Calibration apparatus for laser micro energy

A micro-energy and laser technology, applied in the field of optical metrology, can solve the problem of difficult separation of laser signal and electromagnetic noise, stray light noise, etc., and achieve the effects of stable waveform, avoiding high-frequency noise, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

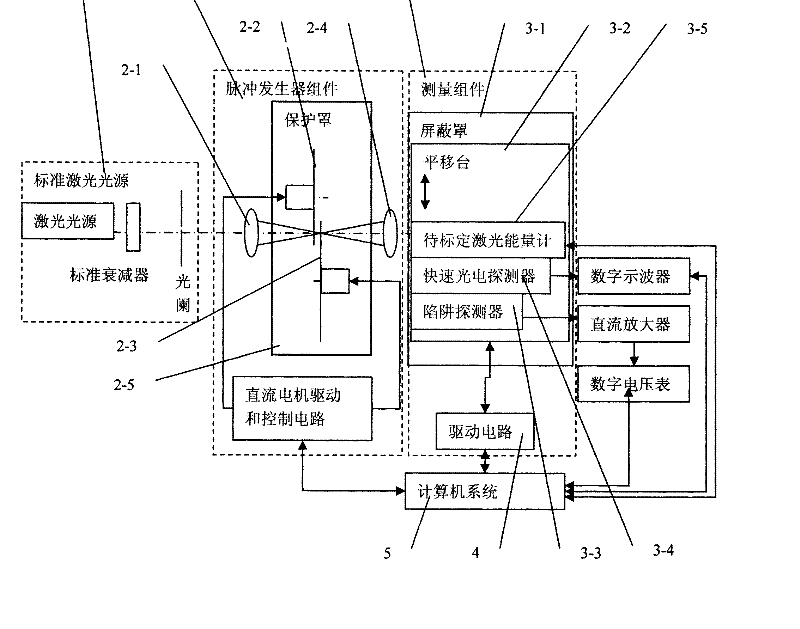

[0019] according to figure 1 As shown, the laser micro-energy standard device in the preferred embodiment of the present invention includes a standard laser light source 1, a pulse generator assembly 2, a measurement assembly 3, a drive circuit 4, a computer system 5 equipped with a laser micro-energy calibration software package, and a standard laser The light source 1, the pulse generator assembly 2, and the measurement assembly 3 are placed on a grounded optical platform. The standard laser light source 1 is a continuous laser with a wavelength of 1.06 μm, or a continuous laser with a wavelength of 0.532 μm, 0.905 μm, 10.6 μm or other wavelengths.

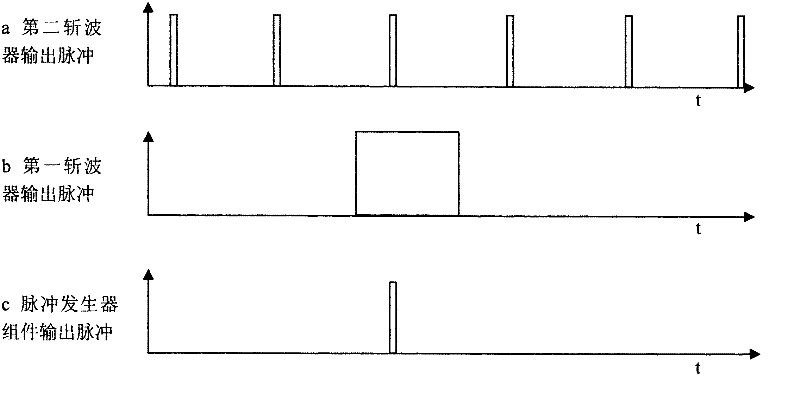

[0020]The pulse generator assembly 2 includes a focusing lens 2-1, a first chopper 2-2, a second chopper 2-3, a collimating lens 2-4, a protective cover 2-5, a DC motor drive and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com