Low temperature rectification cascade system for rectifying CO to produce stable isotope 13C

A stable isotope and low-temperature rectification technology, which is applied in the field of carbon stable isotope separation, can solve the problems of large pressure drop of cascade devices, difficult construction, and large energy consumption of conveying equipment, and achieve the effect of continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

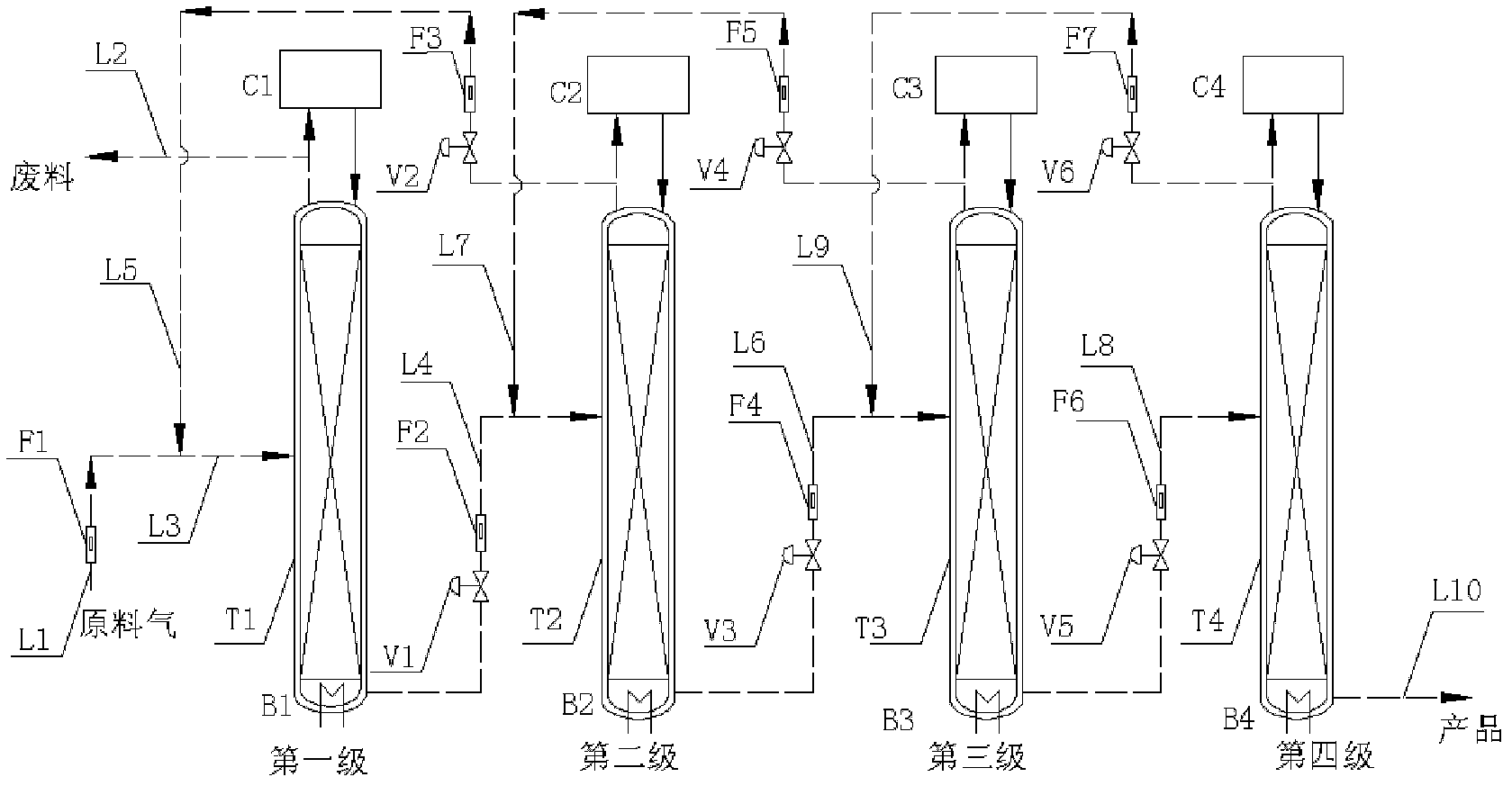

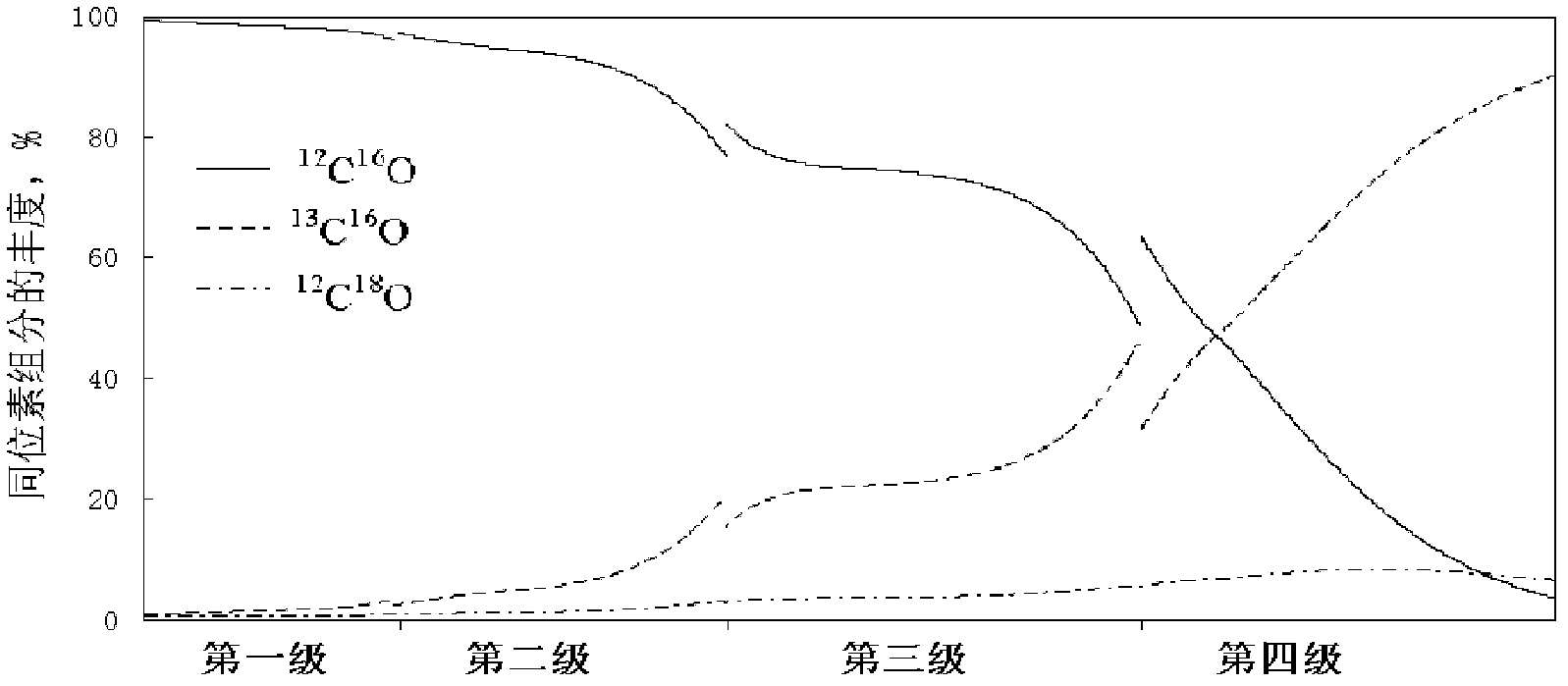

[0038] The cascade device in embodiment 1 is made up of 4 grades of rectifying towers, and the technological flow diagram of cascade device is as follows figure 2 shown. The CO raw material is measured by the flow meter F1 and then transported to the middle of the first stage tower T1 by the pipeline L3. The T1 tower is filled with corrugated wire mesh packing, which is the liquid condensed and refluxed in the top condenser C1 and the bottom reboiler B1. The vaporized vapor provides a surface for heat and mass transfer. The high-abundance carbon-12 is taken out from the top of the T1 tower through the pipeline L2, and a part of the steam is taken out from the bottom of the T1 tower. Driven by the pressure, it is measured through the valve V1 and the flow meter F2 and then sent to the middle of the tower T2 along the pipeline L4. The T2 tower It is filled with wire mesh corrugated packing to provide heat and mass transfer surfaces for the liquid condensed and refluxed in the ...

Embodiment 2

[0044] The cascade device in embodiment 2 is made up of 4 grades of rectifying towers, and the technological flow diagram of cascade device is as follows Figure 4 shown. The CO raw material is measured by the flow meter F1 and then transported to the middle of the first stage tower T1 by the pipeline L3. The T1 tower is filled with corrugated wire mesh packing, which is the liquid condensed and refluxed in the top condenser C1 and the bottom reboiler B1. The vaporized vapor provides a surface for heat and mass transfer. The high-abundance carbon-12 is taken out from the top of the T1 tower through the pipeline L2, and a part of the steam is taken out from the bottom of the T1 tower, and is transported to the middle of the tower T2 ( Figure 4 Midpoint d position), the T2 tower is filled with corrugated wire mesh packing, which provides a surface for heat transfer and mass transfer for the liquid condensed and refluxed in the top condenser C2 and the evaporated vapor in the b...

Embodiment 3

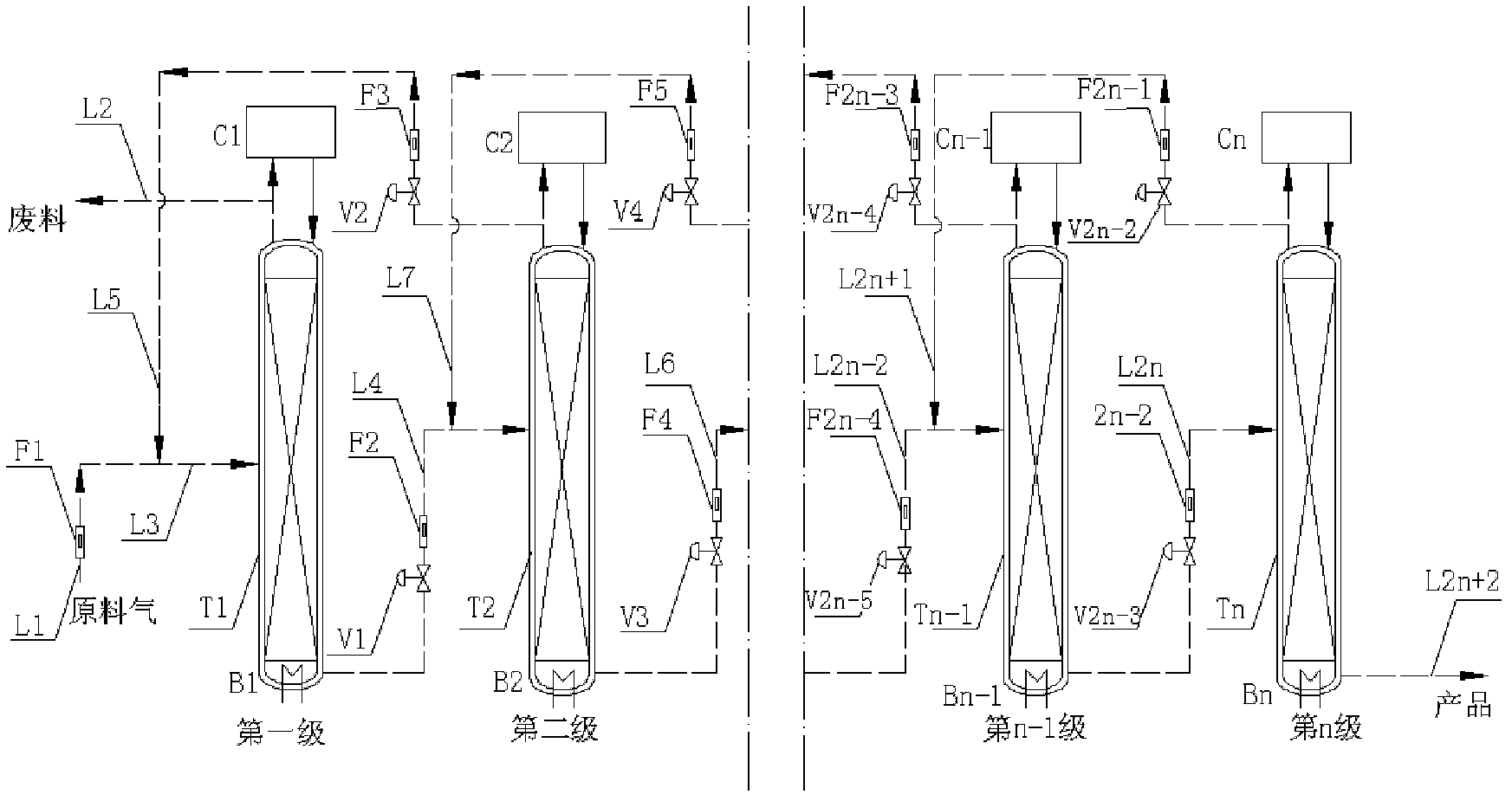

[0050] A rectification of CO to produce stable isotopes 13 The low-temperature rectification cascade system of C is a cascade device composed of horizontally placed two-stage rectification towers with gradually tapered diameters. The rectification tower is composed of a top condenser, a bottom reboiler and a rectification column. The distillation towers are connected by pipelines. The first-stage rectification tower inputs raw materials from the middle, and the steam at the top of the rear-stage rectification tower is transported to the middle of the front-stage rectification tower by pressure through pipelines, and the liquid produced in the bottom of the front-stage rectification tower is vaporized in the pipeline. Under the action of pressure, it is transported to the middle of the rear stage rectification tower, and the steam at the top of the latter stage rectification tower can enter the front stage rectification tower at the feed point of the front stage rectification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com