Semiconductor device and method for fabricating semiconductor device

A semiconductor and component technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as large silicon, improve reliability, increase pass rate, and increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

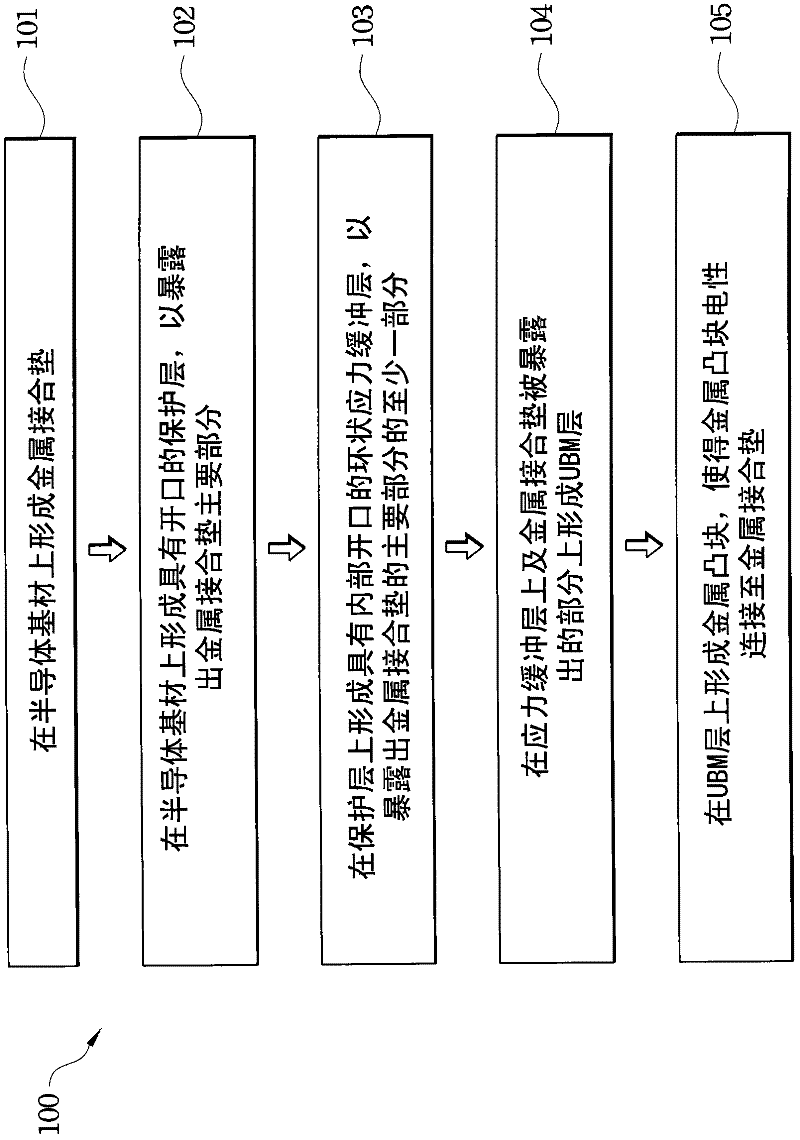

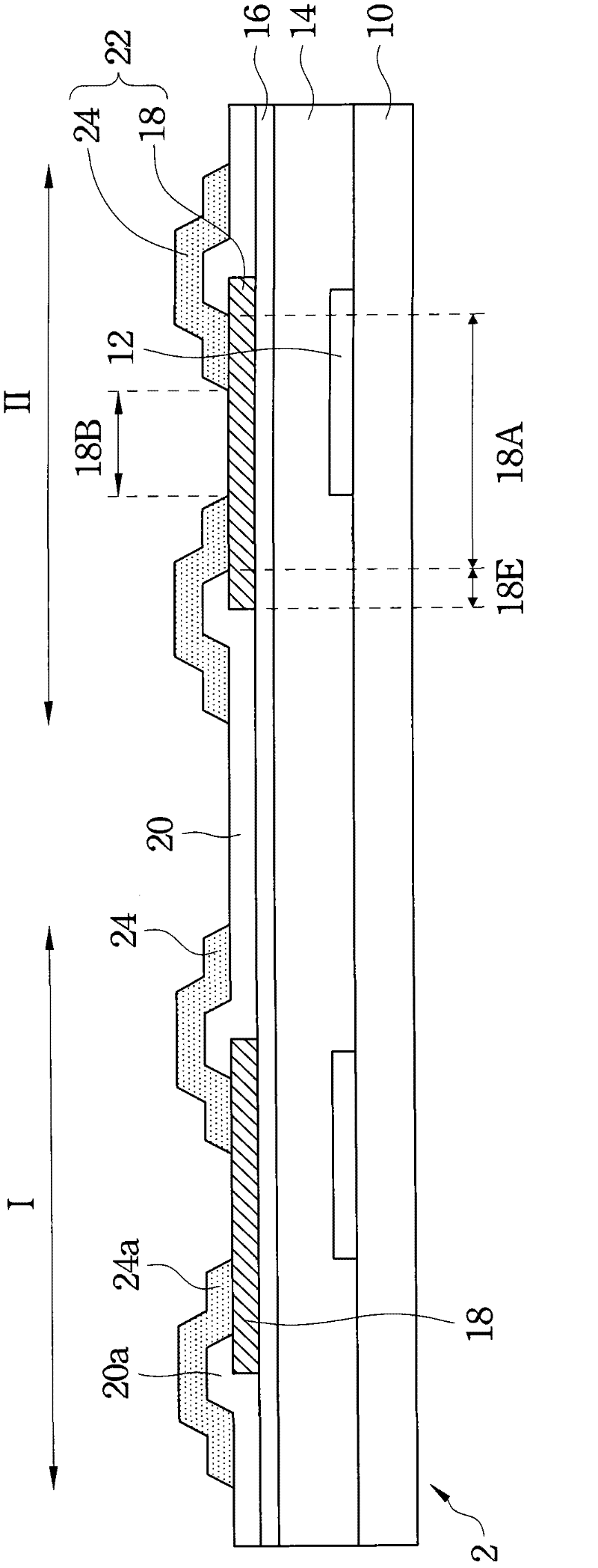

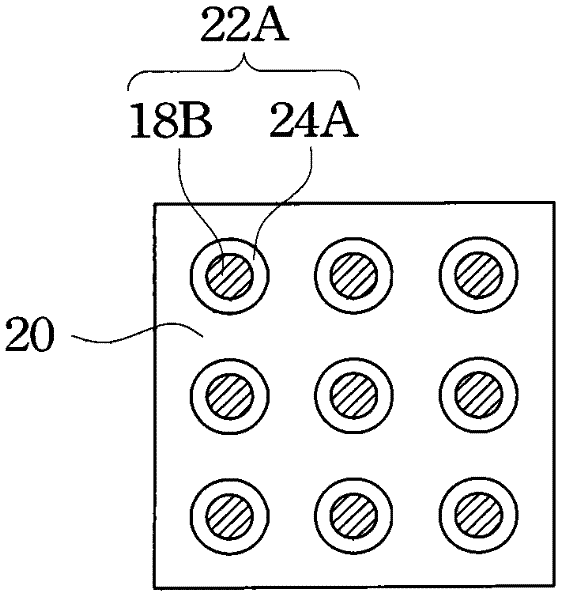

[0048] The invention provides a semiconductor component with a bonding pad structure and a process for forming the semiconductor component, wherein the bonding pad structure is provided with a stress buffer layer. The above-mentioned semiconductor components may have copper pillars, pillar protection (Passivation) interconnection lines, solder bumps, and / or through-silicon vias (TSVs) fabricated therein, wherein the semiconductor components may be applied to overlay Assembly, WLCSP, three-dimensional integrated circuit (3D-IC) stacking, and / or any advanced packaging technology field. A detailed description will be given below with reference to exemplary embodiments in the corresponding drawings. Wherever possible, the same reference numbers are used in the drawings and description to refer to the same or like parts. In the drawings, shapes and thicknesses may be exaggerated for clarity and convenience. The invention is to be directed in particular to components which form pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com