Method for modifying surface by adopting remote plasmas

A remote plasma and surface modification technology, applied in the field of ion surface modification, can solve problems such as material performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

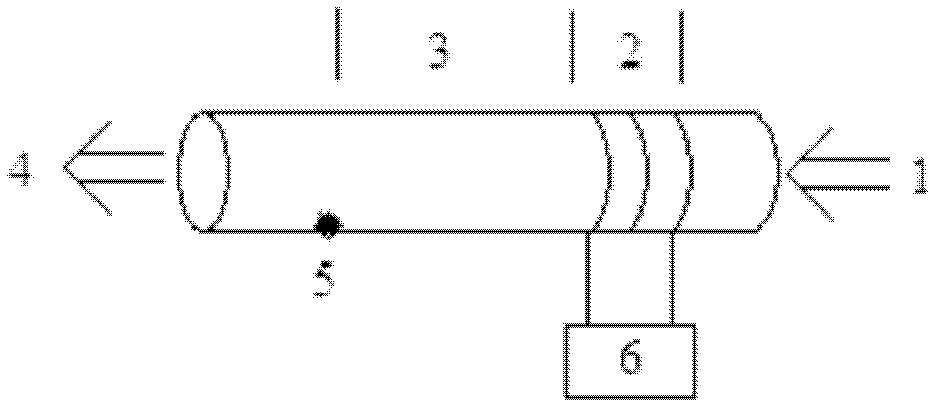

Image

Examples

Embodiment 1

[0027] Place the polyester FDY fiber with a circular cross-section of 73dtex / 192f in the downstream direction of the airflow 5cm away from the plasma discharge area, and pump the plasma to a vacuum of 1×10 -2 Pa, with oxygen as the carrier gas, sulfur dioxide as the modified gas, and oxygen / sulfur dioxide as a mixed gas into the plasma, the volume content of sulfur dioxide is 10%, the gas pressure is 5Pa, and the discharge power is 100W. After 5s discharge treatment, it is obtained Modified fiber; the moisture regain of the treated material is 1.1%.

Embodiment 2

[0029] Place the polyester FDY fiber with a circular cross-section of 73dtex / 192f in the downstream direction of the airflow 60cm away from the plasma discharge area, and pump the plasma to a vacuum of 5×10 -2 Pa, with oxygen as the carrier gas, sulfur dioxide as the modified gas, and oxygen / sulfur dioxide as a mixed gas into the plasma, the volume content of sulfur dioxide is 90%, the gas pressure is 100Pa, and the discharge power is 100W. After 120s discharge treatment, it is obtained Modified fiber; the moisture regain of the treated material is 4.4%.

Embodiment 3

[0031] Place the LDPE film at a place 20cm away from the plasma discharge area downstream along the airflow direction, and pump the plasma to a vacuum of 1×10 -2Pa, with oxygen as the carrier gas, hydrogen sulfide gas as the modified gas, oxygen / hydrogen sulfide as a mixed gas into the plasma, the volume content of hydrogen sulfide is 60%, the gas pressure is 50Pa, the discharge power is 70W, after 50s The modified film was obtained after discharge treatment; the contact angle of the treated material was reduced from 105° to 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com