Bamboo-wood composite container base plate with improved bamboo curtain splint surface layers, and manufacturing method thereof

A container bottom plate, bamboo-wood composite technology, applied in lamination devices, wood layered products, chemical instruments and methods, etc., can solve the problems of multiple labor costs, energy consumption, materials and labor, and high costs, and achieve fast growth, The effect of long-term use and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

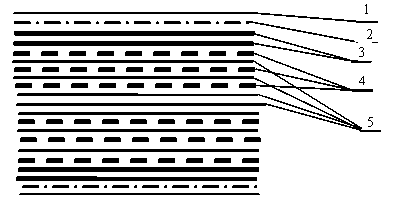

[0024] structured as figure 1 ,

[0025] The manufacturing method of the bamboo-wood composite container floor with the improved bamboo curtain as the surface layer is as follows:

[0026] a. Sorting and finishing of wooden veneers and bamboo curtains, the moisture content of wooden veneers is ≤10%, and double-sided glue is applied according to the requirements, and the amount of glue applied is 350g / m 2 , add 15% flour filler to the glue, age or dry at low temperature; improve the bamboo curtain to be a special equal-width bamboo piece and weave it into a bamboo curtain (or use a few thin wooden veneers to glue the tight bamboo pieces together) , and dry all the bamboo curtains to a moisture content of less than 12%, after impregnating the phenolic glue, dry at a low temperature to a moisture content of less than 20%, and add 2.4 grams of insecticide to the glue for 1 kg of glue (solid content 45%);

[0027] b. Blank assembly, from outside to inside: one layer of phenolic i...

Embodiment 2

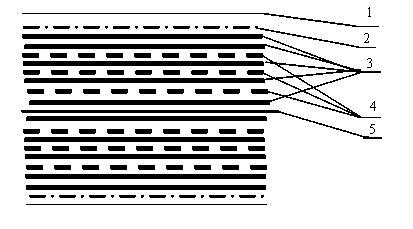

[0035] The structure of the bamboo-wood composite container floor with the improved bamboo curtain as the surface layer is as follows: figure 2 ,

[0036] The manufacturing method of the bamboo-wood composite container floor with the improved bamboo curtain as the surface layer is as follows:

[0037] a. Sorting and finishing of wooden veneers and bamboo curtains. The moisture content of wooden veneers is ≤10%. Glue is applied on both sides according to the requirements, and the amount of glue applied is 250g / m 2 , add 15% flour filler to the glue, age or dry at low temperature; improve the bamboo curtain to be a special equal-width bamboo piece and weave it into a bamboo curtain (or use a few thin wooden veneers to glue the tight bamboo pieces together) , and dry all the bamboo curtains to a moisture content of less than 12%, after impregnating the phenolic glue, dry at a low temperature to a moisture content of less than 20%, and add 2.4 grams of insecticide to the glue fo...

Embodiment 3

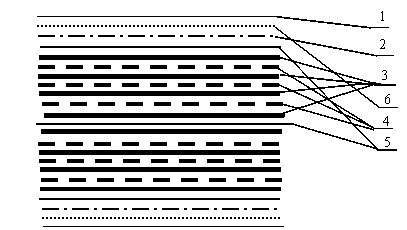

[0046] The structure of the bamboo-wood composite container floor with the improved bamboo curtain as the surface layer is as follows: image 3 ,

[0047] The manufacturing method of the bamboo-wood composite container floor with the improved bamboo curtain as the surface layer is as follows:

[0048] a. Sorting and finishing of wooden veneers and bamboo curtains, the moisture content of wooden veneers is ≤10%, and double-sided glue is applied according to the requirements, and the amount of glue applied is 300g / m 2 , add 15% flour filler to the glue, age or dry at low temperature; improve the bamboo curtain to be a special equal-width bamboo piece and weave it into a bamboo curtain (or use a few thin wooden veneers to glue the tight bamboo pieces together) , and dry all the bamboo curtains to a moisture content of less than 10%, after impregnating the phenolic glue, dry at a low temperature to a moisture content of less than 20%, and add 2.4 grams of insecticide to the glue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com