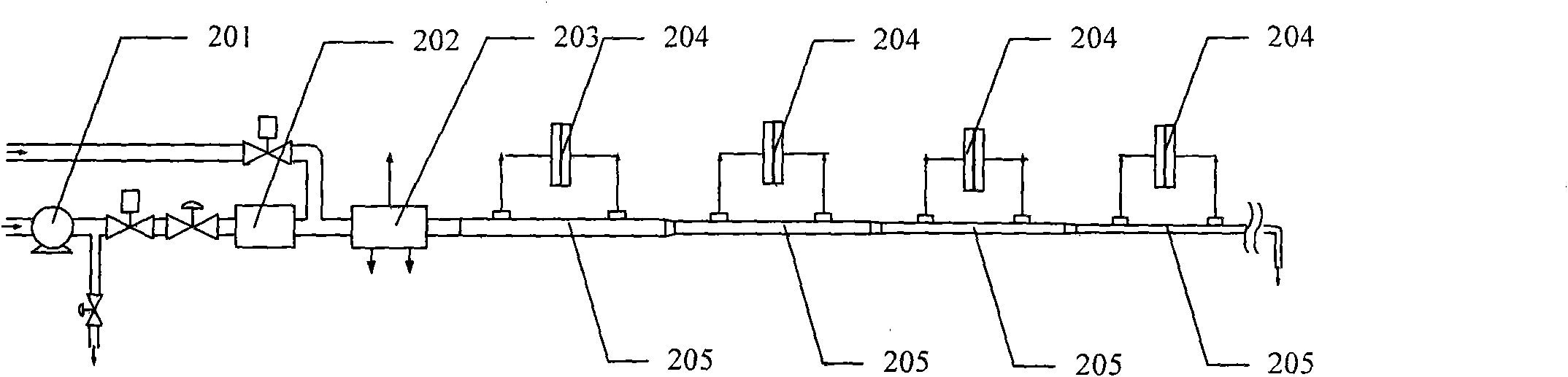

Embodiment 2

[0041] Example 2: In Figure 5 In the embodiment, a constant flow pump (501) is combined with a damper (502) to provide a pulse-free flow, and a flow meter (503) is used to accurately measure the flow q of the fluid; 1 、r 2 、r 3 、r 4 、r 5 、r 6 The six capillary tubes (516, 517, 518, 519, 520, 521) form variable diameter tubes to achieve different flow velocities v n (n=1, 2, 3, 4, 5, 6) and velocity gradient γ 1 , γ 2 , γ 3 , γ 4 , γ 5 , γ 6 ; Use pressure gauges (504 and 505) to measure the ΔL in the first capillary 1 Pressure loss Δp in the tube 1 , use pressure gauges (506 and 507) to measure the ΔL of the second capillary 2 Pressure loss Δp in the tube 2 , use pressure gauges (508 and 509) to measure ΔL in the third section capillary 3 Pressure loss Δp in the tube 3 , use pressure gauges (510 and 511) to measure the internal ΔL of the fourth section capillary 4 Pressure loss Δp in the tube 4 , use pressure gauges (512 and 513) to measure the internal ΔL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com