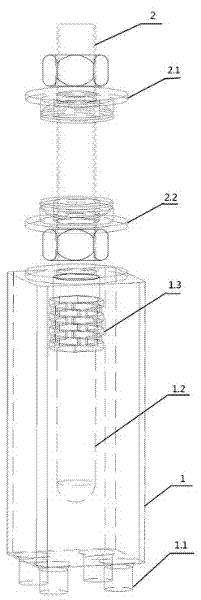

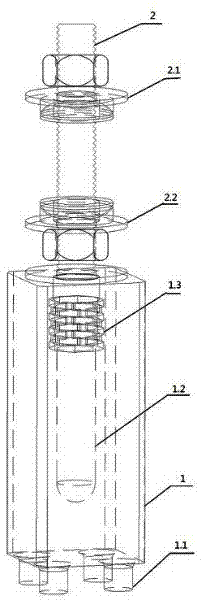

Aluminum carbon bale roughing slag controller used for continuous casting

A controller, aluminum carbon technology, applied in the direction of casting molten material container, casting equipment, manufacturing tools, etc., can solve the problems affecting the quality of casting slab, and achieve the effect of ensuring the quality of casting slab and preventing vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] The control block (1) of the aluminum carbon ladle slag controller for continuous casting is made of aluminum carbon, and its composition and content are: flake graphite 30wt%, metal silicon powder 4wt%, silicon carbide powder 3wt%, sintered Corundum 30wt%, brown corundum 21wt%, phenolic resin 12wt%. The raw materials with the above proportions are made into blanks, added to the rubber sleeve of the forming mold matched with the control block (1), and the inner wire iron nut (1.3) is preset, compacted, sealed, and formed by cold isostatic pressing . The molding pressure is 50MPa, and the holding time is 10min. The formed green body is then processed by simple turning to make it conform to the drawing size. After drying at a temperature of 230°C, the surface is coated with an anti-oxidation coating, and placed in a special kiln for heat treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com