Large-temperature-difference concentrated energy station refrigerating system

A technology of refrigeration system and energy station, applied in air-conditioning system, water shower cooler, household heating and other directions, can solve the problems of large conveying flow and waste of conveying power consumption, etc., to improve conveying efficiency, reduce conveying energy consumption, improve Effect of return water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

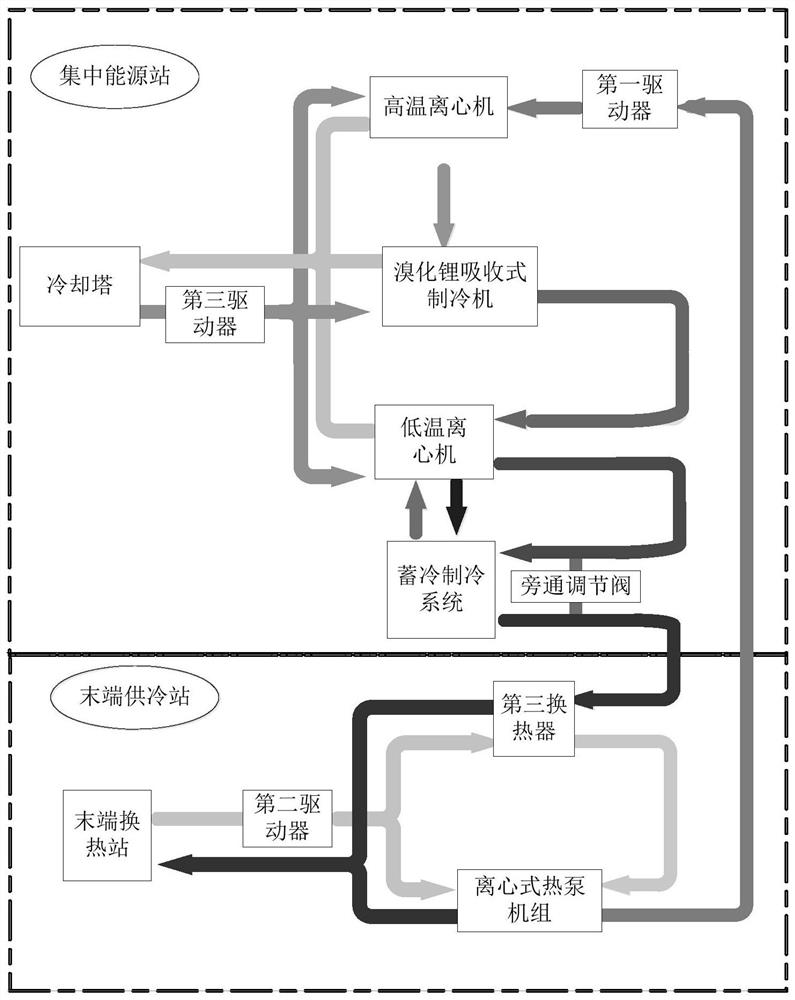

[0028] figure 1 It is a connection block diagram of a structure of the large temperature difference centralized energy station refrigeration system in the present invention, such as figure 1 As shown, this embodiment discloses a large temperature difference centralized energy station refrigeration system, including:

[0029] A centralized energy station, which is used to provide cooling water for the terminal cooling station;

[0030] The terminal cooling station is used to exchange heat with the terminal heat exchange station through cooling water, and is also used to provide the return water after heat exchange to the centralized energy station; the terminal cooling station is also equipped with a centrifugal heat pump unit, the The centrifugal heat pump unit is used to increase the temperature of the return water, so that the temperature difference between it and the cooling water is not less than 20°C;

[0031] A circulating delivery pipeline, which is arranged between t...

Embodiment 2

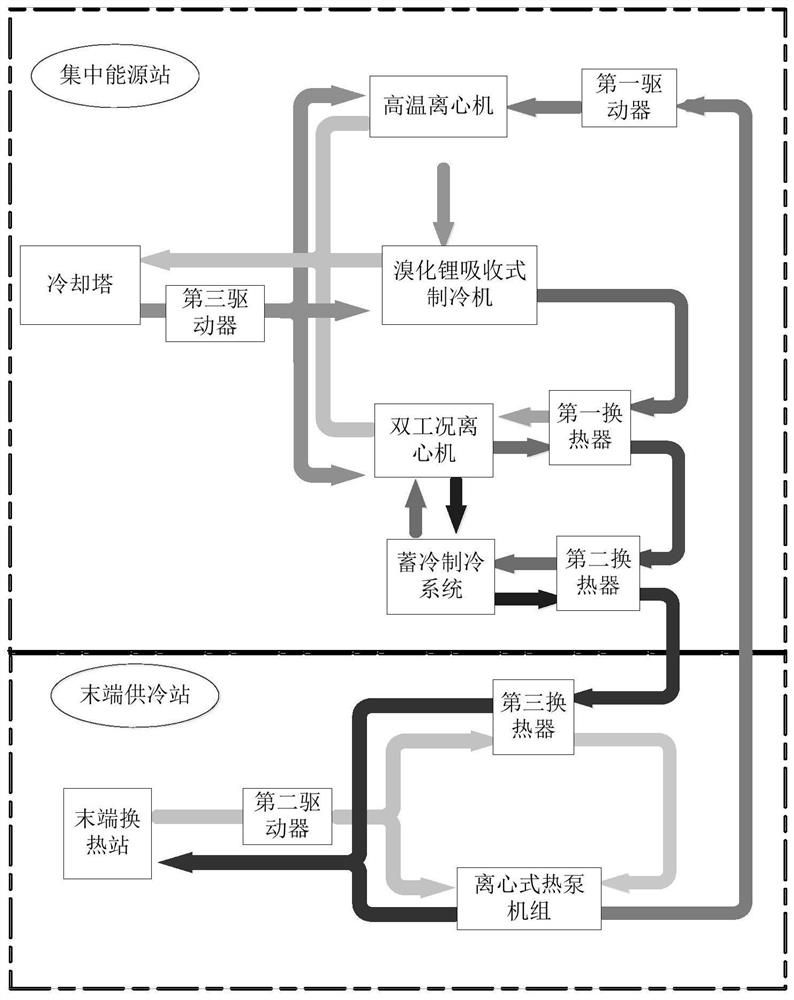

[0042] figure 2 It is a connection block diagram of another structure of the refrigeration system of the central energy station with large temperature difference in the present invention, such as figure 2 As shown, most of the structure of this embodiment is the same as that of Embodiment 1, the difference is that the low-temperature centrifuge in the refrigeration mechanism is replaced by a double-working condition centrifugal unit, and a second communication circuit is provided between the cold storage refrigeration system, and the Used to make ice for cold storage refrigeration system. Specifically, the refrigeration mechanism includes a high-temperature centrifuge, a lithium bromide absorption refrigerator, a dual-working condition centrifugal unit, and a cold storage refrigeration system. The systems are all equipped with cooling passages, and the cooling passages are connected in sequence; the cold storage refrigeration system is provided with an ice storage tank, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com