Laminated composite solder

A layered composite and composite solder technology, which is applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems that are not easy to be formed into thin strips or ribbons, limited precious metal resources, and restricted use, etc., to achieve Save the amount of precious metals, meet the performance requirements, and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

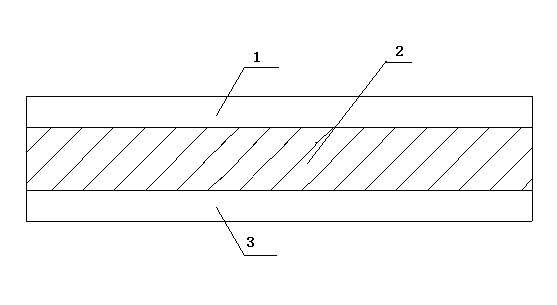

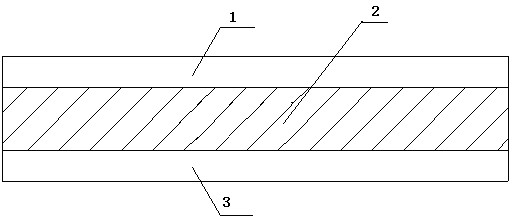

Image

Examples

Embodiment 1

[0019] The middle layer metal is oxygen-free copper strip, and the upper and lower layer metals are AgCu 28 (or AgCu 10 、AgCu 15 、AgCu 50 etc.) alloy strip. Cut the strips into equal widths, clean the surface of the strips, stack them for rolling and compounding, and then roll them to a thickness of 0.1mm after diffusion annealing. The thickness ratio of the upper, middle and lower layers is 1:4 :1 (or 1:3:1, 1:2:1), to obtain layered composite solder.

Embodiment 2

[0021] The middle layer metal is oxygen-free copper strip, and the upper and lower layer metals are AgCu 50 Ni 0.4 alloy strip. Cut the strips into equal widths, clean the surface of the strips, stack them for rolling and compounding, and then roll them to a thickness of 0.1mm after diffusion annealing. The thickness ratio of the upper, middle and lower layers is 1:2.5 : 1, to obtain layered composite solder.

Embodiment 3

[0023] The middle layer metal is CuAg 7 Alloy strip, the upper and lower layer metal is AgCu 27 In 10 alloy strip. Cut the strips into equal widths, clean the surface of the strips, stack them for rolling and compounding, and then roll them to a thickness of 0.1mm after diffusion annealing. The thickness ratio of the upper, middle and lower layers is 1:5 : 1, to obtain layered composite solder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com