Hand layup molding process of polymer matrix composite

A technology of composite materials and hand lay-up molding, which is applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of long production cycle, low production efficiency, high product scrap rate, etc., and achieve saving resin consumption and high production efficiency , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following takes the forming of a slope plate as an example and further elaborates in conjunction with specific diagrams.

[0019] The hand lay-up of slope boards includes three processes: material preparation, product production, and post-curing. The specific process of each process is as follows:

[0020] Material preparation process: cutting fiber cloth for reinforcement into required specifications, cutting and processing foam into required specifications, blending resin, mold preparation, machine preheating, etc. When preparing the resin, an appropriate amount of curing agent and accelerator should be added according to the type of resin, room temperature, and reserved operating time. It is best to choose a resin with a higher Tg temperature (glass transition temperature).

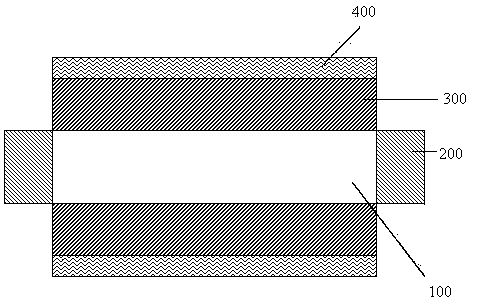

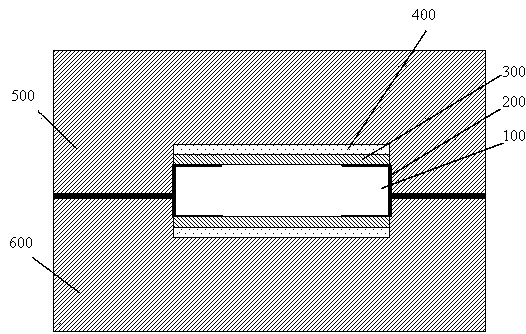

[0021] Product manufacturing process: such as figure 1 As shown, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com