Method for manufacturing insulated gate bipolar transistor (IGBT) device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of high cost, and achieve the effects of eliminating temperature limitations, high activation rate, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] IGBT devices can be divided into three types: PT type (punch through), NPT type (non-punchthrough), and field stop type (field stop).

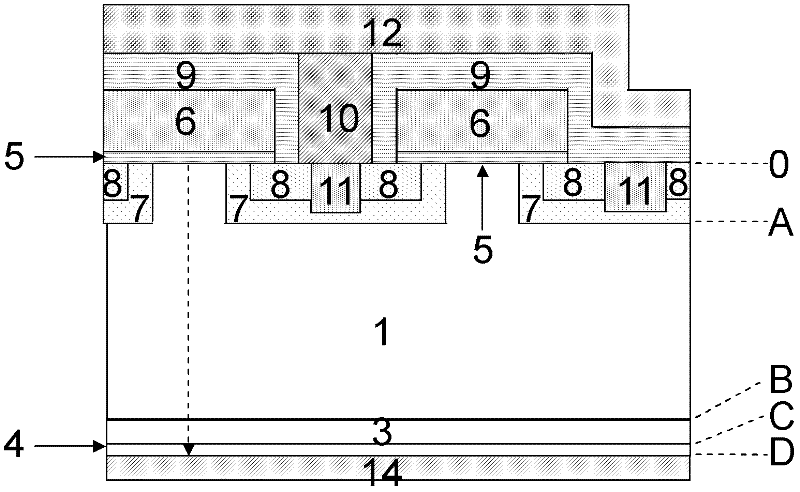

[0019] see figure 1 , which is a cross-sectional view of a field-stop IGBT device.

[0020] figure 1 The manufacturing method of the present invention of the shown field stop type IGBT device comprises the following steps:

[0021] initial state, see Figure 2a , the thickness of the silicon wafer 1 is, for example, 700 μm, which is doped with n-type impurities, and the doping concentration is, for example, 2.4×10 13 atoms / cm 3 (atoms per cubic centimeter), the resistivity corresponding to this n-type doped silicon wafer 1 is, for example, 180Ω·cm (ohm·cm).

[0022] Step 1, see Figure 2b A layer of dielectric 2, such as silicon dioxide, is deposited on the front side of the silicon wafer 1 to protect the front side of the silicon wafer 1, and then the silicon wafer 1 is thinned from the back side. The thickness of the deposited ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com