Printed circuit board and manufacturing method thereof

A technology for printed circuit boards and dielectric substrates, applied in the fields of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of increased signal transmission loss, loss of green oil coating layer, and PCB pressing warpage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

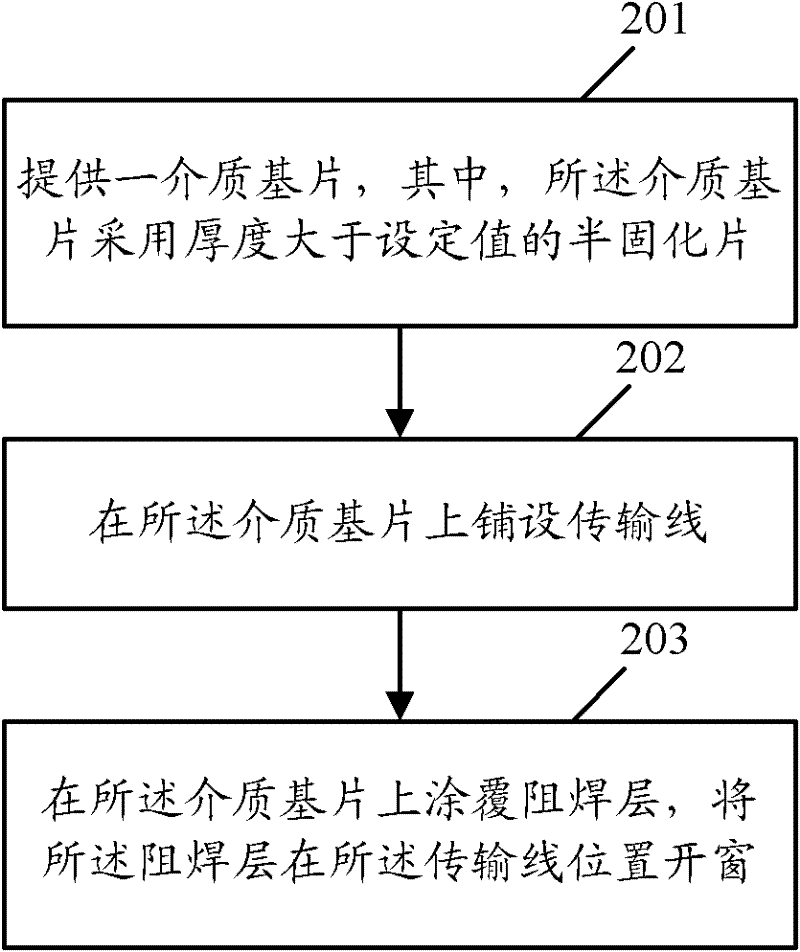

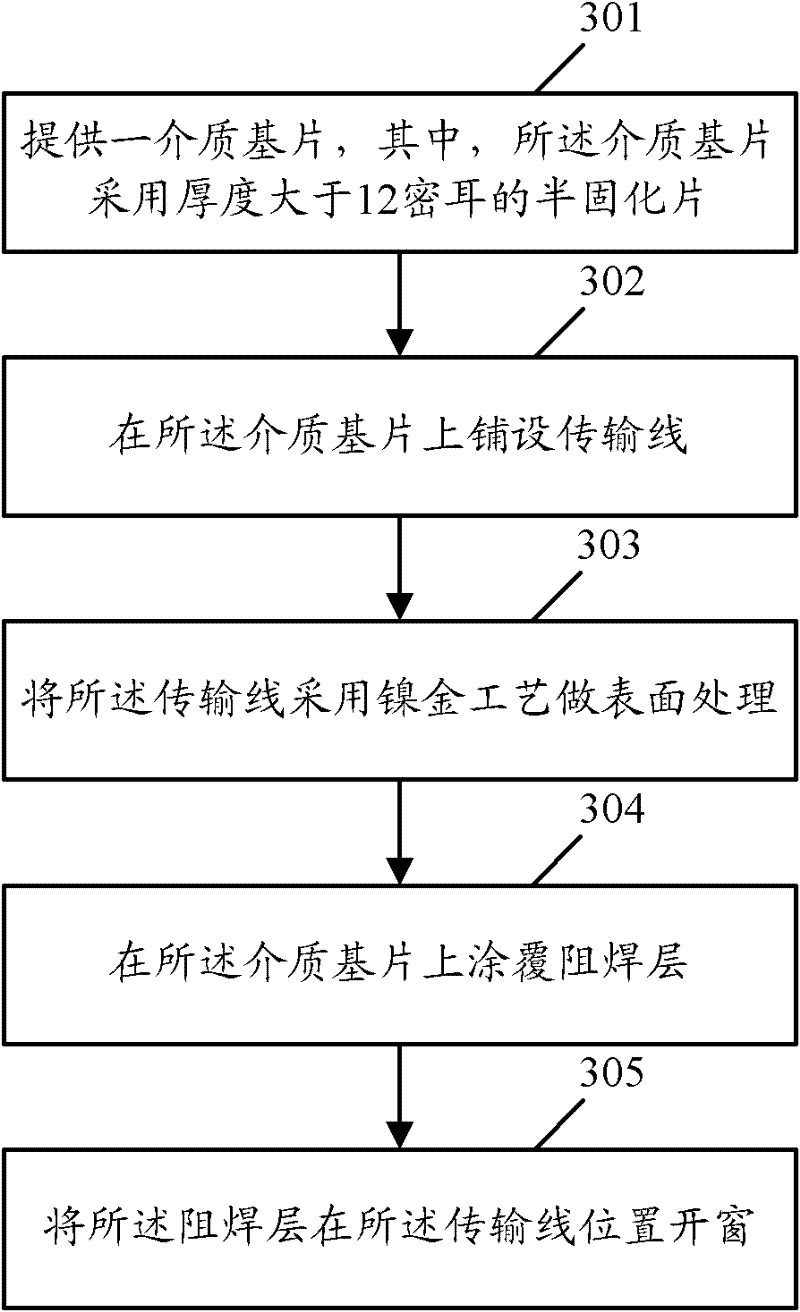

[0023] In order to reduce signal transmission loss and reduce production costs, the printed circuit board provided by the embodiment of the present invention includes: a dielectric substrate, using a prepreg with a thickness greater than a set value; a transmission line, formed on the dielectric substrate; A solder resist layer where the transmission line is windowed is formed on the dielectric substrate.

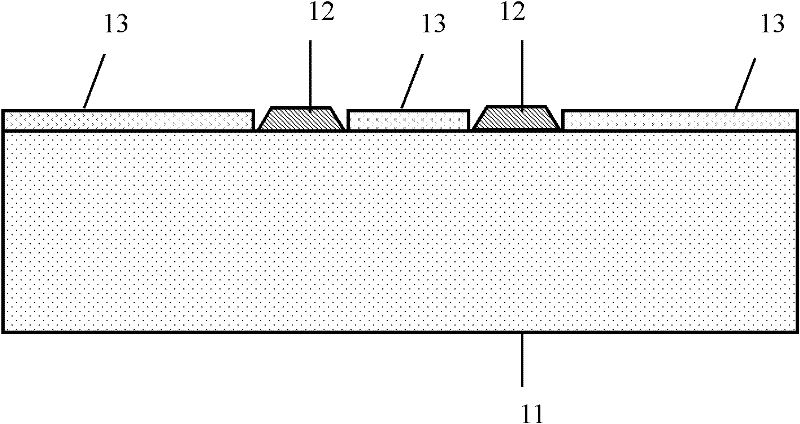

[0024] figure 1 It is a schematic structural diagram of a printed circuit board according to an embodiment of the present invention. Such as figure 1 As shown, the printed circuit board of the embodiment of the present invention includes:

[0025] The dielectric substrate 11 adopts a prepreg whose thickness is greater than a set value;

[0026] a transmission line 12 formed on the dielectric substrate 11;

[0027] A solder resist layer 13 with a window opened at the position of the transmission line 12 is formed on the dielectric substrate 11 .

[0028] The dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com