Steel plate with ultrahigh strength and ultrahigh toughness, and preparation method thereof

An ultra-high toughness, ultra-high strength technology, applied in the field of materials, can solve the problems of unsatisfactory strength and wear resistance, low tensile strength and tensile plasticity, poor processing performance, etc., and achieve a strong ability to absorb dislocations , strong applicability, good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

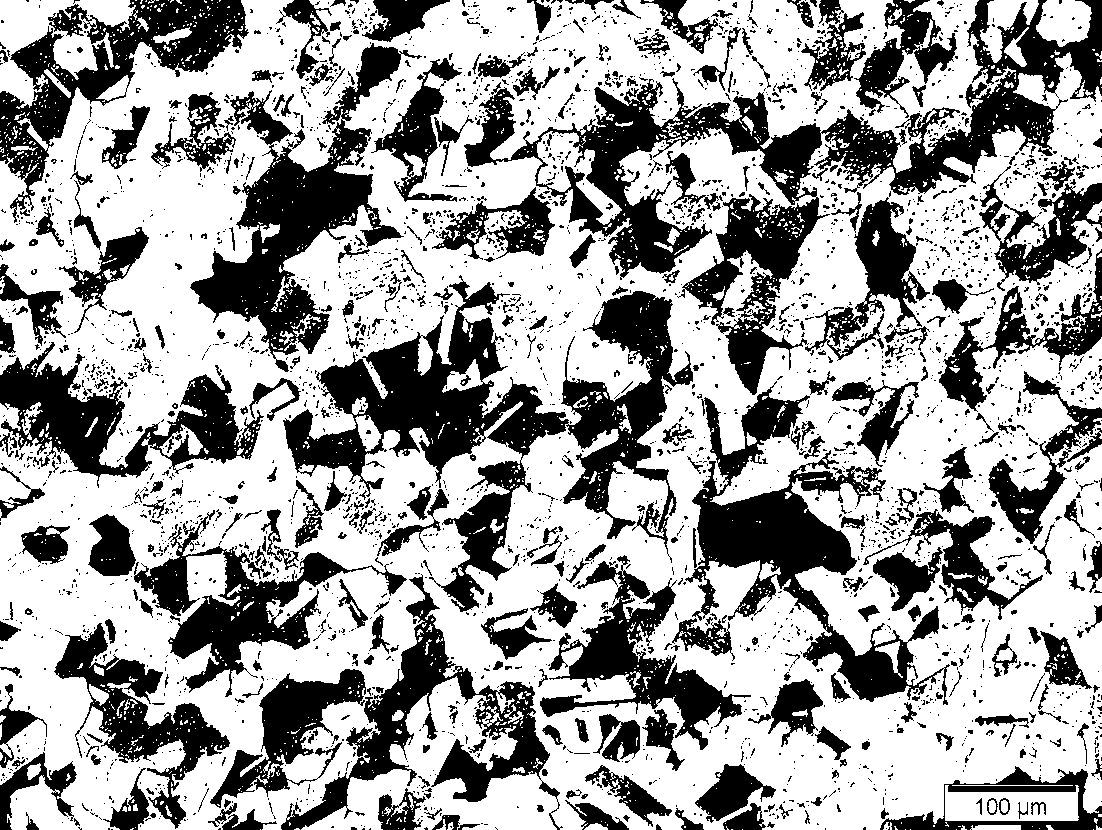

[0034] Metal Fe, metal Mn and C powder are placed in a melting furnace, smelted under the condition of argon, and then poured into ingots. The composition is Mn20.2%, C0.62% by weight, and the balance is Fe and unavoidable impurities;

[0035] The impurity components in the ingot are Si0.182% by weight, Al0.002%, Ni0.046%, Cu0.085%, Nb0.019%, V0.068%, Co0.013%, Ti0.004%, P0 .018%, B0.004%, W0.028%, N0.002%, S0.007%;

[0036] Heating the ingot to 1200±10°C for 1 hour for solution treatment, rolling at 1200±10°C for 6 passes, the deformation amount is 83%, and the final rolling temperature is 900±10°C; the austenite recrystallization zone Rolling is completed at 1050~1200°C, and deformation in the non-recrystallized zone is completed at 900~1000°C;

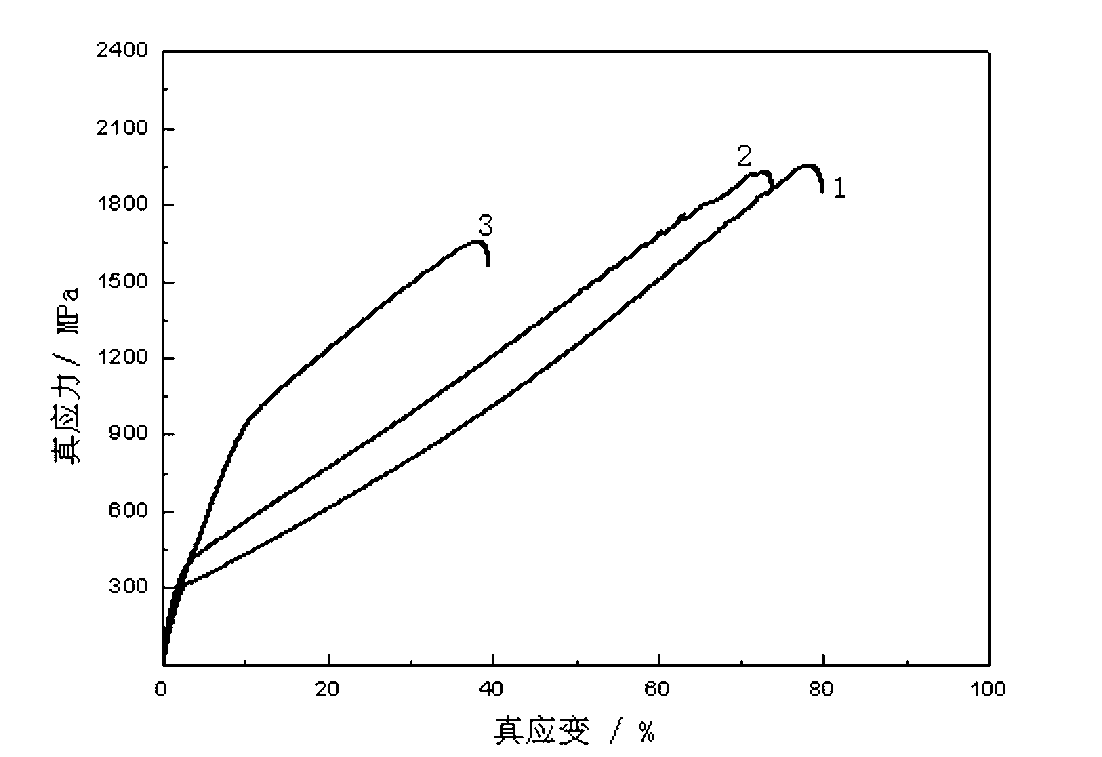

[0037] After rolling, the temperature was lowered to 820±10°C at a rate of 50°C / s, held for 0.5h, and then water-cooled to room temperature to obtain a steel plate with ultra-high strength and ultra-high toughness, with a tensile ...

Embodiment 2

[0040] Metal Fe, metal Mn and C powder are placed in a melting furnace, smelted under the condition of argon, and then poured into ingots. The composition is Mn20.1%, C0.63% by weight, and the balance is Fe and unavoidable impurities;

[0041] Heat the ingot to 1200±10°C for 2 hours for solution treatment, then roll it for 7 passes at 1200±10°C, the deformation is 84%, and the final rolling temperature is 900±10°C;

[0042] After rolling, cool down to 820±10°C at a rate of 60°C / s, hold for 0.8h, and then water-cool to room temperature to obtain a steel plate with ultra-high strength and ultra-high toughness; the tensile strength is 1960 MPa, and the tensile ductility is 80 %, the yield strength is 360MPa;

[0043] The steel plate with ultra-high strength and ultra-high toughness is cold-rolled with a deformation of 30%; then the temperature is raised to 750±10°C and kept for 10 minutes. The tensile strength of the cold-rolled steel plate is 1930 MPa, the tensile ductility is ...

Embodiment 3

[0046] Metal Fe, metal Mn and C powder are placed in a melting furnace, smelted under the condition of argon, and then poured into ingots. The composition is Mn20.3%, C0.61% by weight, and the balance is Fe and unavoidable impurities;

[0047] Heating the ingot to 1200±10°C for 3 hours for solution treatment, rolling at 1200±10°C for 8 passes, the deformation is 85%, and the final rolling temperature is 900±10°C;

[0048] After rolling, the temperature is lowered to 820±10°C at a rate of 80°C / s, kept for 1 hour, and then water-cooled to room temperature to obtain a steel plate with ultra-high strength and ultra-high toughness; the tensile strength is 1910MPa, and the tensile ductility is 75%. The yield strength is 400MPa;

[0049] The steel plate with ultra-high strength and ultra-high toughness was cold-rolled, and the deformation amount was 20%. Finally, the temperature was raised to 650±10°C and kept for 2 minutes. The tensile strength of the obtained cold-rolled steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com