Wiring harness protective plate and manufacturing method thereof

A manufacturing method and wire harness technology, applied in the field of wire harness shields and its manufacturing, can solve the problems of easy whitening, low strength, poor toughness, etc., and achieve the effects of reducing production costs, stabilizing product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

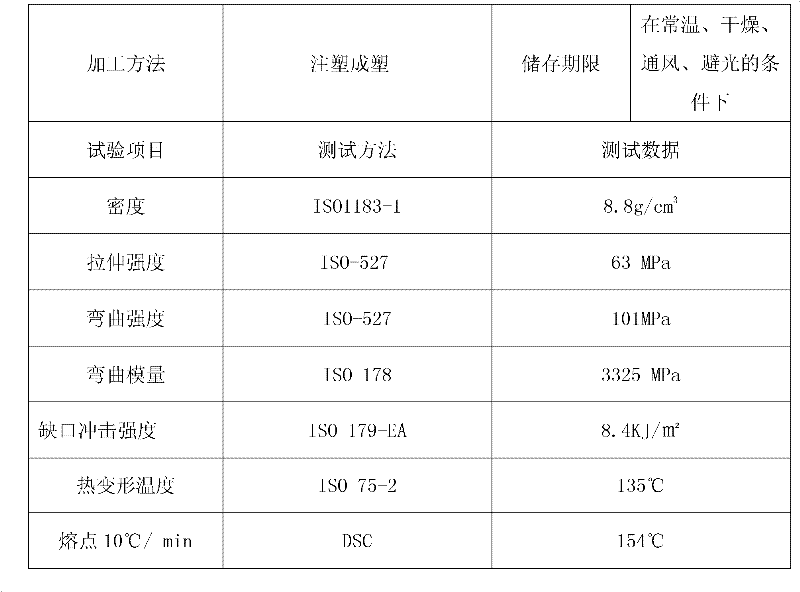

Image

Examples

Embodiment 1

[0017] Example 1: wire harness guard plate, its composition materials include composition A and composition B, the composition A: 75 parts of polypropylene, 15 parts of elastomer SBS, 15 parts of epoxy resin, 5 parts of light calcium, straw 5 parts of ash and 5 parts of diatomaceous earth; Composition B: 45 parts of glass fiber, 5 parts of chlorinated polyethylene, 5 parts of polypropylene resin, 3 parts of silane coupling agent, 5 parts of tetrafluoroethylene, and 5 parts of polyethylene wax , 3 parts of zinc oxide, 40103 parts of anti-aging agent and 5 parts of attapulgite.

[0018] A method for manufacturing a wire harness guard, comprising the following steps:

[0019] (1) Weigh each raw material according to the weight part of composition A raw material, carry out drying treatment, drying temperature is 80-100 ℃, drying time is 1-2 hour, mix evenly, put into dryer, at 140-160 ℃ Dry for 24-28 hours;

[0020] (2) Weigh each raw material according to the weight part of com...

Embodiment 2

[0027] Example 2: wire harness guard plate, its composition materials include composition A and composition B, the composition A: 85 parts of polypropylene, 25 parts of elastomer SBS, 25 parts of epoxy resin, 10 parts of light calcium, straw 10 parts of ash and 10 parts of diatomaceous earth; Composition B: 55 parts of glass fiber, 10 parts of chlorinated polyethylene, 10 parts of polypropylene resin, 5 parts of silane coupling agent, 15 parts of tetrafluoroethylene, 10 parts of polyethylene wax , 5 parts of zinc oxide, 40105 parts of anti-aging agent and 10 parts of attapulgite.

[0028] A method for manufacturing a wire harness guard, comprising the following steps:

[0029] (1) Weigh each raw material according to the weight part of composition A raw material, carry out drying treatment, drying temperature is 80-100 ℃, drying time is 1-2 hour, mix evenly, put into dryer, at 140-160 ℃ Dry for 24-28 hours;

[0030] (2) Weigh each raw material according to the weight part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com