Integrated thin-film photovoltaic device and manufacturing method thereof

A technology for optoelectronic components and manufacturing methods, which is applied in the fields of electrical components, photovoltaic power generation, and final product manufacturing, and can solve problems such as shortage of raw materials and rising prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

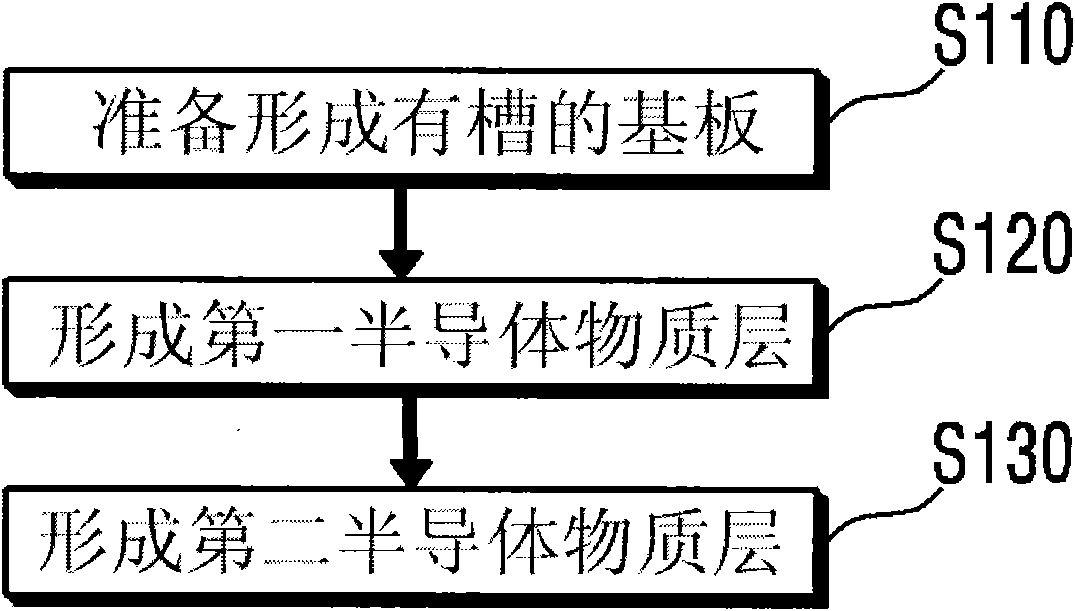

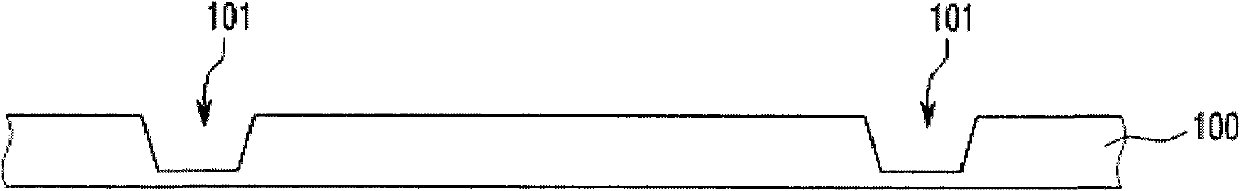

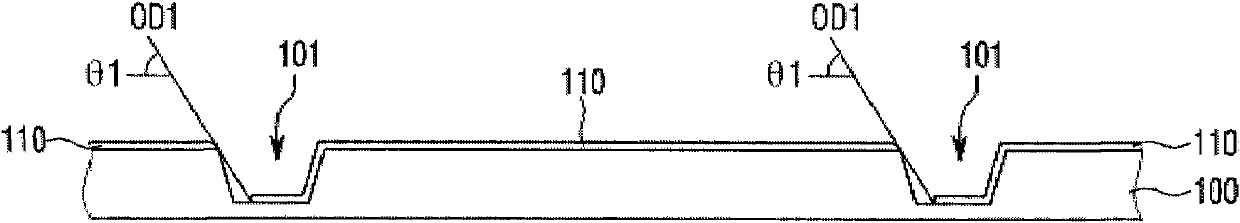

[0045] Figure 2a ~ Figure 2g A method of manufacturing an integrated thin film photovoltaic element according to a first embodiment of the present invention is shown.

[0046] Such as Figure 2aAs shown, a substrate 100 formed with grooves 101 is prepared. The substrate 100 is preferably made of a transparent insulating material or an opaque insulating material or a transparent conductive material or an opaque conductive material with excellent light transmittance. For example, when a transparent insulating material is used, the substrate 100 may be one of a glass substrate such as soda lime glass or tempered glass, a transparent plastic substrate, or a nanocomposite substrate. A nanocomposite material is a material in which nanocrystalline grains are dispersed in a disperse medium (matrix, continuous phase) in the form of a disperse phase. The dispersion medium can be organic solvents, plastics, metals or ceramics, and the nanocrystalline grains can be plastics, metals or...

no. 2 example

[0081] Figure 3a ~ Figure 3f A method of manufacturing a see-through type integrated thin film photovoltaic element according to an embodiment of the present invention is shown.

[0082] Such as Figure 3a As shown, a substrate 200 in which grooves 201, 203, 205 and holes 202, 204 are formed is prepared.

[0083] The holes 202 , 204 are located between adjacent grooves 201 , 203 , 205 . A series connection is formed between adjacent unit cells in the grooves 201, 203, 205, and the holes 202, 204 are for light transmission. The grooves 201 , 203 , 205 and the holes 202 , 204 can be formed by the same method, and the method of forming the grooves 201 , 203 , 205 and the holes 202 , 204 has been described in the first embodiment, so it is omitted. At this time, the grooves 201, 203, 205 and the holes 202, 204 may be formed simultaneously.

[0084] The ratio of depth d1 to width w1 or diameter w1 of holes 202 , 204 may be greater than the ratio of depth d2 to width w2 of groo...

no. 3 example

[0095] Figure 4a ~ Figure 4e A method of manufacturing an integrated thin film photovoltaic element according to a third embodiment of the present invention is shown.

[0096] Such as Figure 4a As shown, a substrate 300 is prepared in which grooves 301 are formed such that both side surfaces are inclined at an angle α in the same direction at regular intervals.

[0097] Such as Figure 4b As shown, the first pure silicon is discharged in the direction perpendicular to the substrate in the first impurity atmosphere or together with the first impurity or the first extrinsic silicon substance is discharged in the vertical direction to the substrate, and the first extrinsic silicon is discharged in the groove A part of the bottom surface and a side surface of 301 are crystallized during or after deposition on the region between adjacent grooves 301 . Thus, the first extrinsic polysilicon layer 310 is formed. In the third embodiment, since the groove 301 is inclined, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com