OLED (Organic light-emitting diode) lighting substrate and manufacture method thereof

A manufacturing method and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as electrode burnout, cathode-anode short-circuit light emission, unevenness, etc., to reduce the probability of short-circuit The effect of burning out and weakening the current gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

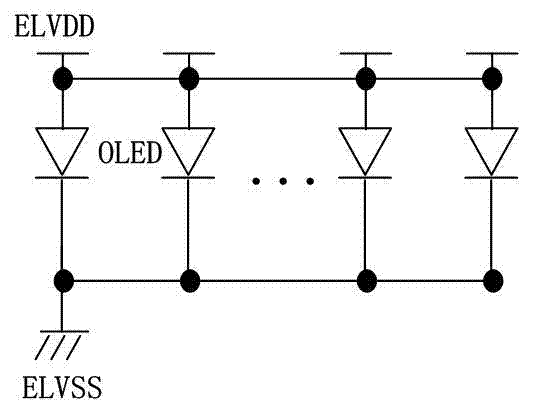

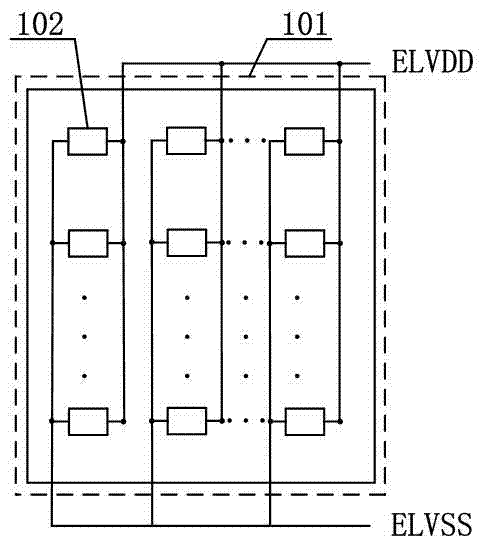

[0025] figure 2 It is a structural schematic diagram of the resistance-driven organic light-emitting display device of the present invention; image 3 It is a schematic diagram of a pixel equivalent circuit of the resistance-driven organic light-emitting display device of the present invention.

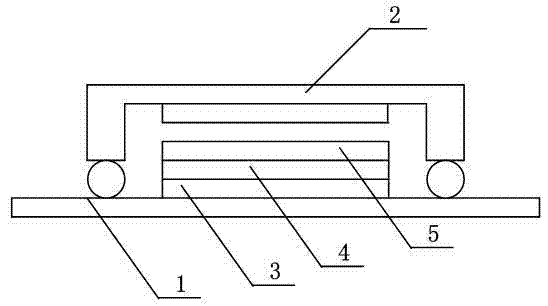

[0026] Please refer to Figure 1~ image 3 , The OLED lighting substrate of the present invention comprises a substrate 1, on which an anode 3, an organic functional layer 4 and a cathode 5 are sequentially arranged, wherein a resistance layer is arranged between the substrate 1 and the anode 3, and the resistance layer Divided into multiple block resistors, the anode 3 is divided into multiple sub-anodes, each sub-anode is connected in series with a block resistor, and the multiple block resistors are connected together through interconnecting wires.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com