Indirectly driven traction type pumping unit

A pumping unit and traction technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of insufficient loss-of-load protection, limited application environment, limited traction force, etc., to increase the service life and Safety factor, increased safety, and the effect of balanced force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

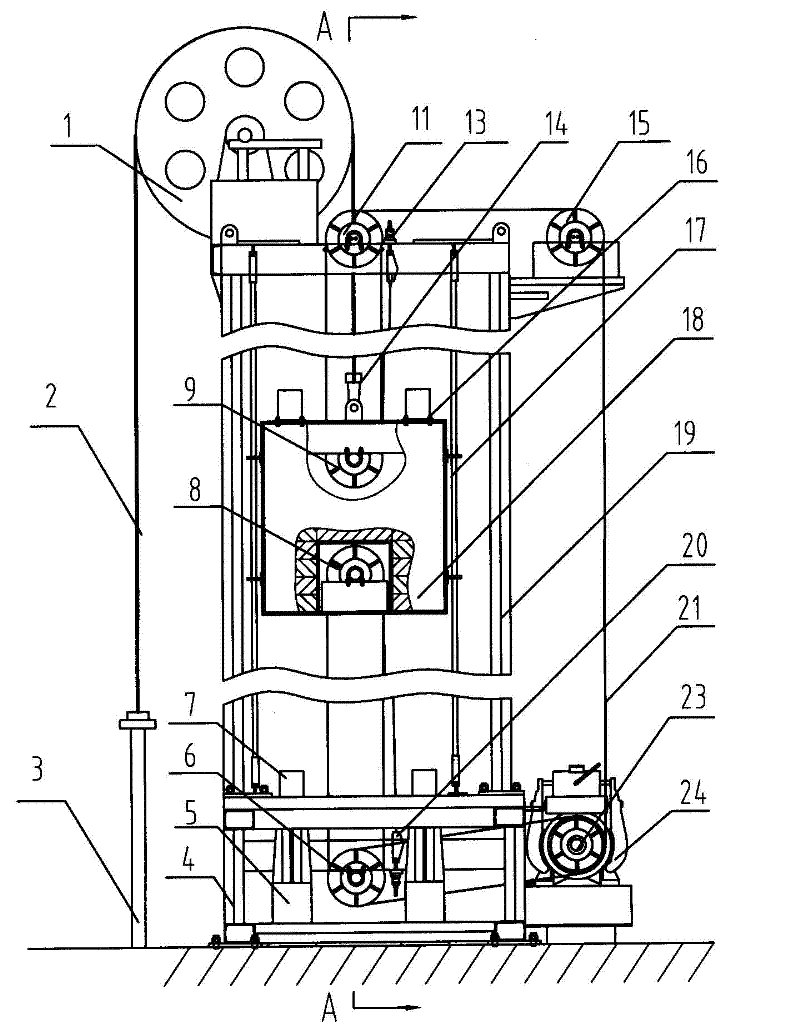

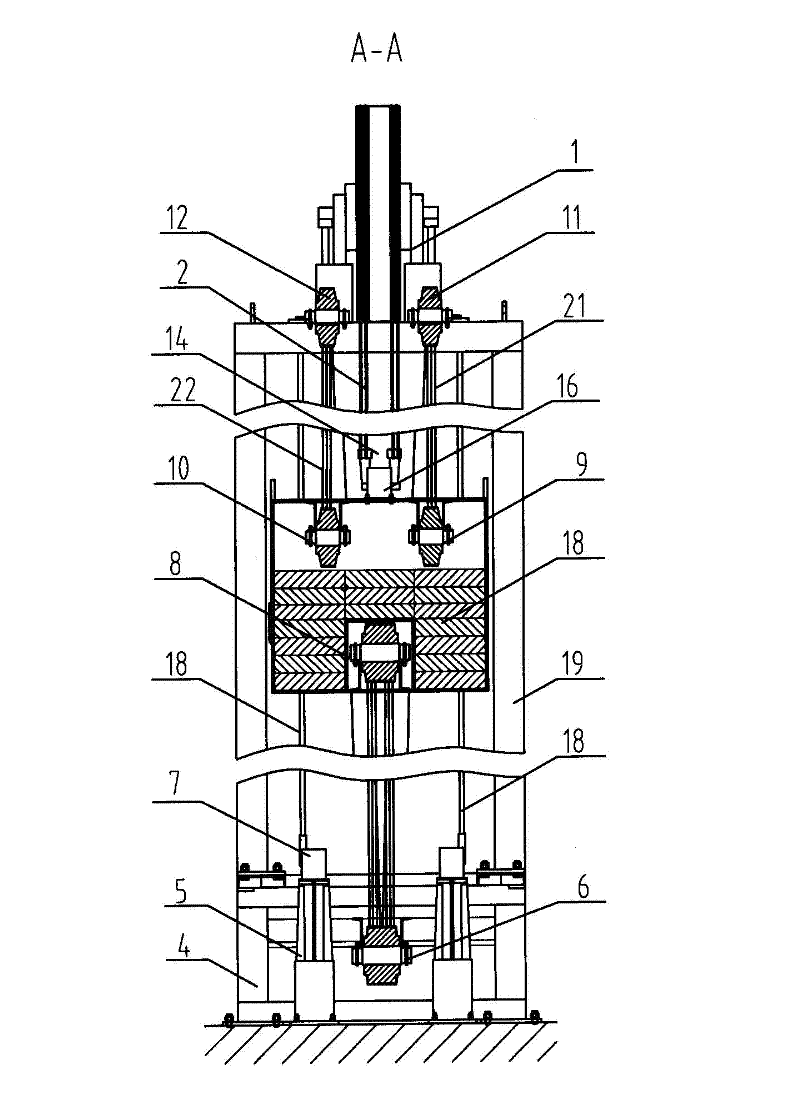

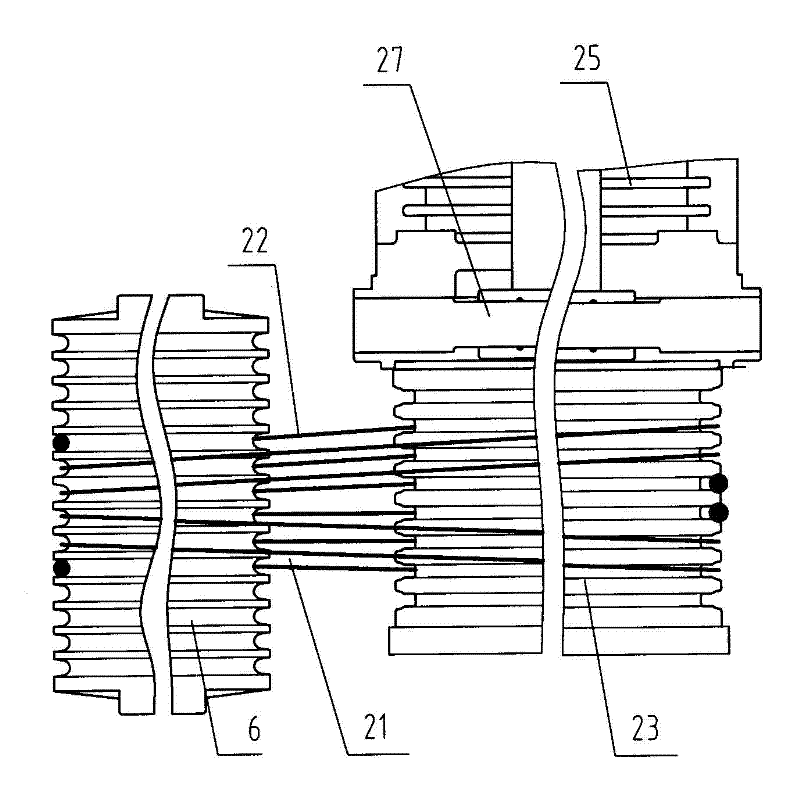

[0028] according to Figure 1~5 The specific structure of the present invention will be described in detail. The indirect drive traction pumping unit includes a frame 19, a frame 4, a suspension device arranged on the frame 19, a traction device and the like. Among them, the suspension device has no traction power, and basically only plays the role of balancing bearing capacity. It includes an upper suspension wheel 1 arranged on the top of the frame 19. The upper suspension wheel 1 suspends the sucker rod 3 and the counterweight 18 respectively on both sides of the upper suspension wheel 1 through the suspension steel wire rope 2. Oil, the counterweight 18 moves up and down inside the frame 19 along the guide rail 17. The last suspension wheel 1 that is arranged on frame 19 tops is a non-powered mechanism, only plays suspension and guiding effect, so its diameter can be done very big. The diameter of suspension wire rope 2 depends on the hanging weight of suspension device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com