Inversion inductor

An integrated technology of inverter inductance, applied in the direction of transformer/inductor magnetic core, etc., can solve the problems of low production efficiency, high cost, large inductance noise, etc., and achieve the effect of simplifying assembly operation, improving production efficiency, and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

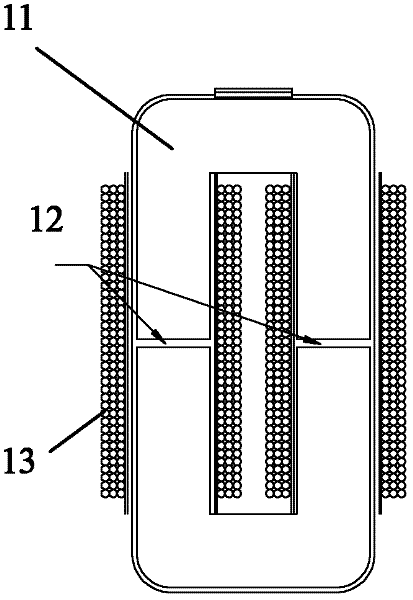

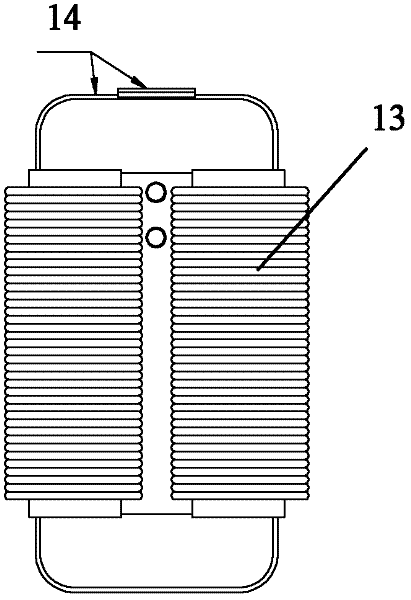

[0043] like Figure 6 to Figure 12 As shown, the inverter inductor of the present invention includes a magnetic core, a coil 25 wound on the magnetic core and a coil lead end 25 .

[0044] The magnetic core includes two plate-shaped magnetic cores 21 and two columnar magnetic cores 22, the two plate-shaped magnetic cores 21 are arranged at intervals relative to each other, and the two columnar magnetic cores 22 are vertically spaced between the two plate-shaped magnetic cores 21, The two ends of the two columnar magnetic cores 22 are docked with the opposite surfaces of the two plate-shaped magnetic cores 21 respectively, the two plate-shaped magnetic cores 21 and the two columnar magnetic cores 22 are connected as one, and the coils 25 are respectively wound on the two columnar magnetic cores. on core 22.

[0045] In this embodiment, the two plate magnetic cores 21 adopt a cuboid structure. In other embodiments, the two plate magnetic cores 21 may adopt other structural sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com