Anaerobic reaction furnace for producing combustible gas

An anaerobic reaction and gas technology, applied in the field of anaerobic reactors, can solve the problems of high price, large air pollution, large floor space, etc., and achieve the effect of solving processing problems and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

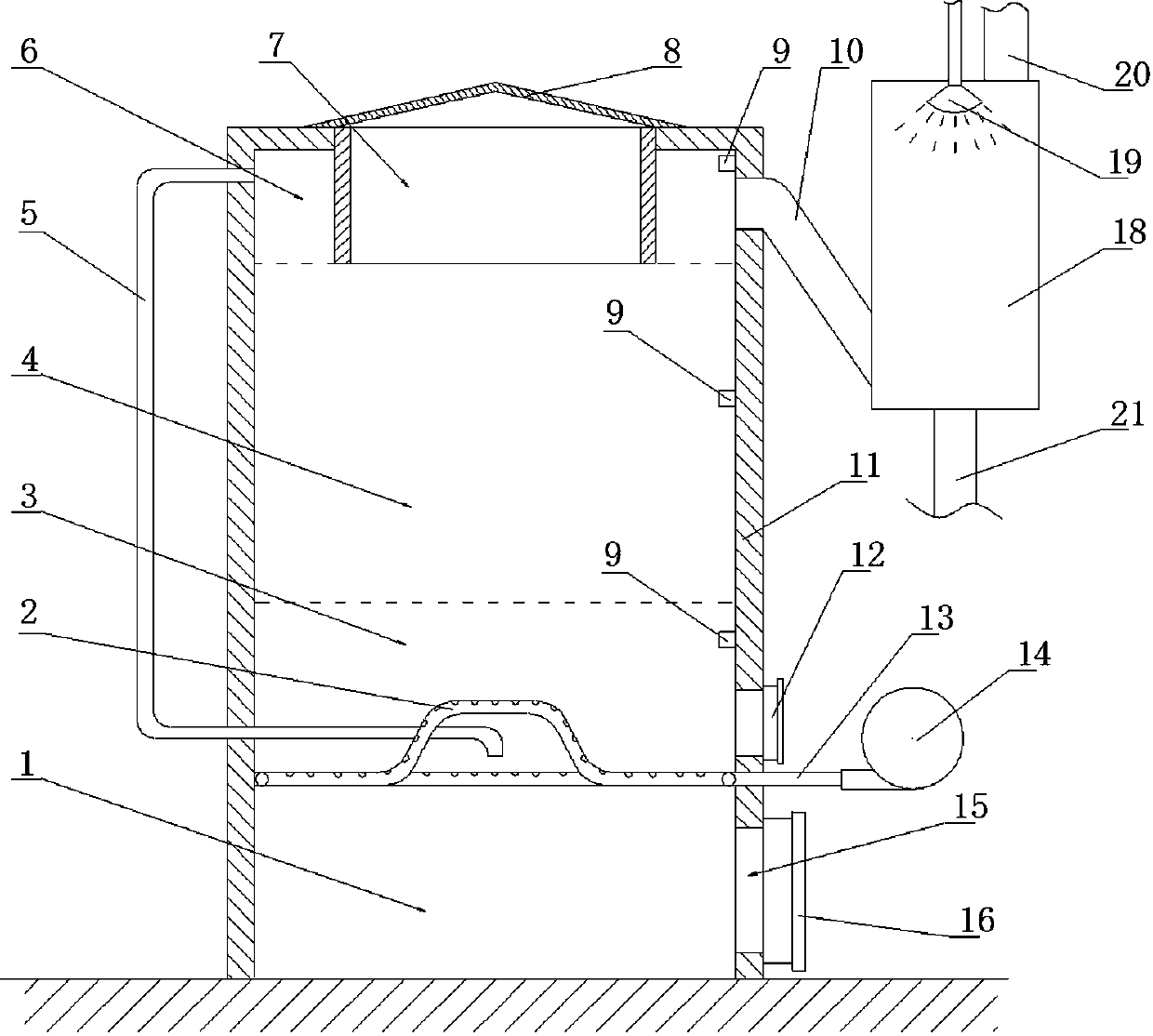

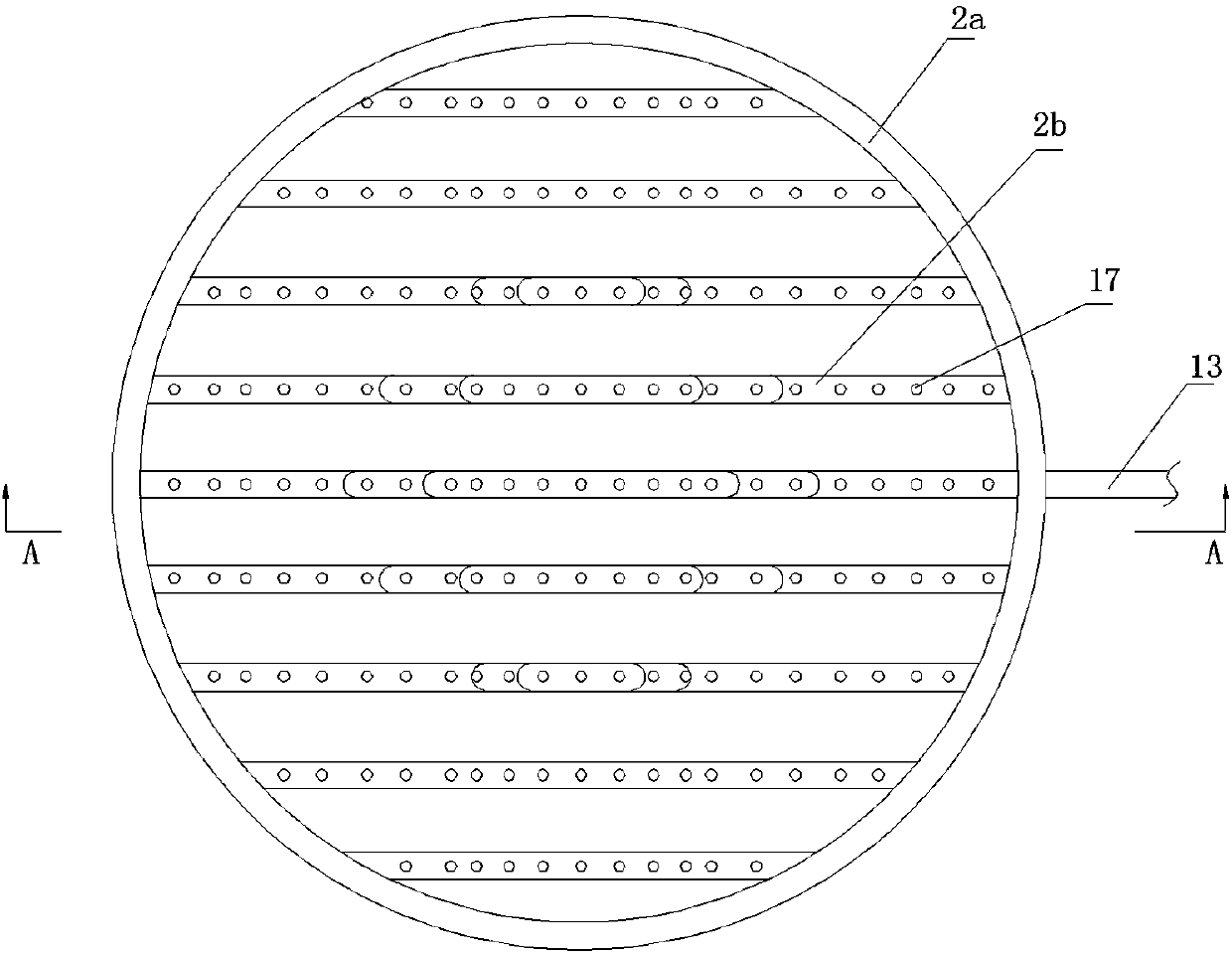

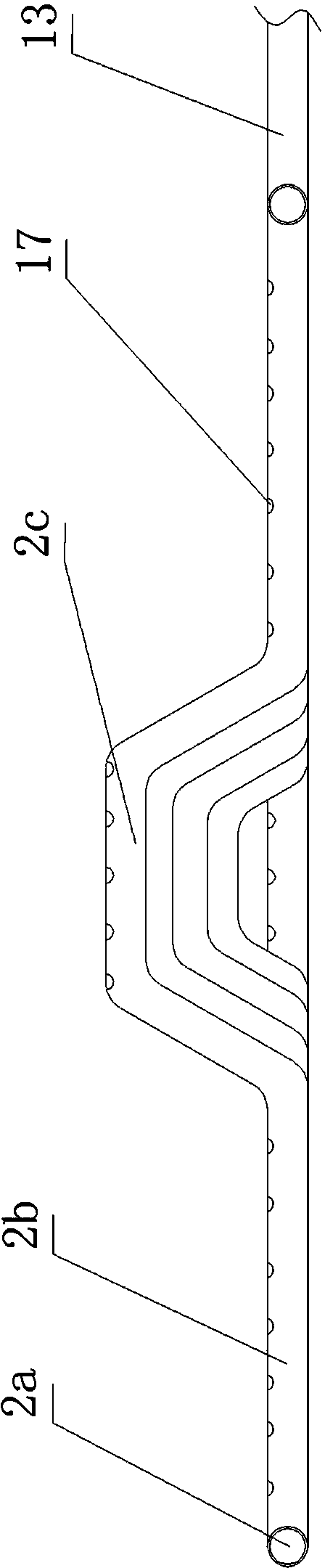

[0025] see Figures 1 to 2, an anaerobic reaction furnace for generating combustible gas, comprising a vertical furnace body 11, the interior of the furnace body 11 is divided into an upper chamber and a lower chamber by a furnace bridge 2, the upper part of the furnace bridge 2 is a reaction chamber, and the reaction chamber is from the upper Downwards include gas gathering chamber 6, drying zone 4, and anaerobic combustion reaction zone 3. 15 to 25% of the height of the reaction chamber is gas gathering chamber 6, and 20% of the height is the best. The volume of gas gathering chamber 6 The minimum, 45-55% of the height of the reaction chamber is the drying zone 4, and 50% is the best, the volume of the drying zone 4 is the largest, and 30% of the height of the reaction chamber is the anaerobic combustion reaction zone 3. Zone 3 is adjacent to the furnace bridge 2; below the furnace bridge 2 is the ash deposit chamber 1, the ash deposit chamber 1 is provided with a slag outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com