Nozzle plate having nozzles disposed convexly and the use of the same

A technology of nozzle plates and nozzles, which is applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems that do not allow the improvement of production capacity and operation reliability, and achieve consistent discharge speed, reduced discharge speed, and uniform pressure distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

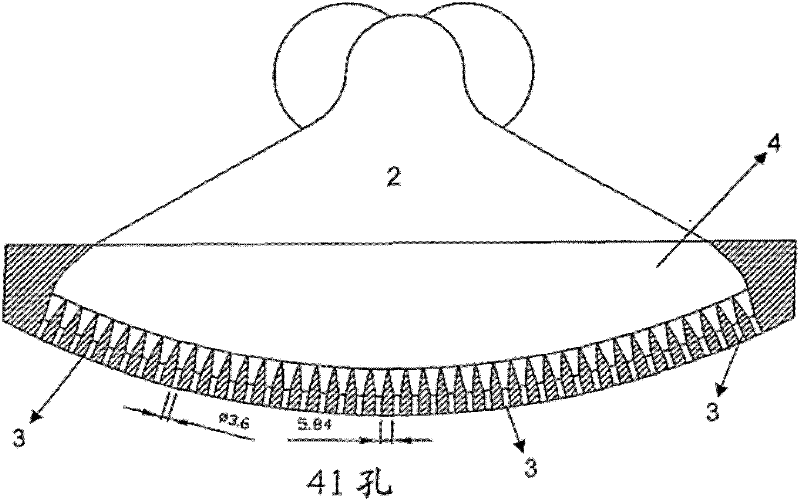

[0054] A concave and convex nozzle plate is installed, including 41 nozzles in a single row, and the productivity of the preceding twin-screw extruder is 1700kg / h. The discharge speed of the wire granulator following the wire cooling bath and the wire drying section was 120 m / min.

[0055] Result description:

[0056] The discharged wires have almost the same diameter of 3.4-3.8 mm due to a more uniform pressure distribution of the melt in the concave nozzle plate cavity.

[0057] The wire pelletizer was run at 120 m / min, ie 85% of its maximum discharge speed.

[0058] The running behavior of the wire is calm and uniform without wire breakage.

example 2

[0060] The nozzle plate of Example 1 was again installed, comprising a single row of 41 nozzles. The productivity of the preceding twin-screw extruder is 2000kg / h. The discharge speed of the wire granulator following the wire cooling bath and the wire drying section was 140 m / min.

[0061] Result description:

[0062] The emerging wires again have almost the same diameter of 3.4-3.8 mm due to a more uniform pressure distribution of the melt in the concave nozzle plate cavity.

[0063] Due to the higher production capacity, the wire pelletizer is now operating as in comparative example 1 at 140 m / min, ie 100% of its maximum discharge speed.

[0064] The running behavior of the wire is calm and uniform.

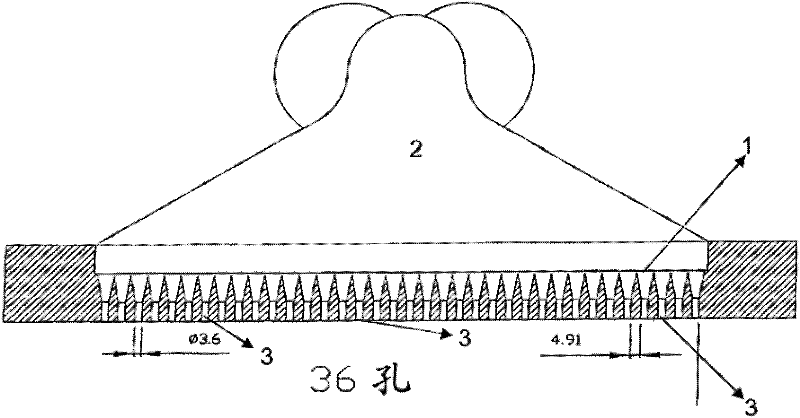

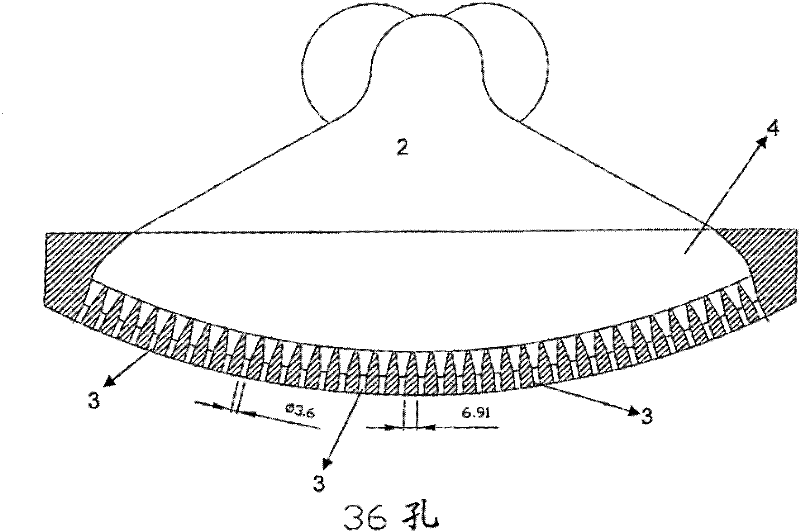

[0065] Compared to a single-row flat nozzle plate with 36 holes, the number of nozzles can also be increased to 45 holes by using a concave-convex design, until the discharged wires are likewise at a distance of about 5 mm from each other (see comparative example 1). In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com