Organic light-emitting device and preparation method thereof

An electroluminescent device and luminescent technology, applied in the field of OLED devices, can solve problems such as inability to completely eliminate short-circuit points, lower device efficiency, and OLED screen failure, so as to avoid material decomposition and breakdown problems, prevent leakage current and device Effect of failure, elimination of plasma mode loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

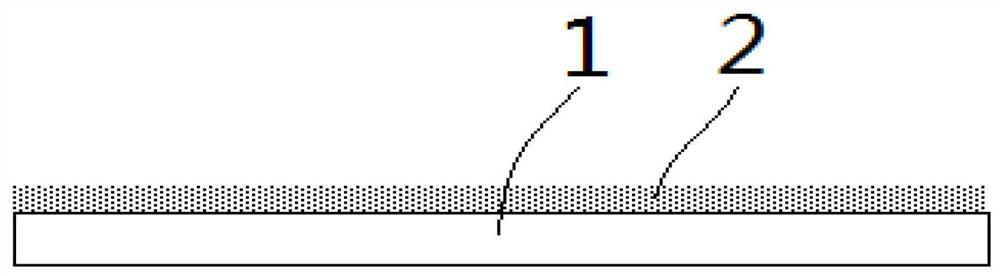

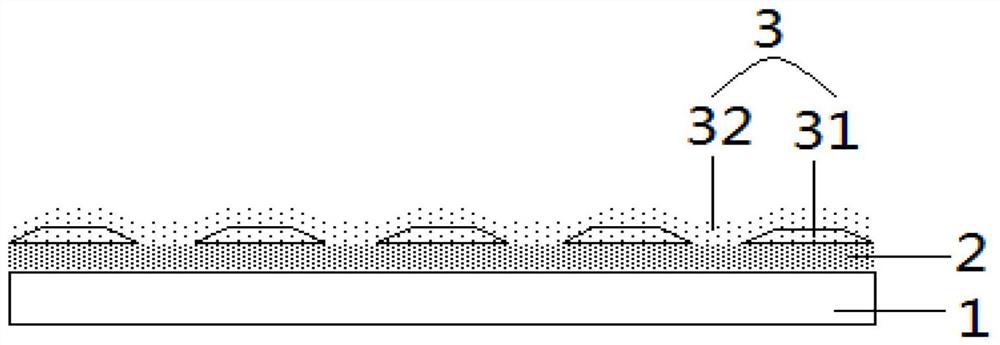

[0044] like Figure 1-5 As shown, the present invention provides an organic electroluminescent device, comprising a substrate 1, a transparent electrode layer 2, an organic functional layer 4 and a metal cathode layer 6 disposed on the transparent electrode layer 2, the transparent electrode layer 2 and the organic functional layer The undulating transparent resistance layer 3 is arranged between the 4, and the surface of the organic functional layer 4 is arranged on the undulating transparent resistance layer 3 in an undulating shape. By designing the transparent resistance layer on the transparent electrode layer, the surface of the transparent resistance layer is undulating, and the accompanying fluctuations of the organic functional layer 4 and the reflective metal cathode layer 6 eliminate the plasma on the flat surface of the metal cathode layer 6 to a certain extent. Mode loss; at the same time, the existence of the transparent resistance layer eliminates the short circ...

Embodiment 2

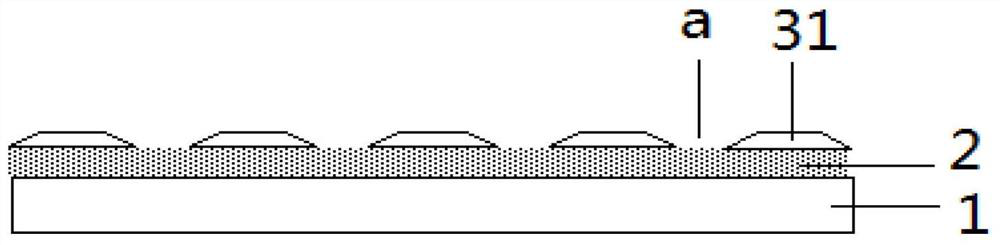

[0062] like Figure 2-5 As shown, the present invention also provides a short-circuit proof light-emitting device with a light extraction structure, including a substrate 1, a transparent electrode layer 2, an organic functional layer 4 and a metal cathode layer 6 disposed on the transparent electrode layer 2, and the transparent electrode layer An undulating transparent resistive layer 3 is arranged between 2 and the organic functional layer 4, and the surface of the organic functional layer 4 is undulatingly arranged on the undulating transparent resistive layer 3. like image 3 As shown, a grid or porous structure a is formed on the surface of the transparent electrode layer 2. The grid or porous structure a in the figure is a circular hole with the same or different upper and lower diameters, and its maximum aperture is 5 μm-500 μm. For polygonal holes such as triangular holes and square holes with the same or different calibers, the longest distance between two points co...

Embodiment 3

[0086] On the basis of Embodiment 2, this embodiment etches the grid or porous structure formed on the surface of the transparent electrode 2, and etches such as Figure 2-5 The indicated taper angles (inclination angles) β are 10°, 20°, 30°, 40°, 50°, 60°, 70°, and 80° respectively. The following table shows the performance comparison of the corresponding angles.

[0087]

[0088]

[0089] It can be seen from the comparison that different taper angles β have different light extraction efficiencies. When the taper angle β is 30°-60°, the device in the above table generates the smallest passing current and the highest brightness. This is because the taper angle β is greater than 60° When the taper angle β is less than 30°, the direction of the light and the morphology of the cathode cannot be effectively changed due to the inconspicuous undulation. Of course, the relief layer formed in the present invention can also be caused by the relief of the metal layer grid or other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com