Zinc-based black rust inhibitor, rust inhibiting coating film, and rust inhibiting metal member

A kind of anti-rust agent, black technology, applied in the direction of metal layered products, anti-corrosion coatings, coatings, etc., can solve the problems of poor concealment rate, inability to maintain black for a long time, red change, etc., and achieve the effect of excellent anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] The present invention will be described in detail through embodiments below, but the present invention is not limited to these examples.

[0087] Prepare the following metal substrate samples 1 and 2 as metal substrates:

[0088] (1) Metal substrate sample 1: SPCC, 5D steel plate, size: 70×150×0.8mm

[0089] (2) Metal substrate sample 2: Bolt (mild steel), M10×55, pitch 1.5mm, hardness 9T

Embodiment approach 1

[0091] After the metal substrate samples 1 and 2 were degreased by a solvent, the surface was ground by shot blasting to complete the pretreatment of each sample.

[0092] Mix in 34.6 parts by mass of deionized water (8.00 μS / cm or less), add 13.5 parts by mass of γ-glycidyl trimethoxysilane (manufactured by CHISSO Corporation: S510) as (4) silane coupling agent, and mix together . After mixing the above components for 3 hours, 0.8 parts by mass of orthoboric acid (manufactured by Wako Pure Chemical Industries, Ltd.), and 1.0 parts by mass of nonionic surfactant (HLB9.5) (NOF Corporation: NONION) were added to the mixture. NS-204.5), 1.0 parts by mass of nonionic surfactant (HLB13.5) (NOF Corporation: NONION NS-208.5), and an appropriate amount of other additives such as antifoaming agent Subtotal 7.9 mass parts, mix together. Now, 11.4 parts by mass of dipropylene glycol (manufactured by ASAHI GLASS CO., LTD., abbreviated as "DPG") was added to this mixture as (5) Alcohol-b...

Embodiment approach 2~9

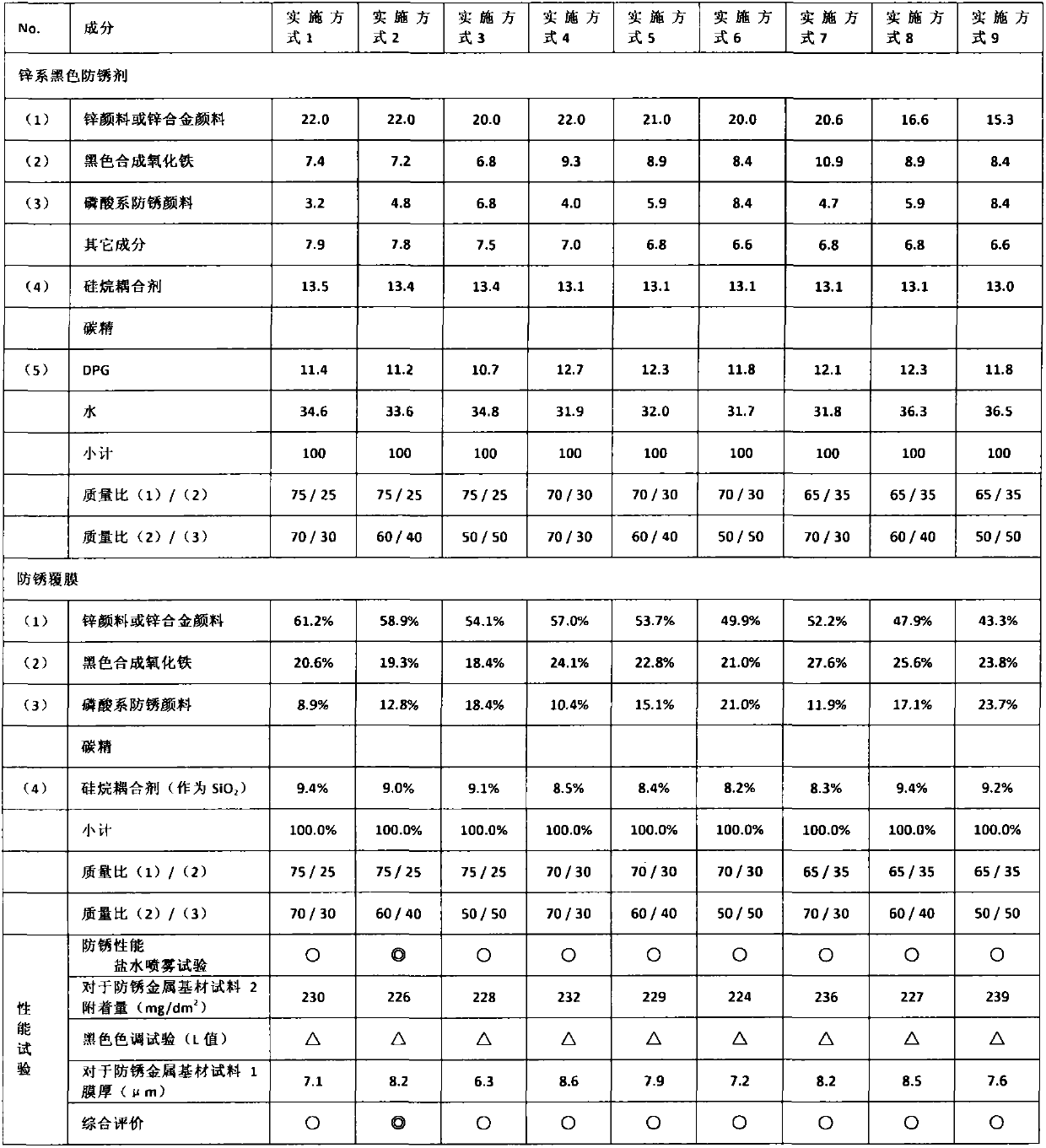

[0097] Except for the change in the combination shown in Table 1, the rust-proof metal base material sample 1 and the five rust-proof metal base material samples 2 were manufactured in the same manner as in the first embodiment.

[0098] [Table 1]

[0099]

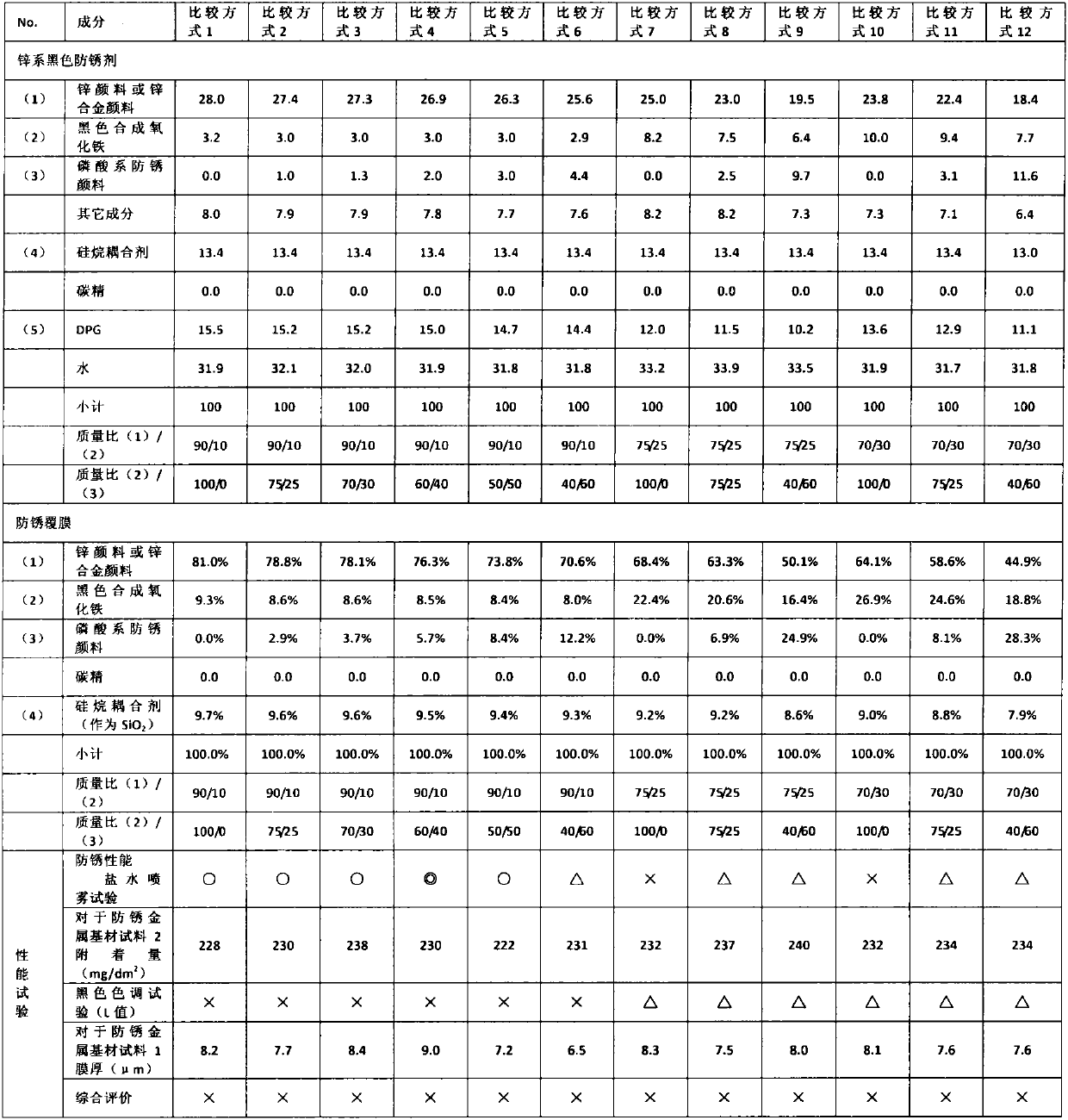

[0100] Comparison mode 1~35

[0101] Except for the changes in the combinations shown in Tables 2 to 4, in the same manner as in Embodiment 1, a rust-proof metal base material sample 1 and five rust-proof metal base material samples 2 were produced.

[0102] [Table 2]

[0103]

[0104] [table 3]

[0105]

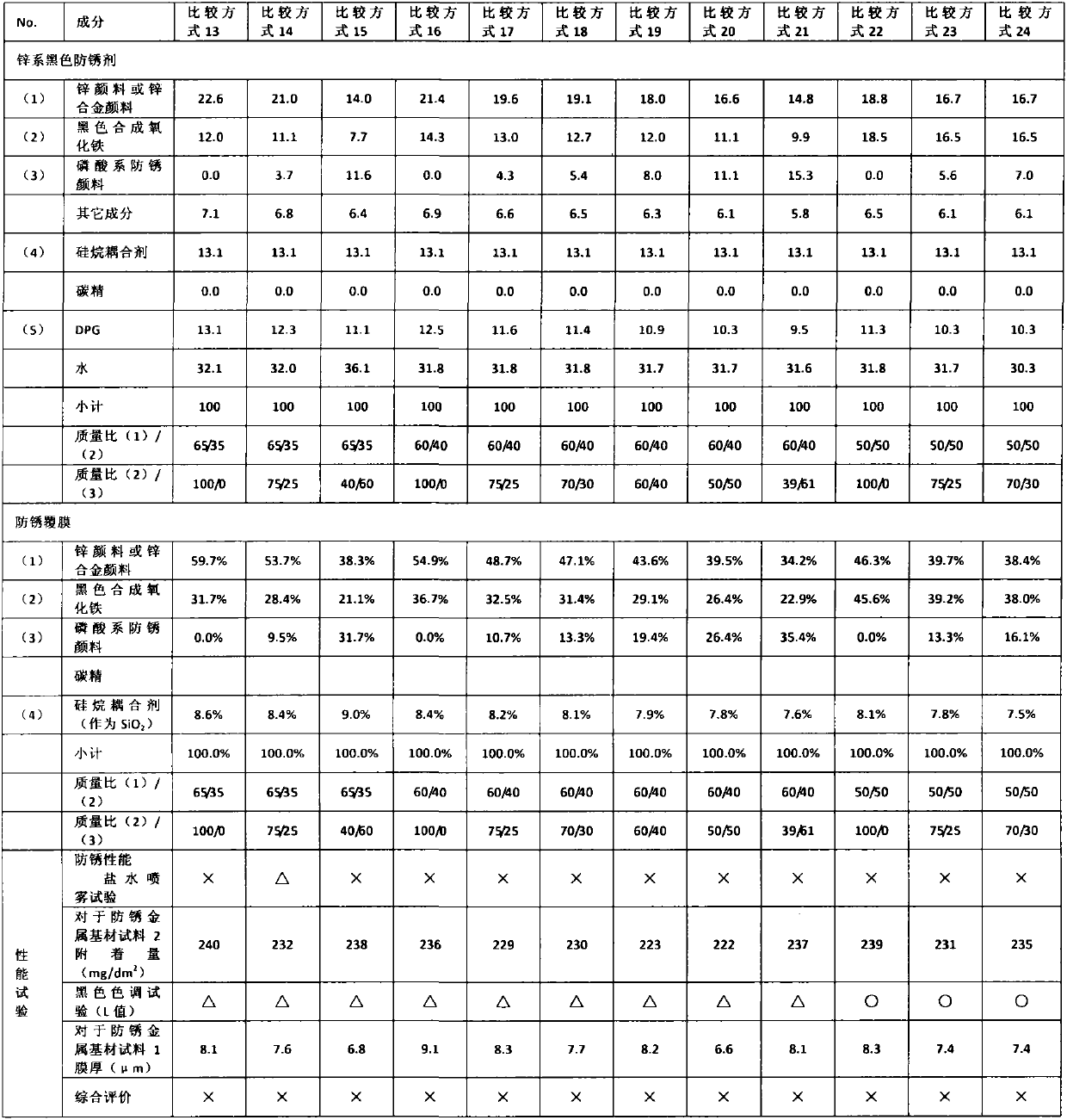

[0106] [Table 4]

[0107]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com