Permanent magnet synchronous motor for extended range electric automobile

A permanent magnet synchronous motor, electric vehicle technology, applied in electric vehicles, motors, electric components and other directions, can solve the problems of increasing the cost of the whole vehicle, complex assembly process, occupying a lot of space, etc., and achieves low cost, small size and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

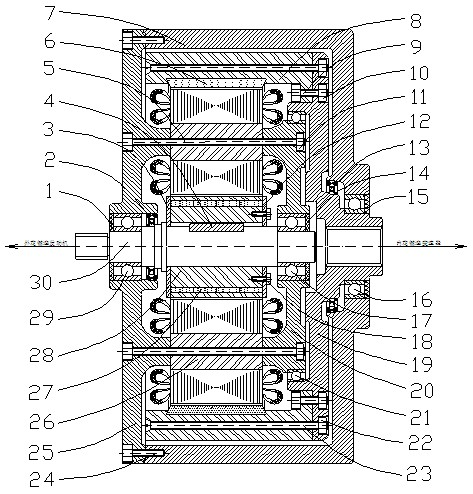

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] see figure 1 A permanent magnet synchronous motor for an extended-range electric vehicle shown includes a housing 7 and an end cover 25 connected to one end of the housing; a stator, an inner rotor and an outer rotor are arranged in the housing, and the inner rotor is located at In the inner cavity of the stator, the outer rotor is sleeved on the outside of the stator to form an inner rotor motor and an outer rotor motor; the inner rotor motor and the outer rotor motor share a stator, both of which are radial flux motors. The inner rotor motor is a range-extending generator, which is connected to the engine; the outer rotor motor is a pure electric drive motor, which is connected to the transmission; when and how the inner rotor motor and the outer rotor motor operate depend on the motor controllers that control them respectively.

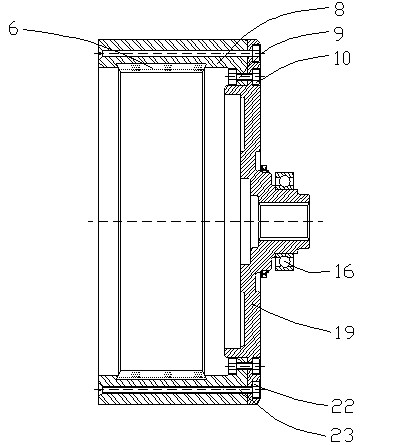

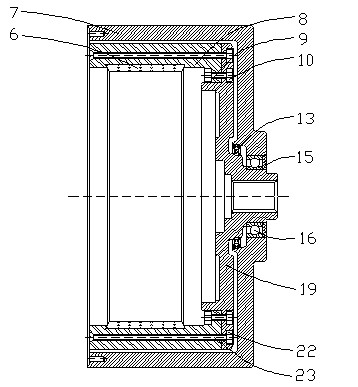

[0021] see figure 2 The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com