Method for purifying oil smoke-containing waste gas

A technology of oil fume and exhaust gas, applied in the field of compound microbial strains, can solve the problems of ineffective removal, frequent cleaning or replacement, and limited removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: plant essential oil to the removal of volatile organic compounds:

[0032] The used plant essential oil of the best embodiment of the present invention comprises terpenoids (Terpenoids, CAS#: 65996-98-7), yucca extract (Yucca Schidigera, CAS#: 223749-05-1) or their The resulting mixture is mixed in certain proportions.

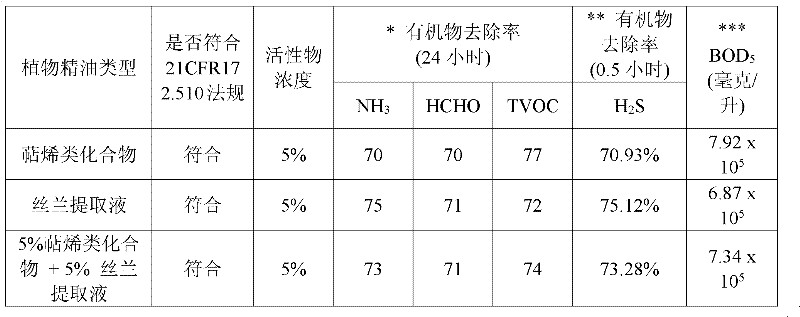

[0033] The removal rate of these plant essential oils to volatile organic compounds was tested, and the results are shown in Table 1.

[0034] Table 1 Plant essential oils to the removal rate of volatile organic compounds

[0035]

[0036] *NH 3 , HCHO, TVOC's decomposition capabilities adopt the industry standard "Indoor Air Cleanliness

[0037] Evaluation method for purification effect of chemical products (QB / T 2671-2006).

[0038] **H 2 The decomposition ability of S was determined by gas chromatography combined with a sulfur chemiluminescence detector (GC-SCD).

[0039] ***Plant essential oil BOD 5 The detection is carried o...

Embodiment 2

[0040] The composition of the composite microbial species in the treatment container is: calculated according to the proportion of the number of bacteria, 50% of Bacillus subtilis, 30% of Bacillus licheniformis, 10% of Bacillus cereus, 5% of Bacillus megaterium and 5% of Pseudomonas fluorescens. The composite microbial strains are loaded on a clay carrier and placed in a treatment container. The total number of initial colonies of composite microbial strains is 5.0X10 9 cfu / gram for a total weight of 500 grams.

[0041] The plant essential oil is atomized in the processing container: the mass fraction of terpenoids (Terpenoids) active ingredient is 20%, produced by Advance Chemicals Ltd, Canada, and the plant essential oil and tap water are prepared into a 5% dilution by using an automatic liquid mixing device.

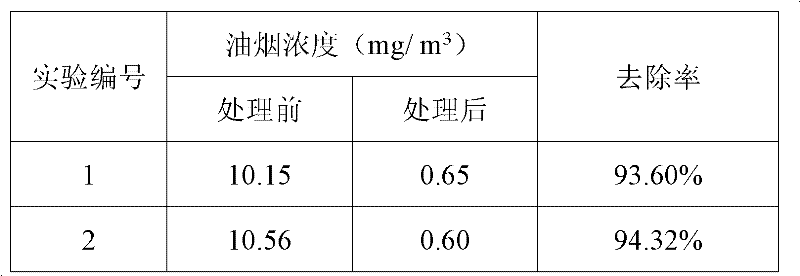

[0042] The plant essential oil dilution is continuously sprayed in the processing container space, the flow rate of the spray liquid is 100 ml / min, and the consumed ...

Embodiment 3

[0048] With embodiment 2, but the plant essential oil that adopts is as follows:

[0049] Yucca Schidigera extract (Yucca Schidigera), 50% active ingredient mass fraction before dilution, produced by Ultra Bio-Logics Inc, Canada, is prepared into a 5% active ingredient mass fraction dilution using an automatic liquid mixing device.

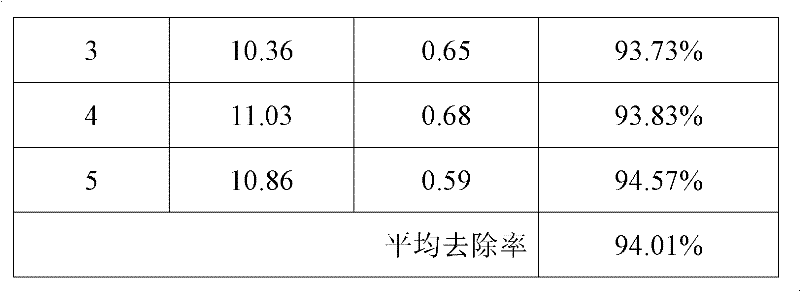

[0050] Sample collection and processing methods are exactly the same as in Example 2. The results are shown in Table 3.

[0051] The lampblack processing effect of table 3 embodiment 3

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com