Semi-dry process air humidifying and dehumidifying type seawater desalinating system and method

A semi-dry, gas technology, used in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of heat waste carried by concentrated brine, easily damaged nozzles, heat waste, etc., and achieve high efficiency in the exothermic condensation process. , the effect of increasing the residence time and increasing the convective heat transfer coefficient outside the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

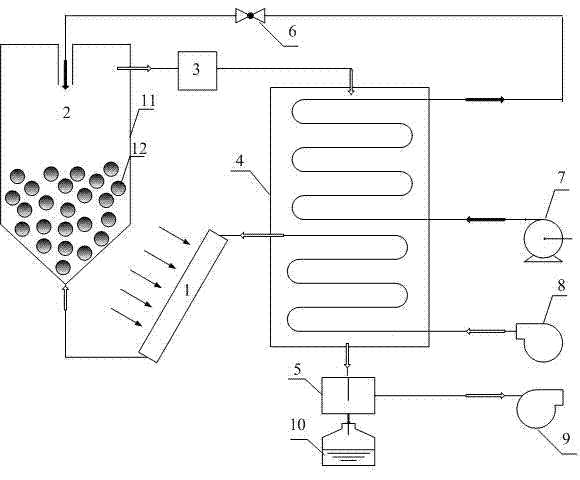

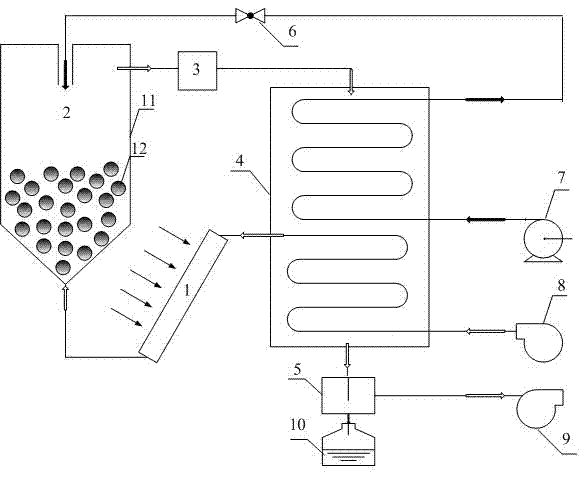

[0014] The semi-dry gas humidification and dehumidification type seawater desalination system proposed by the present invention, such as figure 1 shown. This embodiment includes: solar air heat collector 1, spouted bed evaporator 2, bag filter 3, horizontal tube falling film condenser 4 and steam-water separator 5, wherein: the output end of solar air heat collector 1 is connected to the spray The nozzle at the bottom of the spouted bed evaporator 2 is connected, the seawater input source is connected with the seawater inlet pipe at the top of the spouted bed evaporator 2, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com