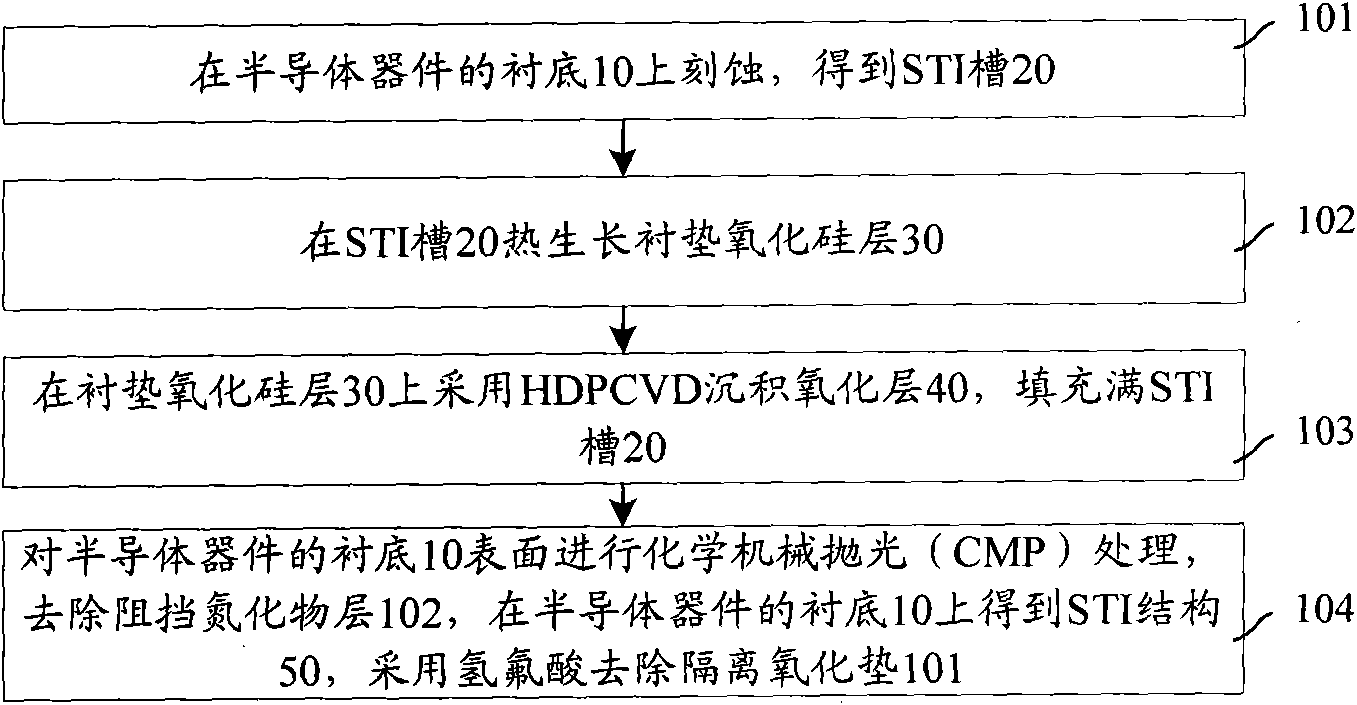

Manufacturing method of shallow trench isolation structure

A technology for shallow trench isolation and manufacturing methods, which is applied in the field of shallow trench isolation structure fabrication, and can solve problems affecting the isolation effect of semiconductor devices, semiconductor device failure, and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

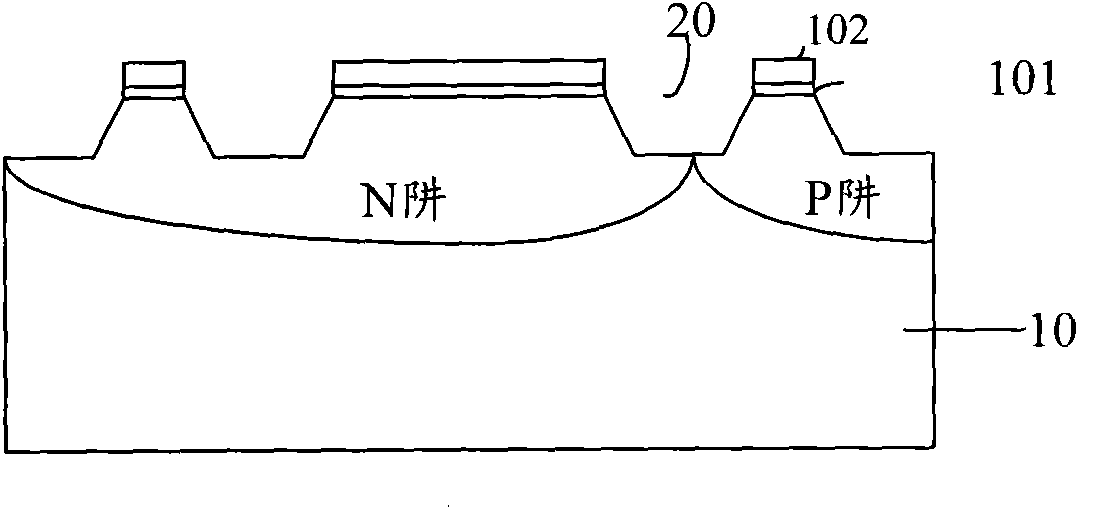

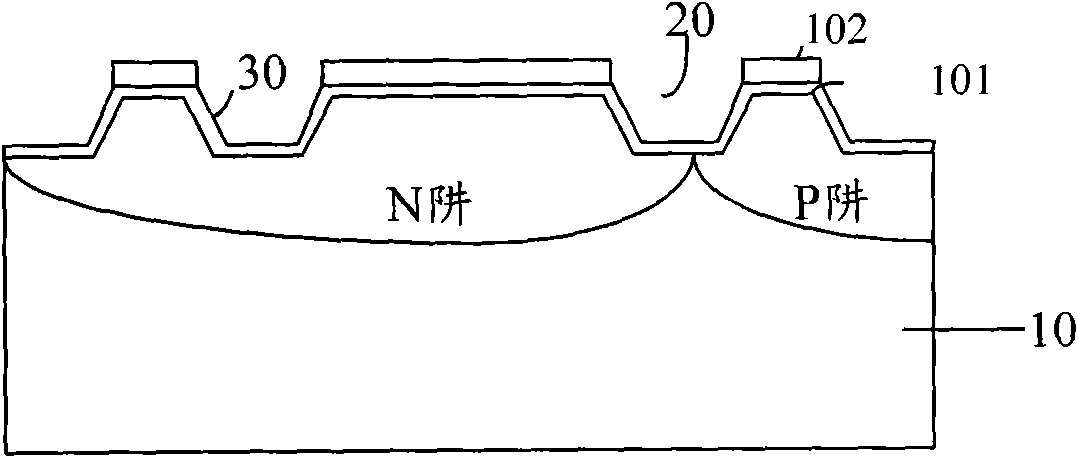

[0036] In order to ensure that the fabricated STI structure has a conforming morphology, that is, there are no gaps in the middle, the present invention does not adopt the step-back engraving of the barrier nitride layer 102 and the isolation oxide pad 101 in the prior art during the fabrication of the STI structure. Eclipse step. In order to ensure that the manufactured STI structure avoids poor defects, it cannot be filled by the gate oxide layer in the subsequent gate manufacturing process, and the material of the STI structure is changed, that is, after the formation of the STI groove, the oxygen-nitride-oxygen structure is used. Fill the STI groove, then dry etch the upper silicon dioxide layer in the oxynitride structure to the height of the STI s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com