Pump/motor-based parallel-series hybrid hydraulic excavator driving system

A hydraulic excavator and drive system technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as complex structure, high cost, and complex energy flow, and achieve improved Reliable operation, improved reliability, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

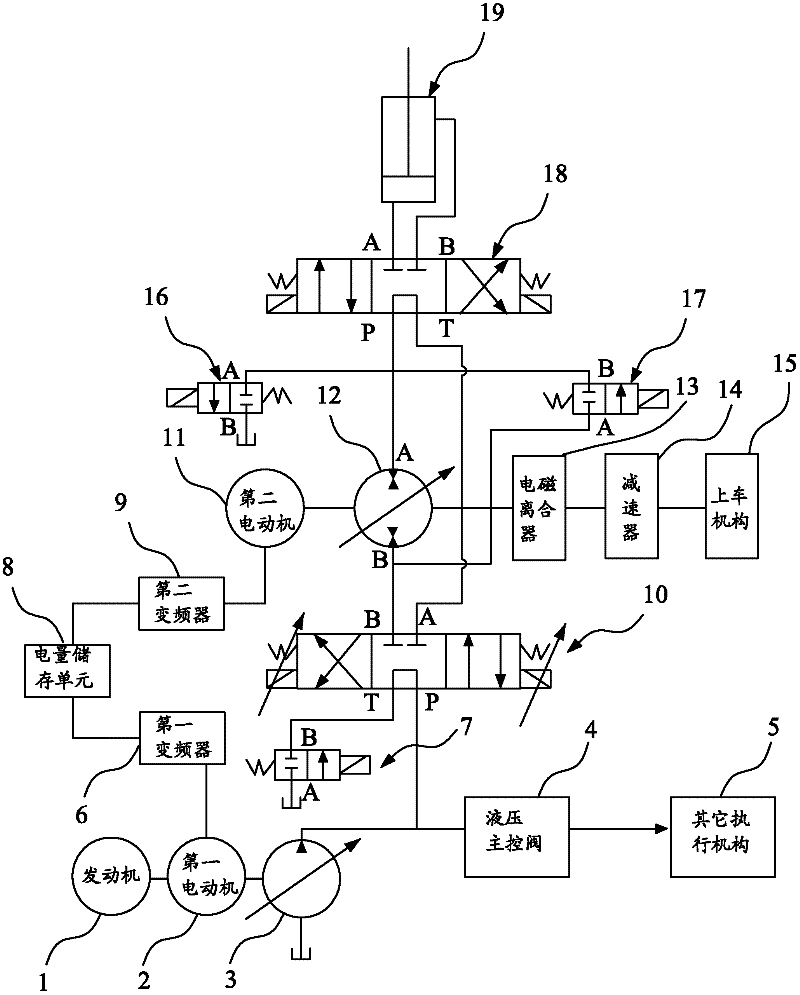

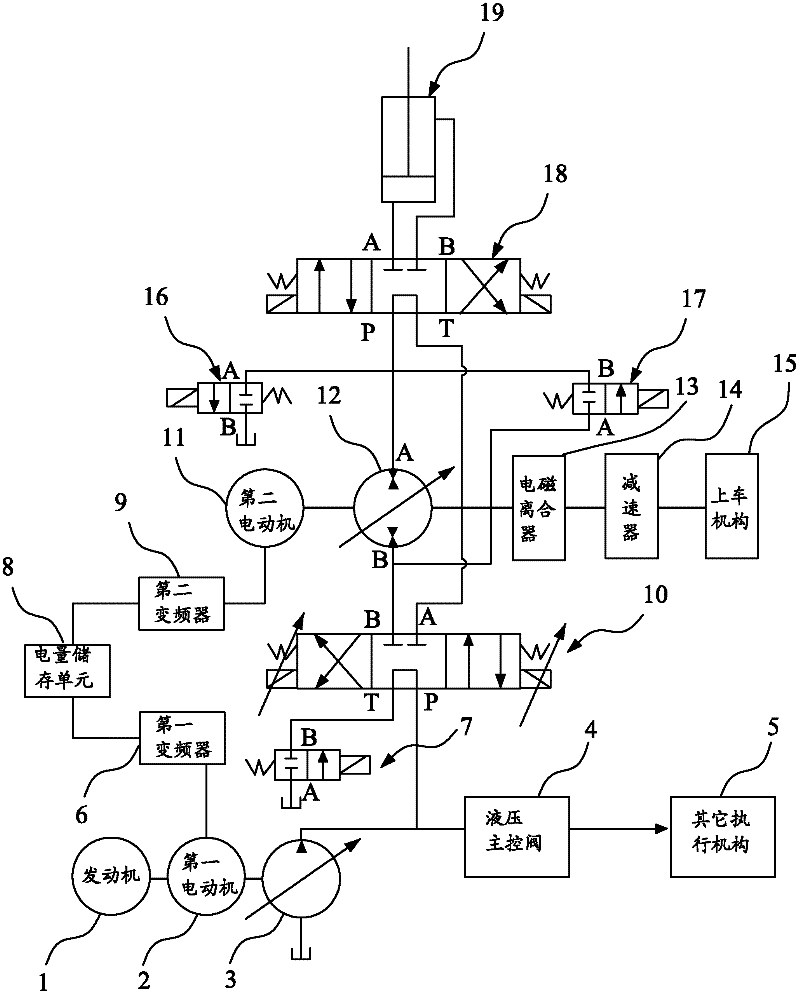

[0034] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes an engine 1, a variable pump 3, a hydraulic main control valve 4, a group of bucket cylinders, arm cylinders and travel hydraulic motors Other hydraulic actuators composed of 5, a pump / motor 12, a proportional directional valve 10, two motors 2, 11, two frequency converters 6, 9, a set of power storage unit 8, four electromagnetic reversing valves 7, 16, 17,18, an electromagnetic clutch 13, a speed reducer 14 and a boom drive oil cylinder 19.

[0035] The interconnection of each component is as follows:

[0036] The engine 1, the first electric motor 2 and the variable displacement pump 3 are connected by coaxial mechanical transmission to form a parallel hybrid power system;

[0037] The second electric motor 11 and the pump / motor 12 are connected with the coaxial mechanical transmission, and together with the coaxially connected eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com