Method for growing GaN-based LED (Light Emitting Diode) on patterned substrate

A technology of LED epitaxial wafers and graphic substrates, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor antistatic ability and large leakage current of epitaxial wafers, so as to improve the light extraction effect and prolong the service life , The effect of reducing the leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Add O to the reaction chamber 2 , its content is 10ppm, where O 2 Added to the reaction chamber in a mixed form with nitrogen, and O in the mixed gas 2 The content is 25%;

[0060] 2. High temperature treatment: In the MOCVD reaction chamber, high-purity H 2 , reduce the pressure of the reaction chamber to 150 mbar, heat the patterned substrate to 1100 ° C, and treat at high temperature for 15 minutes;

[0061] 3. Nitriding treatment: cool down to 700°C, and pass NH into the reaction chamber 3 The flow rate is 10 standard liters / minute, and the time is 100 seconds, and the pattern substrate is nitrided;

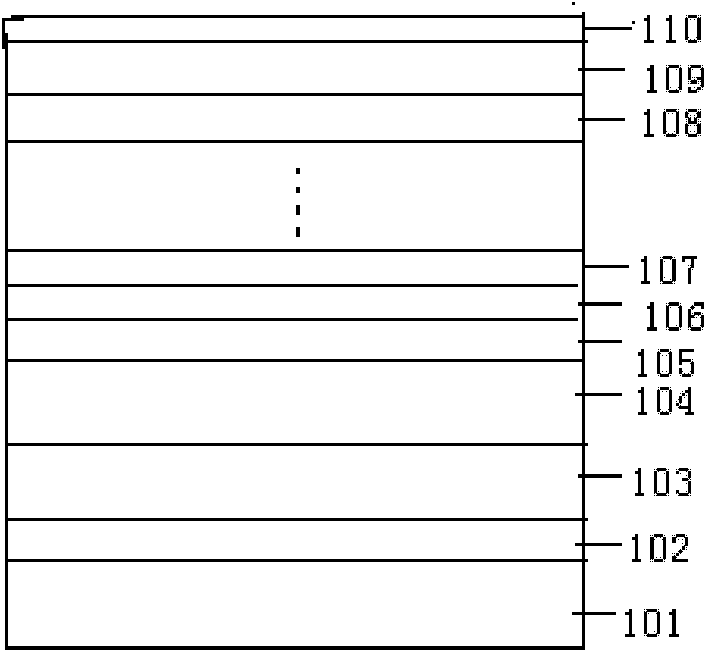

[0062] 4. Growth nucleation layer (such as figure 1 middle layer 102): reduce the temperature to 500°C in H 2 Under the atmosphere, a low-temperature buffer layer GaN with a thickness of 30 nanometers (such as figure 1 Middle 102nd Floor), NH 3 The flow rate is 10 standard liters / minute, and the flow rate of TMGa is 3×10 -4 mol / min, H 2 The flow rate is 80...

Embodiment 2

[0072] 1. Add O to the reaction chamber 2 and Cl 2 , its content is 5000ppm, where O 2 and Cl 2 Added to the reaction chamber in a mixed form with nitrogen, and O in the mixed gas 2 and Cl 2 The content is 40%;

[0073] 2. High temperature treatment: In the MOCVD reaction chamber, high-purity H 2 , reduce the pressure of the reaction chamber to 150 mbar, heat the patterned substrate to 1100 ° C, and treat at high temperature for 15 minutes;

[0074] 3. Nitriding treatment: cool down to 700°C, and pass NH into the reaction chamber 3 The flow rate is 10 standard liters / minute, and the time is 100 seconds, and the pattern substrate is nitrided;

[0075] 4. Growth nucleation layer (such as figure 1 middle layer 102): reduce the temperature to 500°C in H 2 Under the atmosphere, a low-temperature buffer layer GaN with a thickness of 30 nanometers (such as figure 1 Middle 102nd Floor), NH 3 The flow rate is 10 standard liters / minute, and the flow rate of TMGa is 3×10 -4 m...

Embodiment 3

[0078] 1. Add CO into the reaction chamber, the content of which is 10000ppm, wherein CO and nitrogen are added into the reaction chamber in a mixed form, and the content of CO in the mixed gas is 50%;

[0079] 2. High temperature treatment: In the MOCVD reaction chamber, high-purity H 2 , reduce the pressure of the reaction chamber to 150 mbar, heat the patterned substrate to 1100 ° C, and treat at high temperature for 15 minutes;

[0080] 3. Nitriding treatment: cool down to 700°C, and pass NH into the reaction chamber 3 The flow rate is 10 standard liters / minute, and the time is 100 seconds, and the pattern substrate is nitrided;

[0081] 4. Growth nucleation layer (such as figure 1 middle layer 102): reduce the temperature to 500°C in H 2 Under the atmosphere, a low-temperature buffer layer GaN with a thickness of 30 nanometers (such as figure 1 Middle 102nd Floor), NH 3 The flow rate is 10 standard liters / minute, and the flow rate of TMGa is 3×10 -4 mol / min, H 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com