Continuous drying chamber for wet ceramic green

A drying chamber and wet billet technology, which is applied in the field of sanitary ceramics wet billet drying equipment, can solve the problems that the loading and unloading of transfer vehicles cannot be done too high, the space cannot be used effectively, and the heat in the drying chamber is uneven, etc., to achieve increased Space utilization, area saving, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

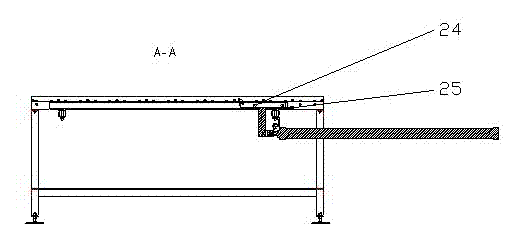

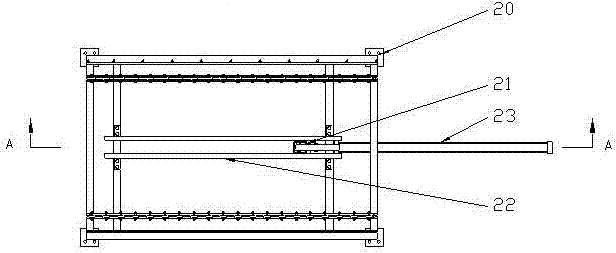

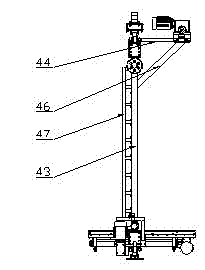

[0030] The present invention consists of a drying chamber body 1, a drying chamber inlet conveying line 2, a propulsion lifting mechanism 3, a roller shelf 4, a receiving and lifting mechanism 5, a drying chamber outlet conveying line 6, a hot air mixer 7, a heating device 8, and a moisture discharge Device 9, composed of PLC control device.

[0031] Show in the figure, overall structure of the present invention is:

[0032] Inside the drying chamber body 1, the drying chamber inlet conveying line 2, the propulsion and lifting mechanism 3, the roller shelf 4, the receiving and lifting mechanism 5, and the drying chamber outlet conveying line 6 are arranged in sequence in the form of an assembly line. Two groups of roller racks 4 are installed between the advancing mechanism 3 and the receiving lifting mechanism 5, the advancing hoist 27 is fixed by advancing the upper track 11 and the lower track 12, and can walk along the track before the roller shelf 4, and the receiving hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com