Liquid-crystal active monomer for polyimide surface of alignment film and liquid crystal panel

An active monomer, polyimide technology, applied in liquid crystal materials, nonlinear optics, instruments, etc., can solve the problem of large interaction force, uneven display of liquid crystal panel dripping graphics, uneven deposition of liquid crystal active monomer 1, etc. problems, to improve the curing speed and improve the uneven display of dripping graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the examples, and the examples are intended to explain rather than limit the technical solution of the present invention.

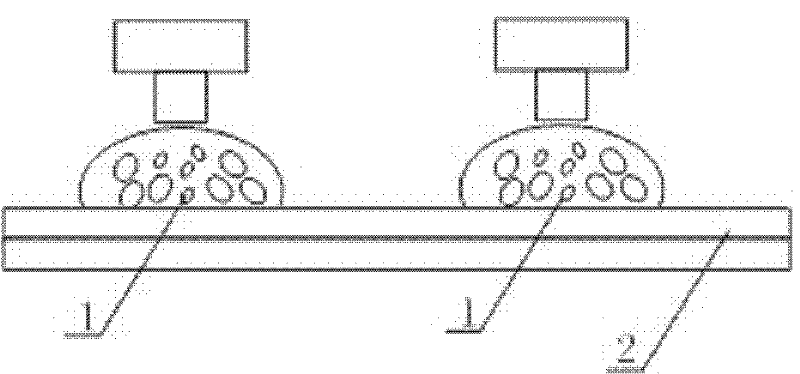

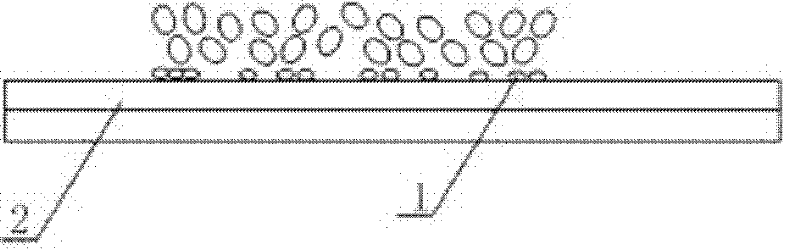

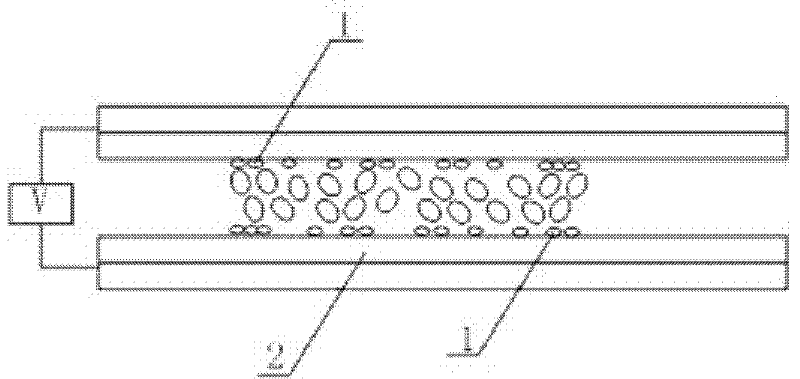

[0028] According to a preferred embodiment of the present invention, the present invention provides a liquid crystal active monomer, the liquid crystal active monomer is included in the liquid crystal composition, and is used to make the liquid crystal molecules in the liquid crystal composition have a pretilt angle, so The molecular weight of the liquid crystal active monomer is between 322 and 500, and the wavelength of ultraviolet light required for polymerization and curing of the liquid crystal active monomer on the surface of the polyimide is greater than or equal to 300 nanometers.

[0029] In the present invention, the liquid crystal composition preferably refers to the liquid crystal composition of drop-filling (ODF) technology, which is used to make the liquid crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com