Primary brine calcium and magnesium ion content control and monitoring system and control method thereof

A technology of calcium and magnesium ions and magnesium ions, which is applied to a calcium and magnesium ion content control and monitoring system in primary brine and its control field, can solve problems such as changes in the content of calcium and magnesium ions in raw materials, insufficient addition of refined preparations, and influences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

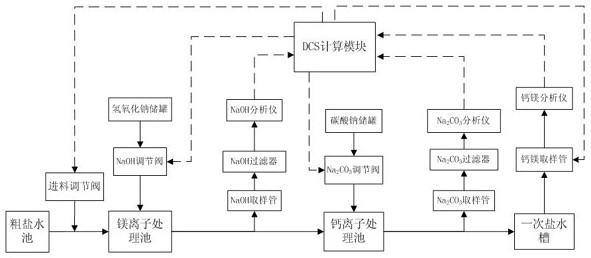

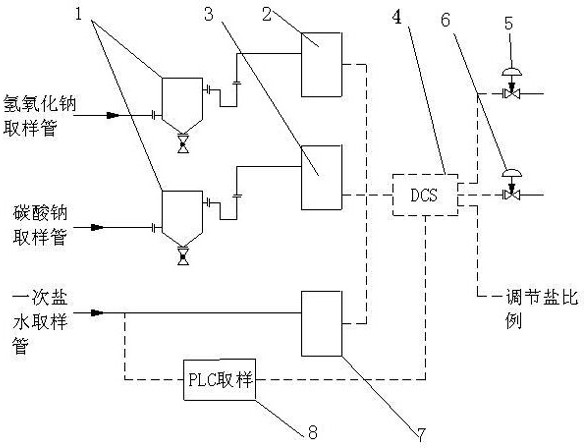

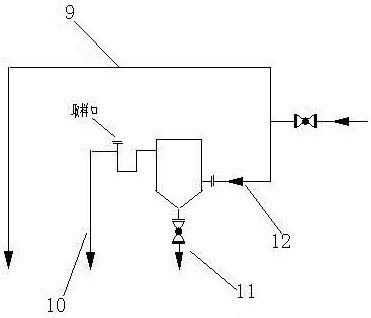

[0022] see figure 1 with figure 2 , the primary brine calcium and magnesium ion content control and monitoring system used in the operation method of the present invention consists of a magnesium ion treatment tank, a sodium hydroxide storage tank, a sodium carbonate storage tank, a filter 1, a regulating valve, a calcium ion treatment tank, and a calcium and magnesium analyzer 7. It is composed of a salt water tank and DCS calculation module 4, etc. The crude brine is transported from the crude brine tank to the magnesium ion treatment tank, and a feed regulating valve is set on the delivery pipeline. The sodium hydroxide storage tank is connected with the magnesium ion treatment tank through a pipeline, and a sodium hydroxide regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com