Regeneration method of waste acid in polysilicon texturing process and waste acid regeneration system

A polysilicon and acid regeneration technology, which is applied in crystal growth, chemical instruments and methods, and after treatment, can solve the problems of acid waste and high cost, and achieve the effects of low power consumption, cost saving, and no sludge generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example is used to illustrate the regeneration method of waste acid in the polysilicon texturing process disclosed in the present invention.

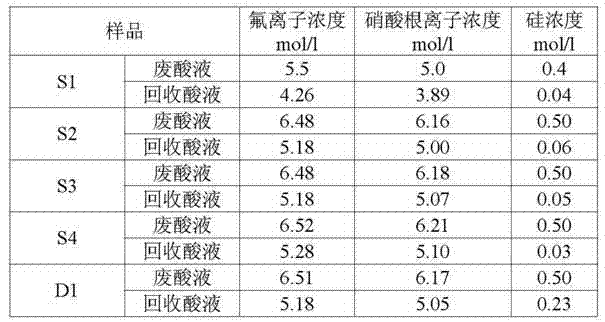

[0045] Take 1000L of waste acid solution produced in the polysilicon texturing process, and measure the concentration of fluorine ion in it to be 5.5mol / l, the concentration of nitrate ion to be 5mol / l, and the concentration of hexafluorosilicate ion to be 0.4 mol / l, put the above waste acid solution in the waste acid storage tank.

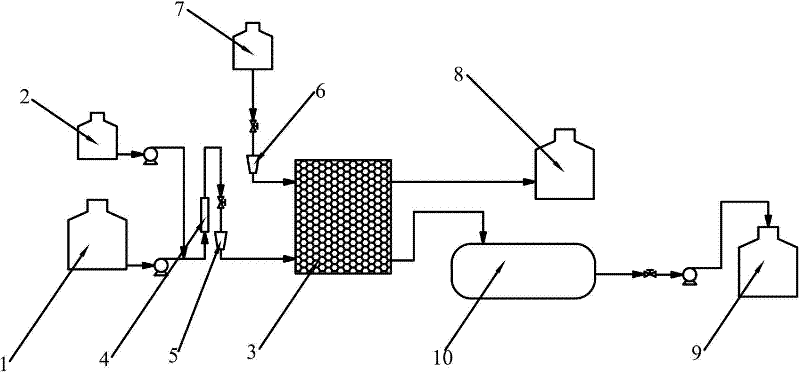

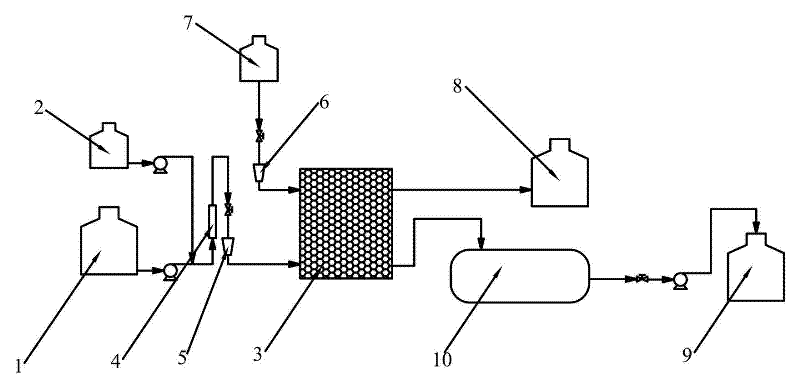

[0046] Take 2180mol ethylenediaminetetraacetic acid and place it in the complexing agent storage tank. use figure 1 The system shown is separated. Mix the waste acid liquid in the waste acid storage tank with the ethylenediaminetetraacetic acid in the complexing agent storage tank to obtain a mixed solution, then inject the mixed solution into the first channel of the diffusion dialyzer, and inject deionized water into the diffusion dialyzer the second channel. Control the liquid flow rate i...

Embodiment 2

[0049] This example is used to illustrate the regeneration method of waste acid in the polysilicon texturing process disclosed in the present invention.

[0050] Get 1000L of waste acid solution produced in the polysilicon texturing process, measure wherein the concentration of fluorine ion is 6.48mol / l, the concentration of nitrate ion is 6.16mol / l, according to the amount of silicon atoms, the concentration of hexafluorosilicate complex ion is 0.50mol / l, put the above waste acid solution in the waste acid storage tank.

[0051] Get 500mol acetylacetone and place complexing agent storage tank. use figure 1 The system shown is separated. Mix the waste acid liquid in the waste acid storage tank with the ethylenediaminetetraacetic acid in the complexing agent storage tank to obtain a mixed solution, then inject the mixed solution into the first channel of the diffusion dialyzer, and inject deionized water into the diffusion dialyzer the second channel. Control the liquid flo...

Embodiment 3

[0054] This example is used to illustrate the regeneration method of waste acid in the polysilicon texturing process disclosed in the present invention.

[0055] Get 1000L of waste acid solution produced in the polysilicon texturing process, measure wherein the fluoride ion concentration is 6.48mol / l, the nitrate ion concentration is 6.18mol / l, according to the amount of silicon atoms, the hexafluorosilicate complex ion concentration is 0.50mol / l, put the above waste acid solution in the waste acid storage tank.

[0056] Get 1500mol 2-methyl-8-hydroxyquinoline and place it in a complexing agent storage tank. use figure 1 The system shown is separated. Mix the waste acid liquid in the waste acid storage tank with the ethylenediaminetetraacetic acid in the complexing agent storage tank to obtain a mixed solution, then inject the mixed solution into the first channel of the diffusion dialyzer, and inject deionized water into the diffusion dialyzer the second channel. Control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com