Analytical method for content of short fibers in pole plate lead paste of lead-acid battery

A lead-acid battery and analysis method technology, applied in the direction of removing certain component weighing, etc., can solve the problems of no data support, unscientific and other problems, and achieve the effect of simple and convenient use of tools, fewer types, and accurate and reliable analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: according to the following concrete steps analysis and the short fiber quality of the lead plaster that plastering completes:

[0012] Take the finished lead paste in three times and seal it with a PE bag; knead the lead paste into flakes by hand, take out the block lead paste, weigh 40g (accurate to 0.001g), put it into a 500mL beaker, and add the mass concentration 300mL of 12% nitric acid solution, boiled, stirred until there are no obvious lumps, so that the lead sulfate is dispersed, slowly sieved in the center of a 200-mesh sieve, so that the short fibers are accumulated in the center of the sieve, washed with water until the short fibers are white and free of impurities , Dry at 110°C for 30 minutes to obtain short fibers; calculate the mass percentage of short fibers in the lead paste by analyzing the short fiber content of the balance. The results are shown in Table 1.

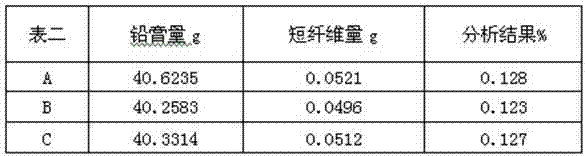

[0013]

[0014] When the short fiber is added as an auxiliary material, t...

Embodiment 2

[0015] Embodiment 2: according to the following specific steps, analyze the lead paste that has been converted into a dry positive plate:

[0016] Take the lead plaster that has been turned into a dried positive plate in three times, and seal it with a PE bag; take out the block lead plaster, weigh 40g (accurate to 0.001g), put it into a 500mL beaker, add 200mL of nitric acid and hydrogen peroxide mixed solution, stir and dissolve until nothing Obvious pimples, the solution is translucent and turbid, slowly sieved at the center of a 200-mesh sieve, so that the short fibers are accumulated in the center of the sieve, washed with water until the short fibers are white and free of impurities, and dried at 110°C for 30 minutes to obtain short fibers; by Analyze the short fiber content of the balance scale, and calculate the mass percentage of the short fiber in the lead paste. The results are shown in Table 2.

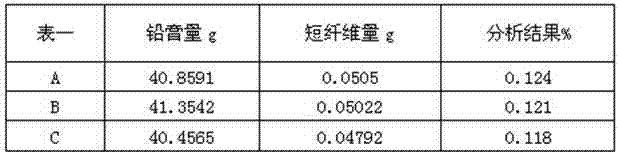

[0017]

[0018] The positive lead paste is cured, dried, and chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com