A ferritic steel plate strengthened by nano-scale spherical cementite and its preparation method

A ferrite and cementite technology, applied in the field of metallurgy, can solve the problems of inability to meet the impact resistance of the transportation and manufacturing industry, inability to industrially promote, and high processing costs, and achieves suppression of migration and growth. The effect of good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

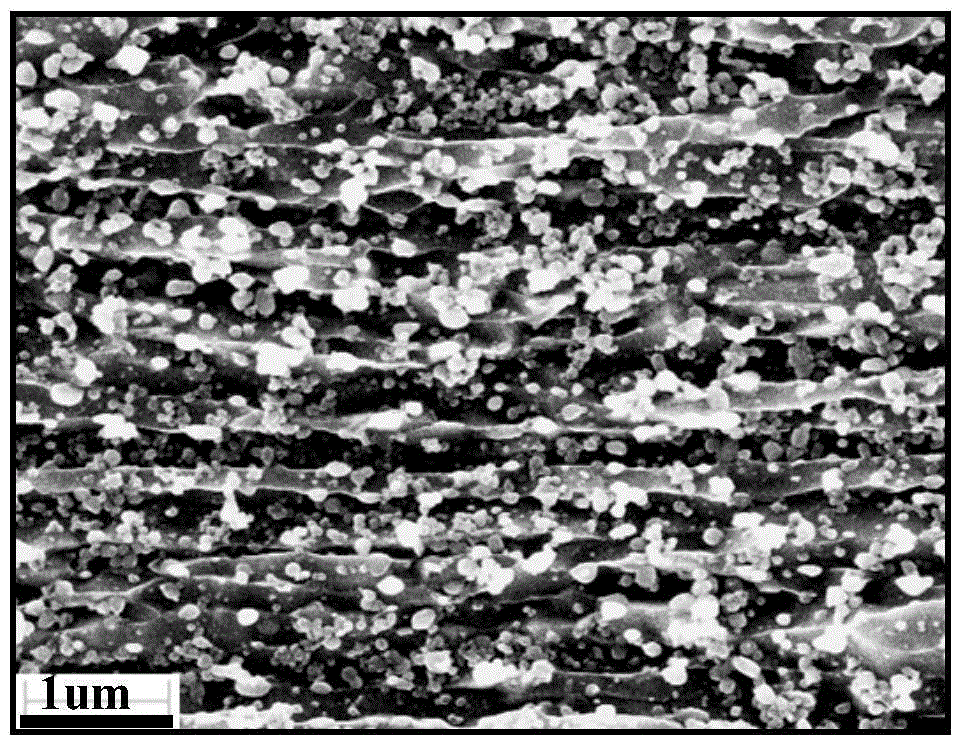

[0047] Nanoscale spherical cementite strengthened ferritic steel plate, chemical composition by mass percentage: Cr: 1.05%, Mo: 1.00%, Mn: 0.72%, Ni: 0.60%, Al: 0.45%, C: 0.42%, The balance is Fe and unavoidable impurities; the microstructure of the ferritic steel plate is equiaxed ferrite grains, nano-scale spherical cementite is dispersed in the ferrite grain boundary area, and the diameter of the grains is 0.4-0.5 μm , the size of nano-scale spherical cementite is 70-80nm; the thickness of ferritic steel plate is 1.7mm.

[0048] The preparation method of the nanoscale spherical cementite strengthened ferritic steel plate comprises the following steps:

[0049] Step 1, smelting:

[0050] According to the chemical composition of the nano-scale spherical cementite-strengthened ferritic steel sheet, it is melted under the protection of argon at a melting temperature of 1500 ° C, and cast into an ingot;

[0051] The impurity components in the ingot are as follows: Cu: 0.02%, S...

Embodiment 2

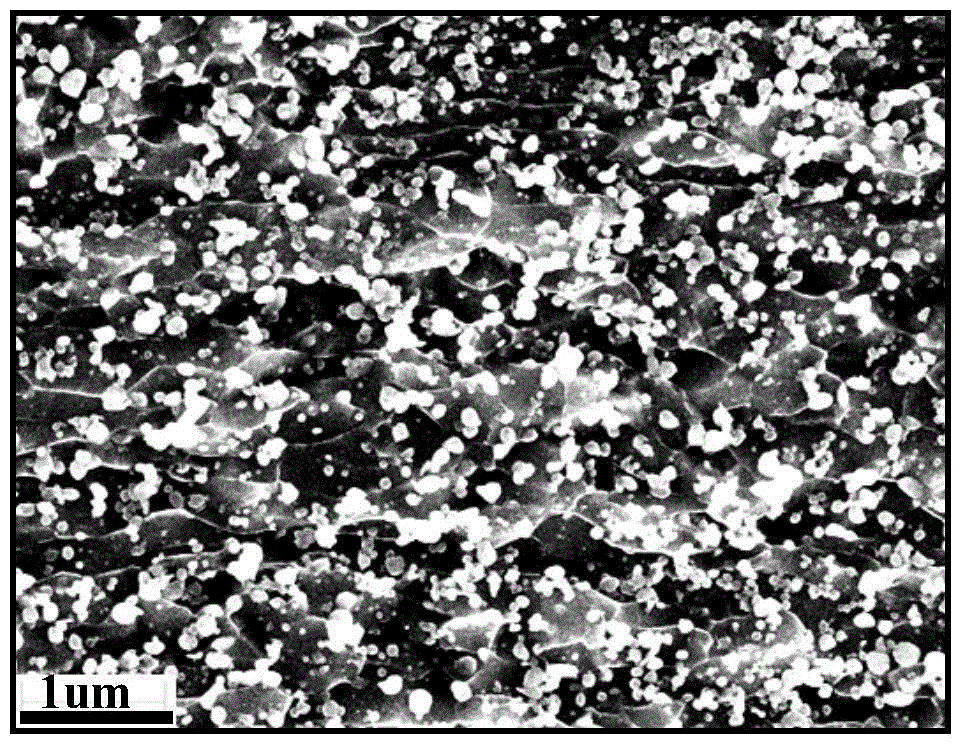

[0064] Nano-scale spherical cementite strengthened ferritic steel plate, chemical composition by mass percentage: Cr: 1.00%, Mo: 0.97%, Mn: 0.75%, Ni: 0.57%, Al: 0.52%, C: 0.45%, The balance is Fe and unavoidable impurities; the microstructure of the ferritic steel plate is equiaxed ferrite grains, nano-scale spherical cementite is dispersed in the ferrite grain boundary area, and the diameter of the grains is 0.5-0.6 μm , the size of nano-scale spherical cementite is 90-100nm; the thickness of ferritic steel plate is 2mm.

[0065] The preparation method of the nanoscale spherical cementite strengthened ferritic steel plate comprises the following steps:

[0066] Step 1, smelting:

[0067] According to the chemical composition of the nano-scale spherical cementite-strengthened ferritic steel sheet, it is melted under the protection of argon at a melting temperature of 1525°C and cast into an ingot;

[0068] The impurity components in the ingot are as follows: Cu: 0.03%, Si: ...

Embodiment 3

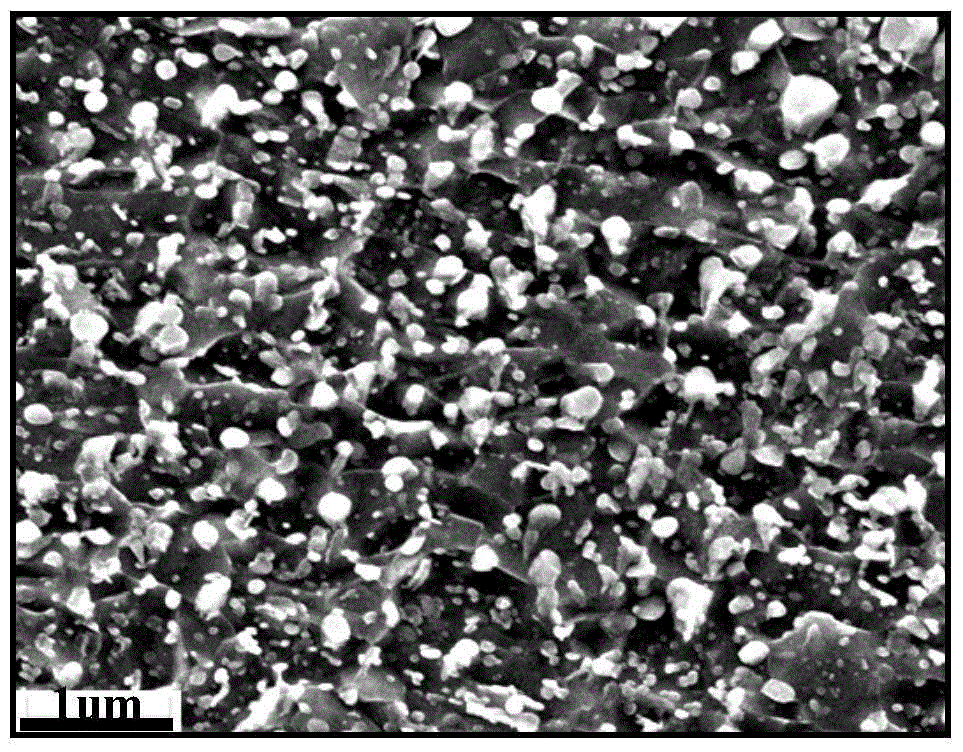

[0081] Nanoscale spherical cementite strengthened ferritic steel plate, chemical composition by mass percentage: Cr: 1.00%, Mo: 0.97%, Mn: 0.75%, Ni: 0.57%, Al: 0.37%, C: 0.39%, The balance is Fe and unavoidable impurities; the microstructure of the ferritic steel plate is equiaxed ferrite grains, nano-scale spherical cementite is dispersed in the ferrite grain boundary area, and the diameter of the grains is 2 to 3 μm. The size of nanoscale spherical cementite is 130-150nm; the thickness of ferritic steel plate is 1.4mm.

[0082] The preparation method of the nanoscale spherical cementite strengthened ferritic steel plate comprises the following steps:

[0083] Step 1, smelting:

[0084] According to the chemical composition of the nano-scale spherical cementite-strengthened ferritic steel sheet, it is melted under the protection of argon at a melting temperature of 1550 ° C, and cast into an ingot;

[0085] The impurity components in the ingot are as follows: Cu: 0.01%, Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com