Method for purifying oil smoke-containing waste gas

A technology for oil fume and exhaust gas, applied in the field of compound microbial strains, can solve the problems of limited removal effect, reduced efficiency and effect of purification equipment, and inability to effectively remove them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: plant essential oil to the removal of volatile organic compounds:

[0032] The used plant essential oil of the best embodiment of the present invention comprises terpenoids (Terpenoids, CAS#: 65996-98-7), yucca extract (Yucca Schidigera, CAS#: 223749-05-1) or their The resulting mixture is mixed in certain proportions.

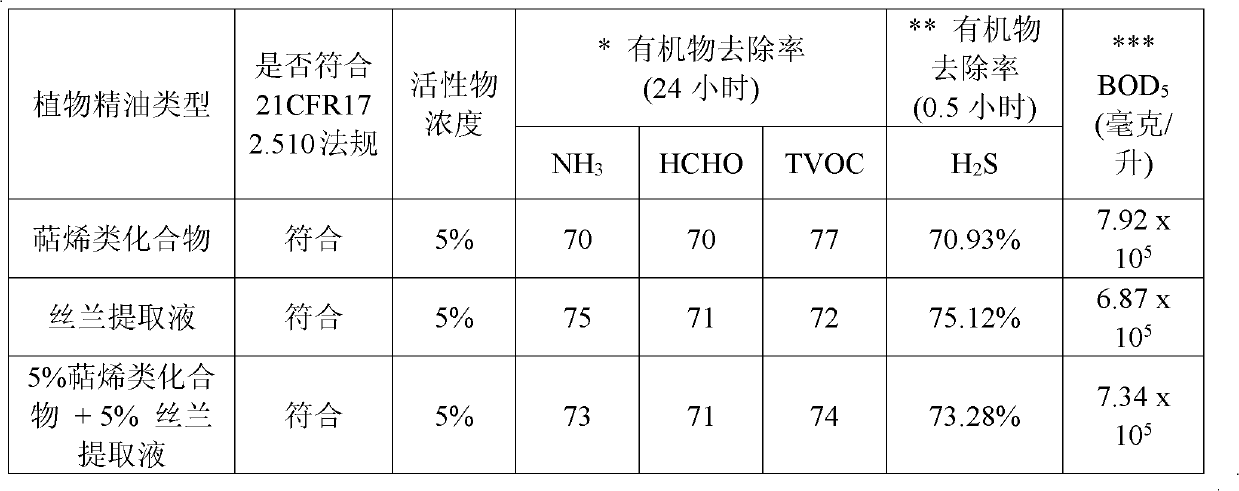

[0033] The removal rate of these plant essential oils to volatile organic compounds was tested, and the results are shown in Table 1.

[0034] Table 1 Plant essential oils to the removal rate of volatile organic compounds

[0035]

[0036] *NH 3 , HCHO, TVOC's decomposition capabilities adopt the industry standard "Indoor Air Cleanliness

[0037] Evaluation method for purification effect of chemical products (QB / T 2671-2006).

[0038] **H 2 The decomposition ability of S was determined by gas chromatography combined with a sulfur chemiluminescence detector (GC-SCD).

[0039] ***Plant essential oil BOD 5 The detection is carried o...

Embodiment 2

[0040] The composition of the composite microbial strains in the treatment container is: 50% of Bacillus subtilis, 30% of Bacillus licheniformis, 10% of Bacillus cereus, 5% of Bacillus megaterium and 5% of Pseudomonas fluorescens according to the proportion of the number of bacteria. The composite microbial strains are loaded on a clay carrier and placed in a treatment container. The total number of initial colonies of composite microbial strains is 5.0X10 9 cfu / gram for a total weight of 500 grams.

[0041] The plant essential oil is atomized in the treatment container: the mass fraction of terpenoids (Terpenoids) active ingredient is 20%, produced by Advance Chemicals Ltd, Canada, and the plant essential oil and tap water are prepared into a 5% dilution by using an automatic liquid mixing device.

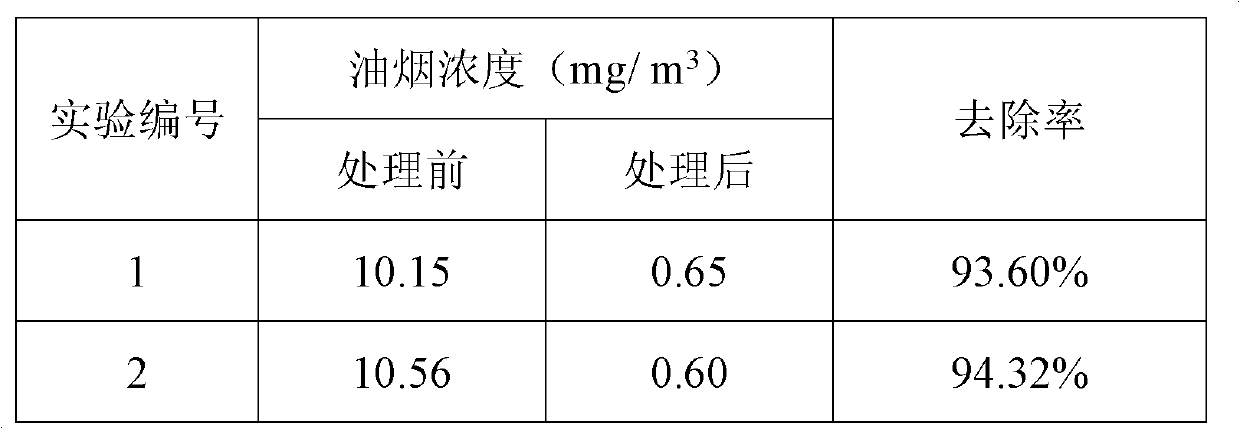

[0042] The plant essential oil dilution is continuously sprayed in the processing container space, the flow rate of the spray liquid is 100 ml / min, and the consumed plant essenti...

Embodiment 3

[0048] With embodiment 2, but the plant essential oil that adopts is as follows:

[0049] Yucca Schidigera extract (Yucca Schidigera), 50% active ingredient mass fraction before dilution, produced by Ultra Bio-Logics Inc, Canada, is prepared into a 5% active ingredient mass fraction dilution using an automatic liquid mixing device.

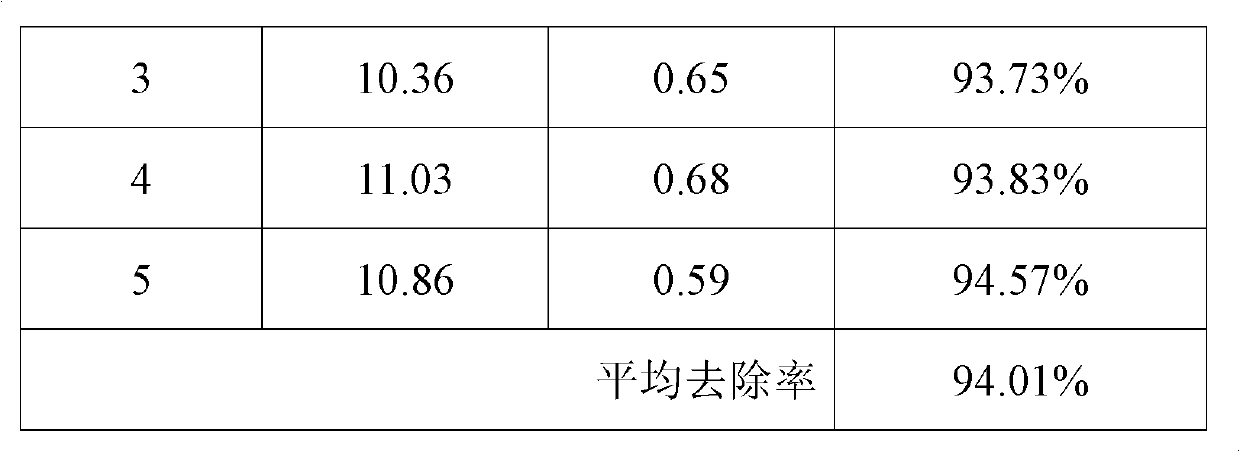

[0050] Sample collection and processing methods are exactly the same as in Example 2. The results are shown in Table 3.

[0051] The lampblack treatment effect of table 3 embodiment 3

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com