Method for improving reliability of under-gate technology high-K gate dielectric medium CMOS (complementary metal oxide semiconductor)

A gate-last process and gate dielectric technology are applied in the field of improving NMOS hot carrier effect and PMOS negative bias temperature instability effect to achieve the effect of improving reliability and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

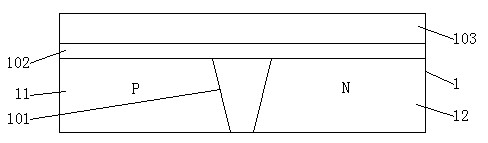

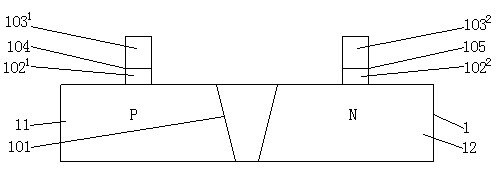

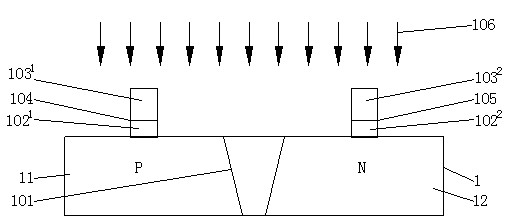

[0023] see Figure 1a As shown in -g, a method for improving the reliability of gate-last process high-K gate dielectric CMOS of the present invention, wherein, comprises the following steps:

[0024] A first dielectric layer 102 and a polysilicon layer 103 are sequentially deposited on the substrate 1, wherein the substrate 1 is provided with an isolation groove 101, and its two sides are respectively a P-type substrate 11 and an N-type substrate 12; using photolithography and Etching process, etching polysilicon layer 102 and first dielectric layer 103 to form NMOS semiconductor device sample gate 104 and PMOS semiconductor device sample gate 105, wherein, NMOS semiconductor device sample gate 104 is formed by first dielectric layer 102 1 and polysilicon layer 103 1 Composition, PMOS semiconductor device sample gate 105 is made of the first dielectric layer 102 2 and polysilicon layer 103 2 Composition: fluorine ions are implanted in the drain source region 114 by ion impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com