Haulage winch with electromagnetic speed-regulating motor

An electromagnetic speed regulation and winch technology, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of unfavorable automatic control, inconvenient operation and maintenance, high manufacturing cost, improve labor productivity and safety, and facilitate medium and remote control. , the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

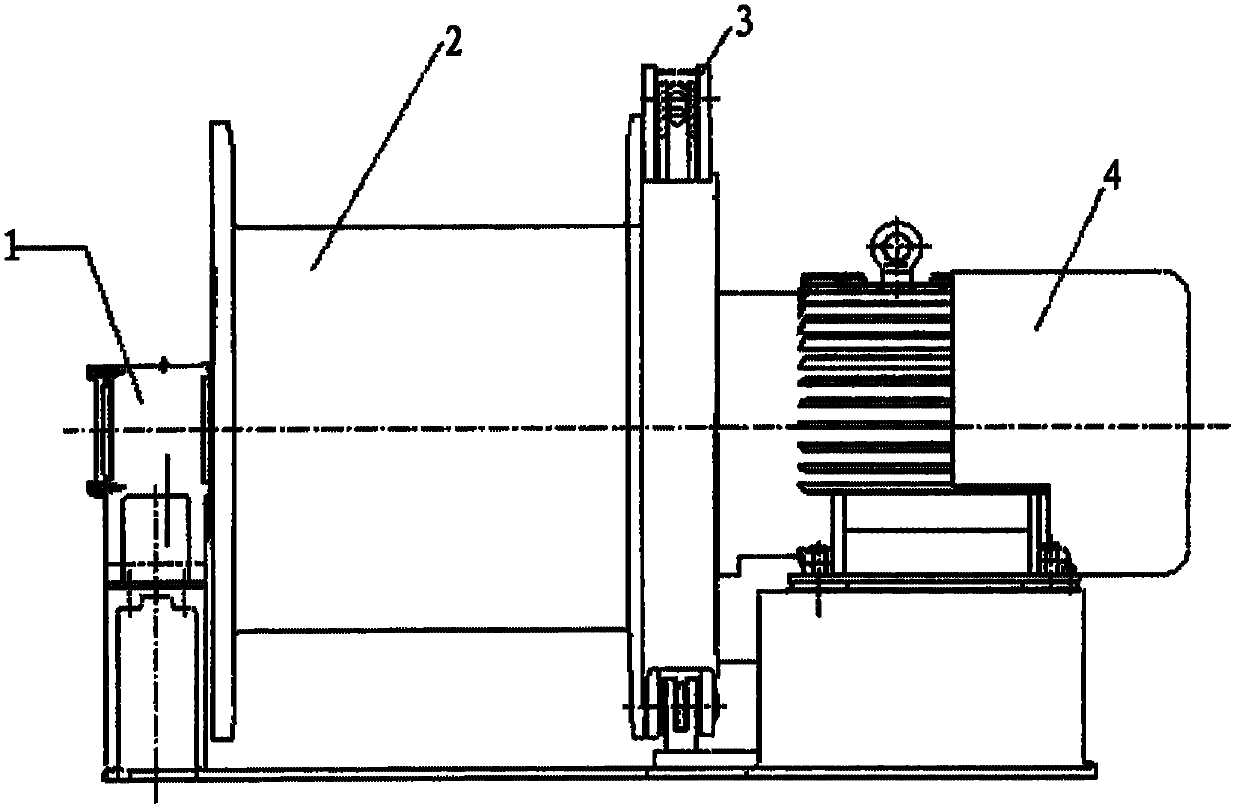

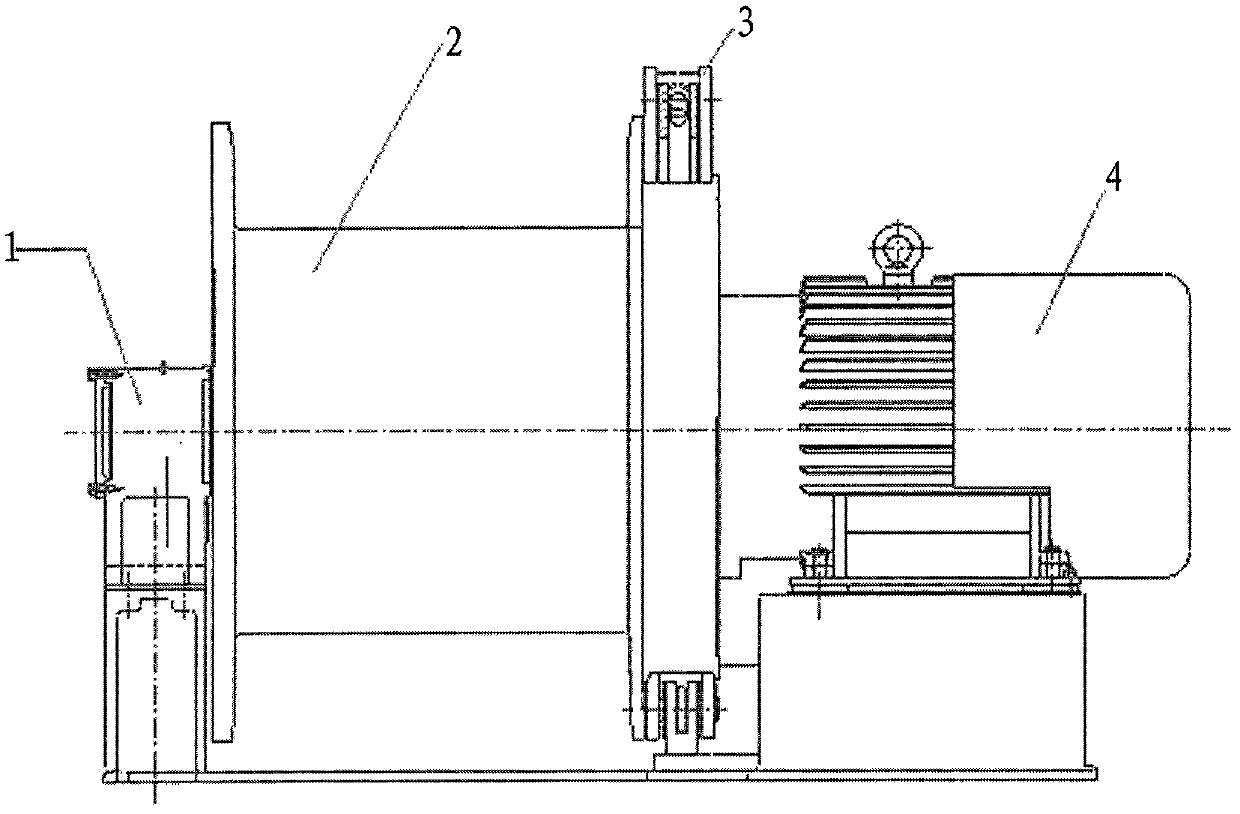

[0009] like figure 1 As shown, a transport winch using an electromagnetic speed-regulating motor is mainly composed of a bearing seat 1, a reel 2, a safety brake 3, and an electromagnetic speed-regulating motor 4. The right end of the reel 2 is connected to a safety brake 3, and the left end of the reel 2 A bearing seat 1 is connected, and an electromagnetic speed-regulating motor 4 is connected to the right end of its safety brake 3 .

[0010] The existing transport winch adopts a 2-stage planetary gear transmission structure and is equipped with 2 sets of braking devices. The operator manually adjusts the reel speed to achieve different speeds in pulling heavy objects and rewinding. After adopting the electromagnetic speed regulating motor, while replacing the two-stage planetary gear transmission, one set of braking device is reduced, and only one set of braking device is reserved on the reel for safety braking. The speed regulation of the reel is realized by a special spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com