Radial runout detecting device of combining gear tooth part of automobile

A radial runout and detection device technology, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems that conventional inspection tools cannot be effectively inspected, are not suitable for on-line inspection, and have high measurement conditions, and achieve convenient measurement. The effect of simplicity and short auxiliary man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to accompanying drawing.

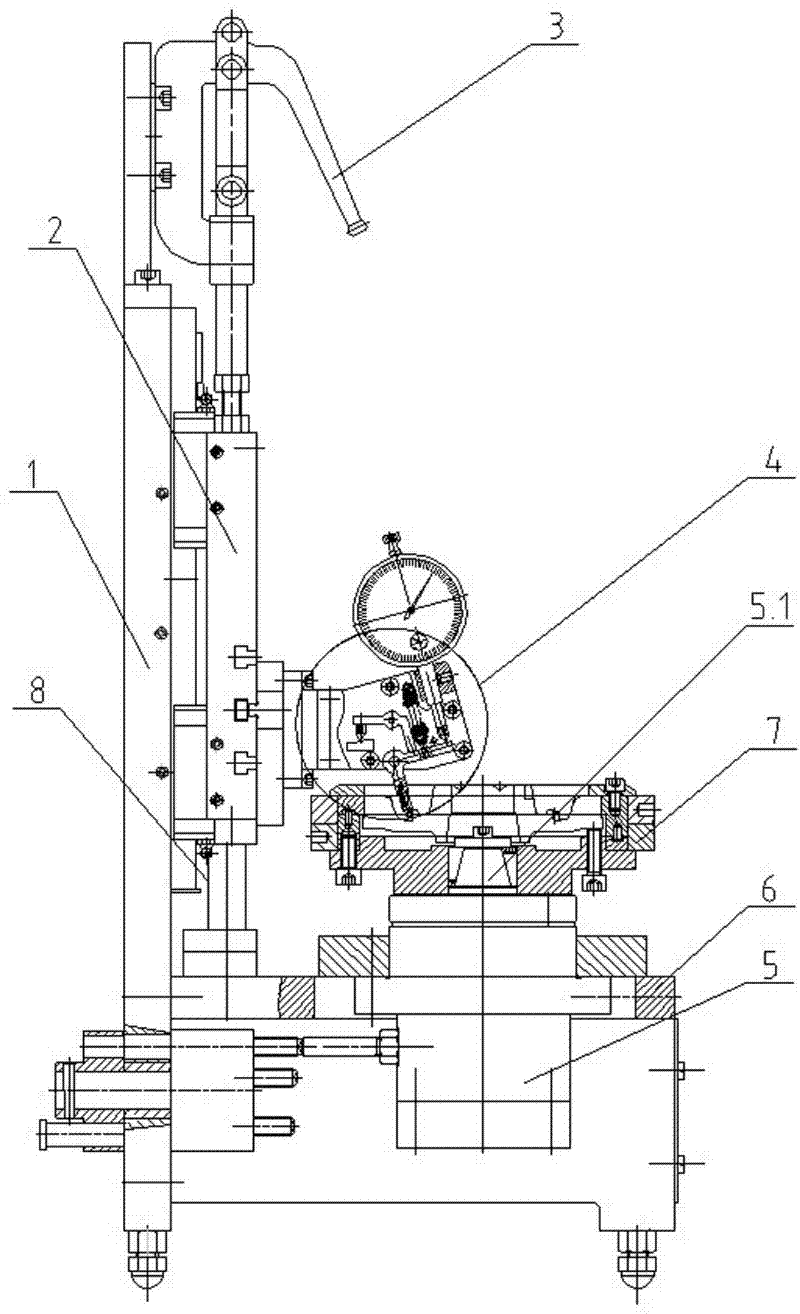

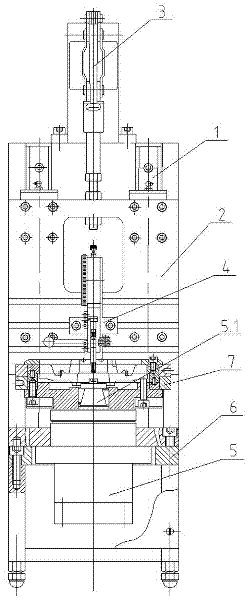

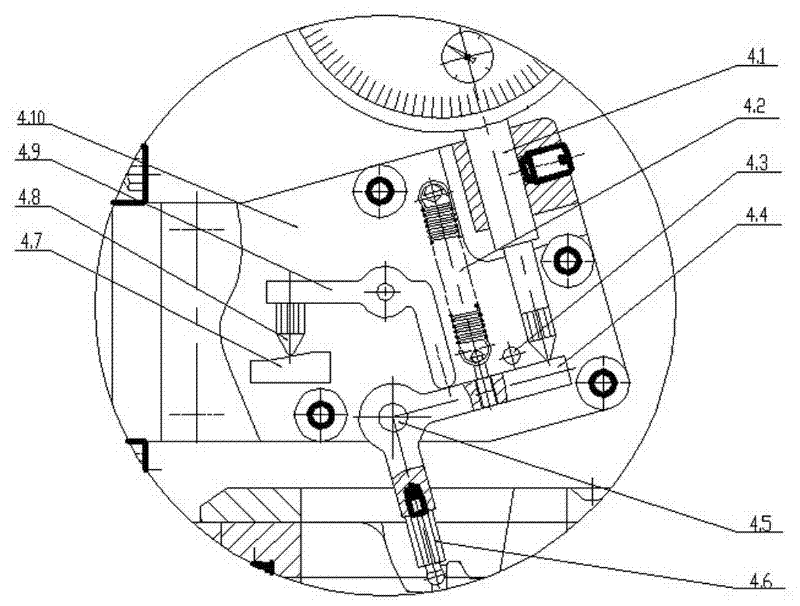

[0016] figure 1 , figure 2 The radial runout detection device of a combined gear tooth of an automobile is shown, which includes three parts: a vertical track structure, a workbench and a measuring mechanism. The vertical track structure is a manual reciprocating straight structure. The skateboard 2 cooperates with a pair of upright rails and moves straight up and down through the handle 3. Pull the handle 3 upward to drive the skateboard 2 to move upward, and move the handle 3 downward to make the skateboard move up and down. 2 moves down, and the down limit position of slide plate 2 is limited by limit post 8. A transverse T-shaped slot for installing the measuring mechanism 4 is left on the front of the slide plate 2 . The workbench is placed flat on the bottom of the track 1 and connected to each other as a whole. The workbench includes a rotor 5, a base 6 and a positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com