Electron beam welding method for variable-section gas turbine casing

An electron beam welding and gas turbine technology, which is applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems such as the inability to meet the cylinder body and the variable-section horizontal flange, and achieve convenient welding methods and welding seam forming. The effect of good quality, improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

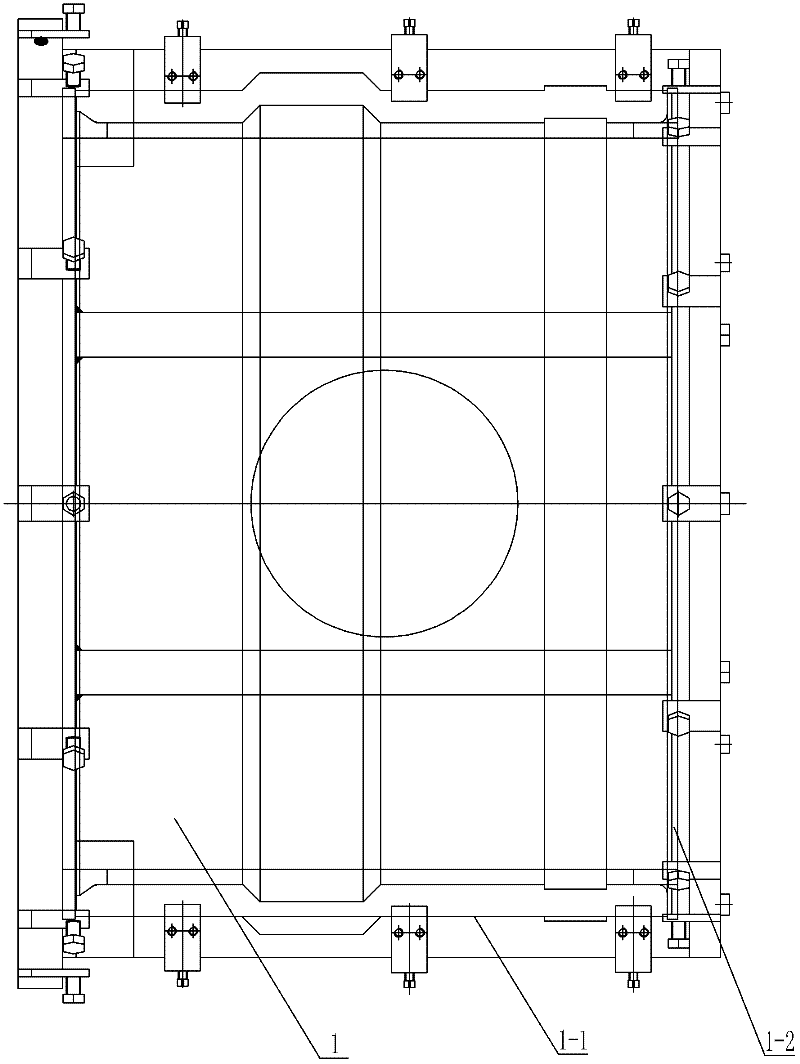

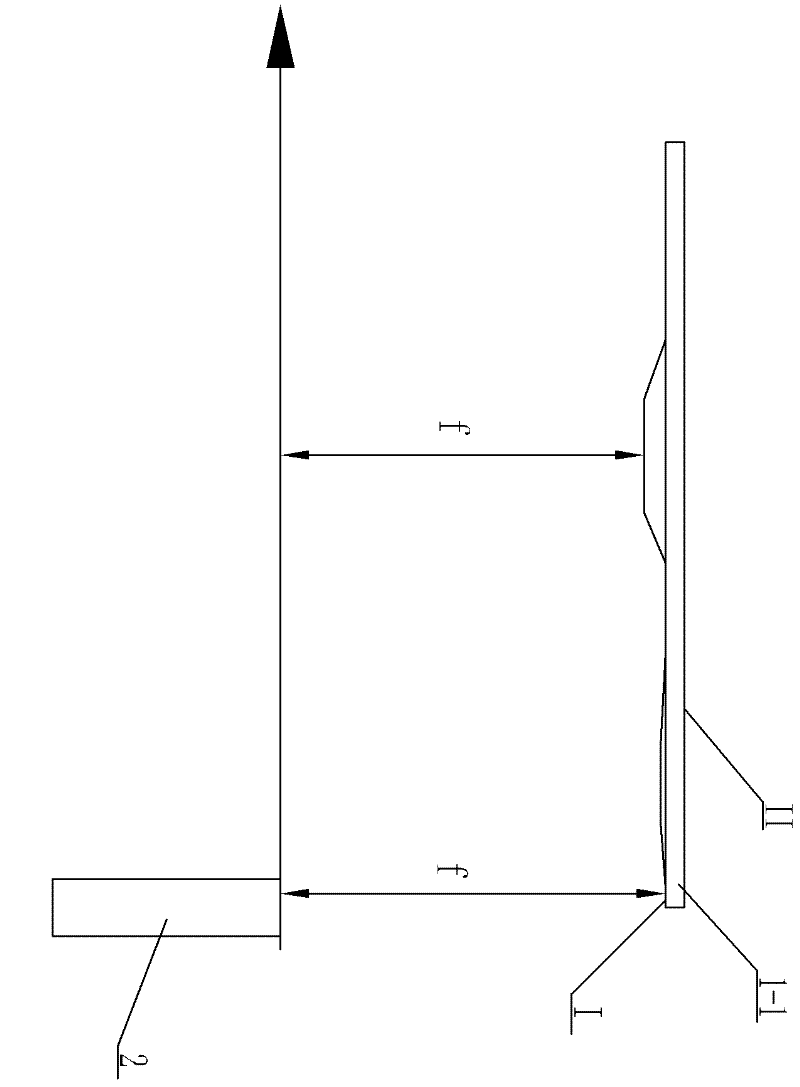

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 2 Illustrate embodiment, the electron beam welding method of a kind of variable section structure gas turbine case of present embodiment is to realize according to the following steps: one, select electron beam welding machine; The surface of the workbench in the vacuum chamber of the welding machine; the casing 1 is composed of two variable-section horizontal flanges 1-1 and a cylinder body 1-2; 3. Put the casing and the tooling fixture cleaned in step 2 into the welding machine. On the workbench in the vacuum chamber of the machine, assemble the casing 1 on the tooling fixture, adjust the parallelism and verticality of the two variable-section horizontal flanges 1-1 and the cylinder body 1-2; adjust the electron gun 2 and the variable-section horizontal method The distance between the flanges 1-1, the two variable cross-section horizontal flanges 1-1 and the cylinder 1-2 are positioned and spot welded, 4. El...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 The embodiment is described. The difference between this embodiment and the first embodiment is that the distance f between the electron gun 2 and the lower surface I of the variable cross-section horizontal flange 1-1 in step 4 is 200mm-350mm. Others are the same as in the first embodiment.

[0009] The cleaning of each surface of the casing, the surface of the fixture and the surface of the workbench in the vacuum chamber of the welding machine described in this embodiment is mainly to remove the rust, scale, paint, oil, emulsion, etc. on the surfaces of the parts to be welded, focusing on the horizontal method Clean the butt surface of the flange and the cylinder to be welded and the surrounding area of 20mm, and at the same time clean the dust, oil and other dirt on the surface of the workbench and each fixture.

[0010] The distance between the electron gun 2 and the lower surface I of the variable-section ...

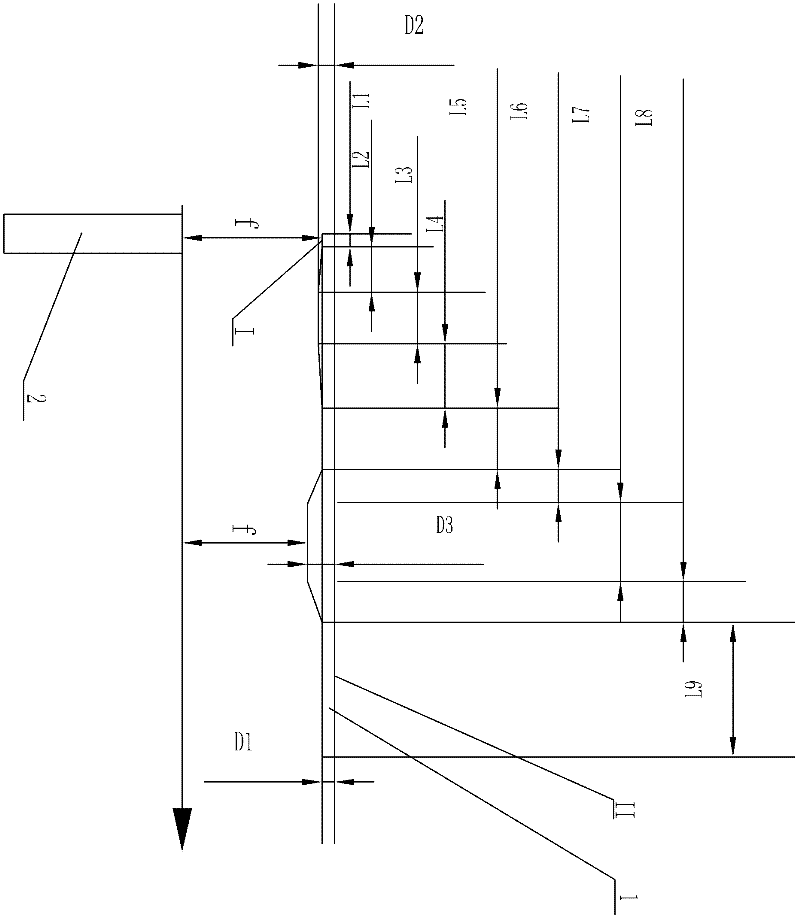

Embodiment

[0011] Example: such as image 3 As shown, in this embodiment, the selected voltage is 60KV, and the vacuum chamber volume of 60KW is 49M 3 Electron beam welding machine with a thickness of 16.7mm ~ 36.3mm and a length of 692mm for welding with a variable cross-section horizontal flange and the cylinder, and the vacuum degree in the vacuum chamber reaches 5.5×10 -2 Pa~8.8×10 -2 Pa, the vacuum degree of the electron gun of the welding machine is 8.0×10 -3 Pa~9.6×10 -3 Under the condition of Pa, the variable cross-section flange is divided into 9 sections for welding. The first section is electron beam welding with thickness D1 of 16.7mm and displacement L1 of 17mm; the second section is of thickness D1 from 16.7mm to D2. 21.7mm, displacement L2 is 60mm variable thickness electron beam welding; the third section is thickness D2 is 21.7mm, displacement L3 is 68.5mm equal thickness electron beam welding; the fourth section is thickness D2 is 21.7 to D1 is 16.7mm, displacement L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com