Wastewater treatment system for acrylic acid industry

A technology for industrial wastewater and treatment systems, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of increased treatment costs, large one-time investment, and secondary Pollution and other problems, to achieve the effect of improving biodegradability, low investment cost, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

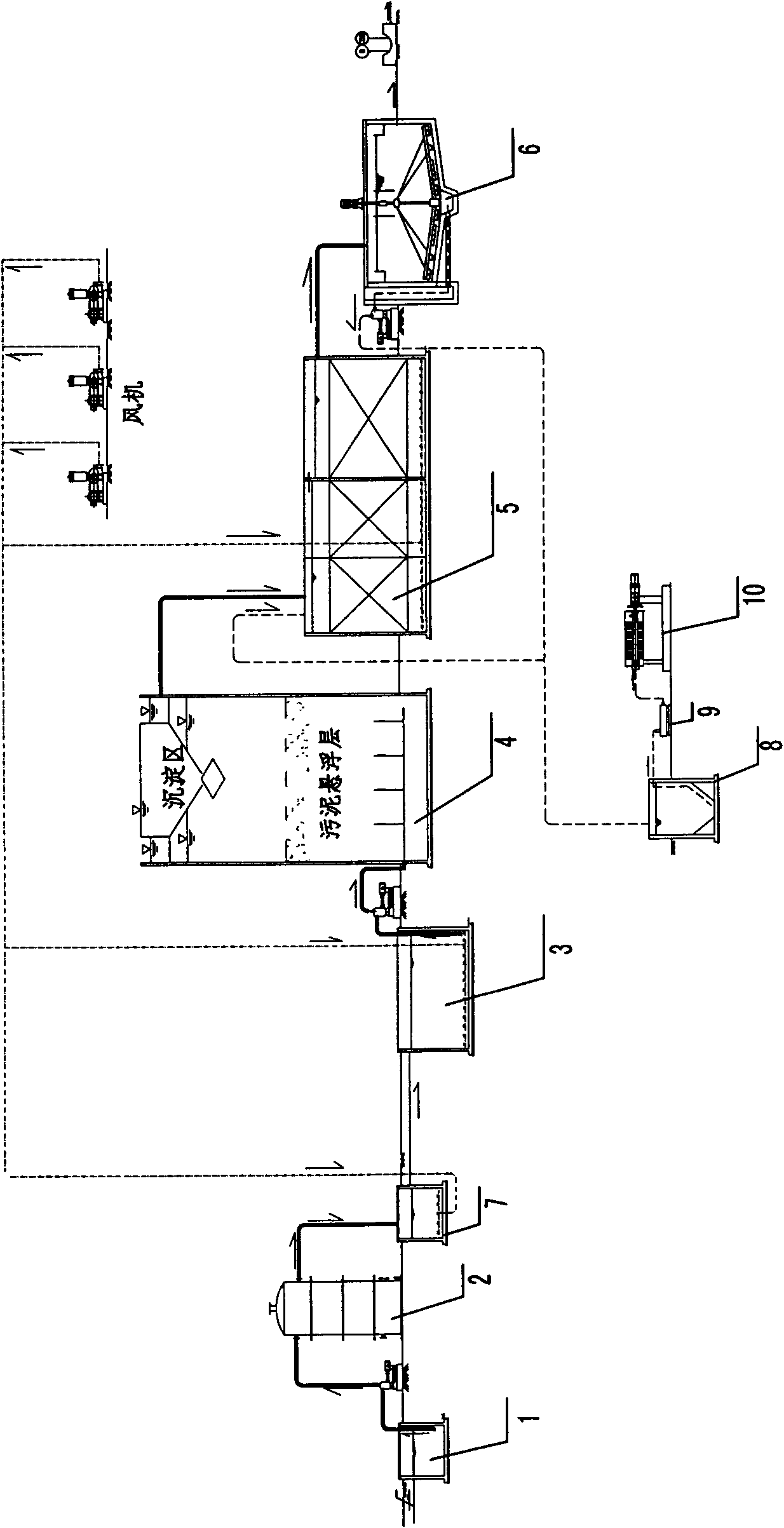

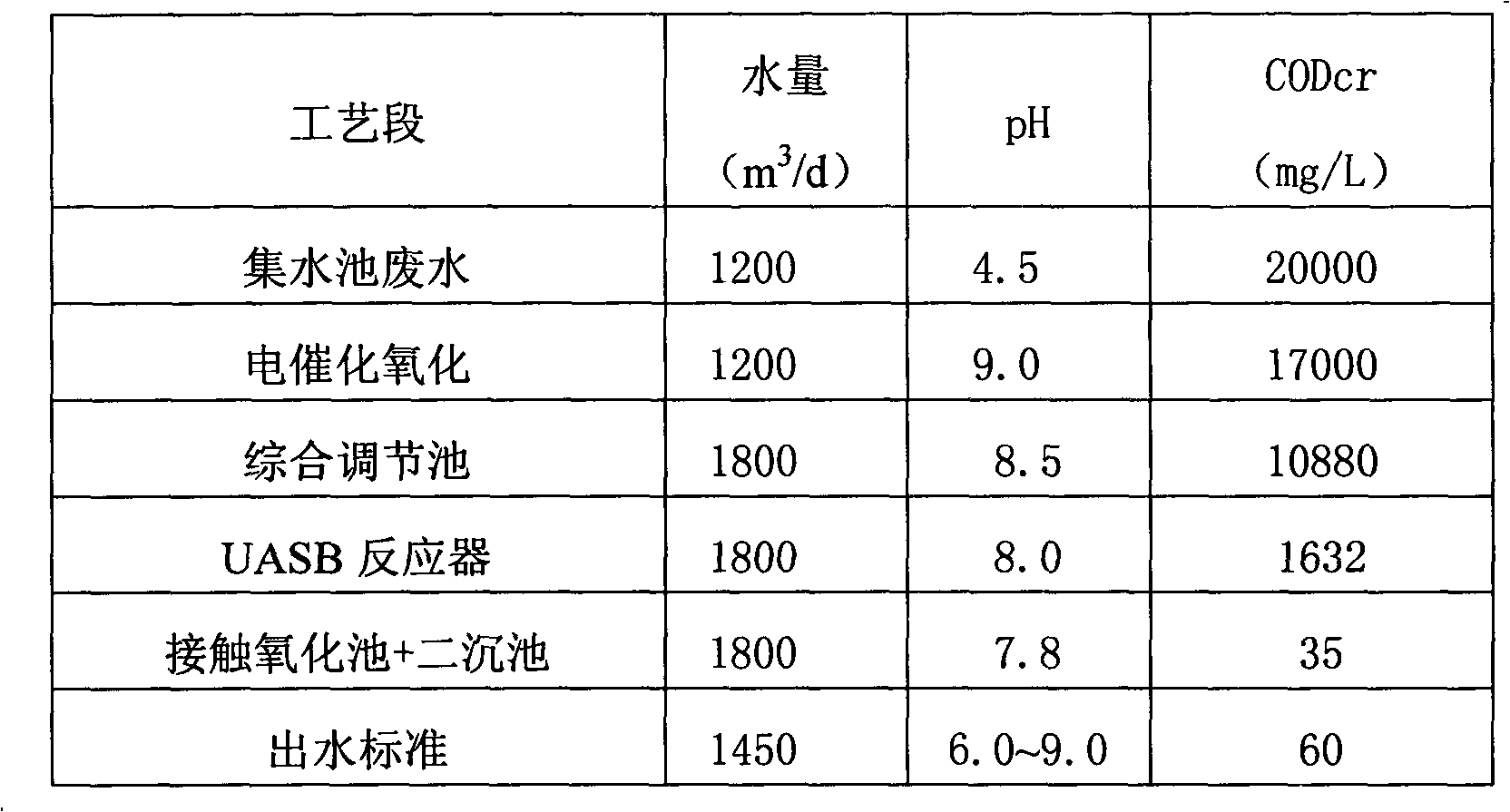

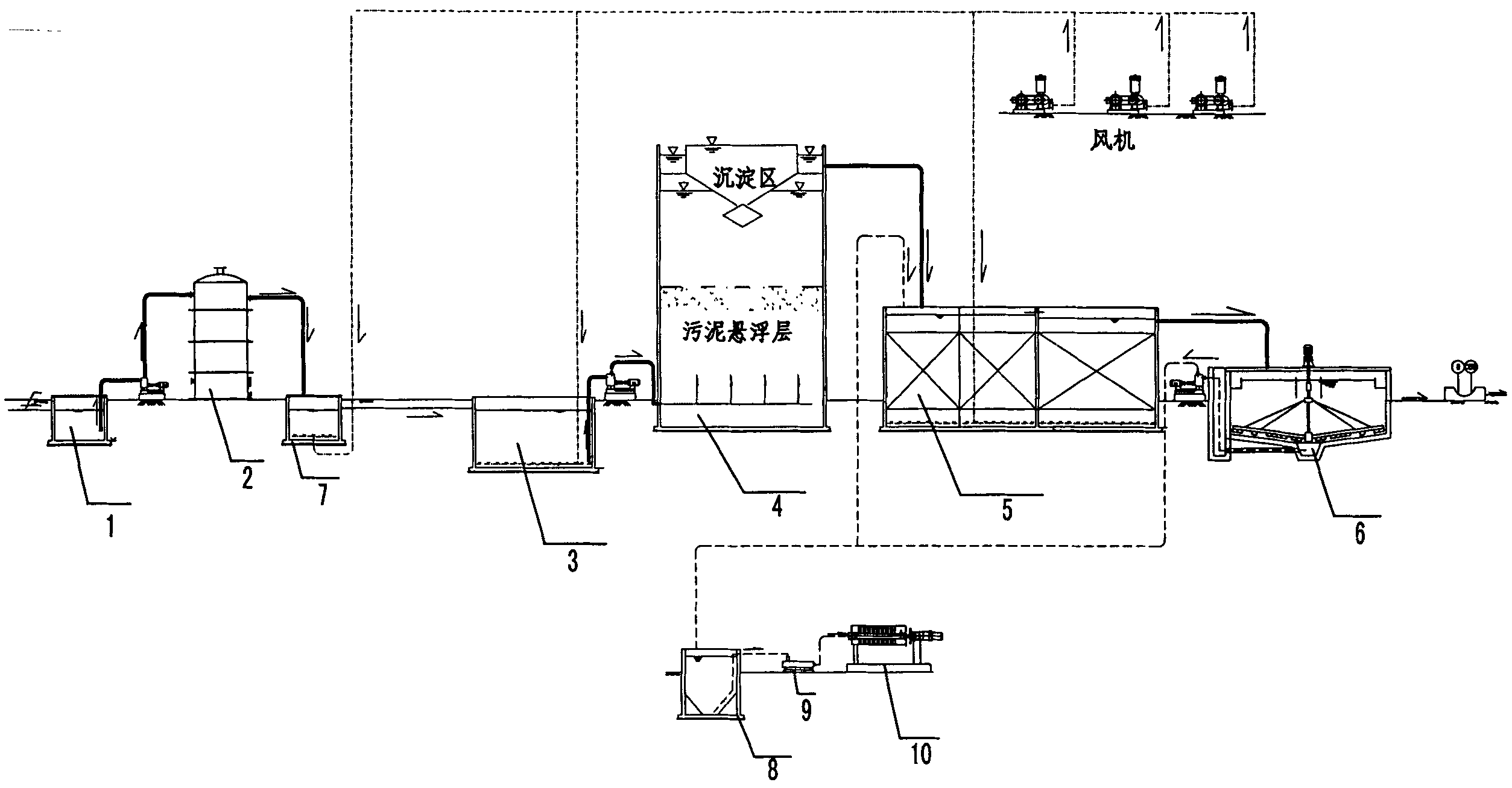

[0015] A wastewater treatment system for the acrylic acid industry, the system includes a water collection tank 1, an electrocatalytic oxidation device 2, a comprehensive adjustment tank 3, a UASB reactor 4, a contact oxidation tank 5 and a secondary sedimentation tank 6, the water outlet of the water collection tank 1 and the electrocatalytic The water inlet of the oxidation device 2 is connected, the water outlet of the electrocatalytic oxidation device is connected with the water inlet of the comprehensive regulating tank 3, the water outlet of the comprehensive regulating tank 3 is connected with the water inlet of the UASB reactor 4, and the water outlet of the UASB reactor 4 is connected with the water inlet of the UASB reactor 4. The water inlet of the contact oxidation tank 5 is connected, the water outlet of the contact oxidation tank 5 is connected with the water inlet of the secondary sedimentation tank 6, and the water outlet of the secondary sedimentation tank 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com