Excitation structure and alternating-current and direct-current excitation control method for frequency-variable alternating-current starting power generation system

A DC excitation, starting and generating technology, applied in the direction of controlling generators through magnetic field changes, can solve problems such as failure to start, problems with starting, changes in the excitation current of the main generator, and achieve the effect of meeting torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

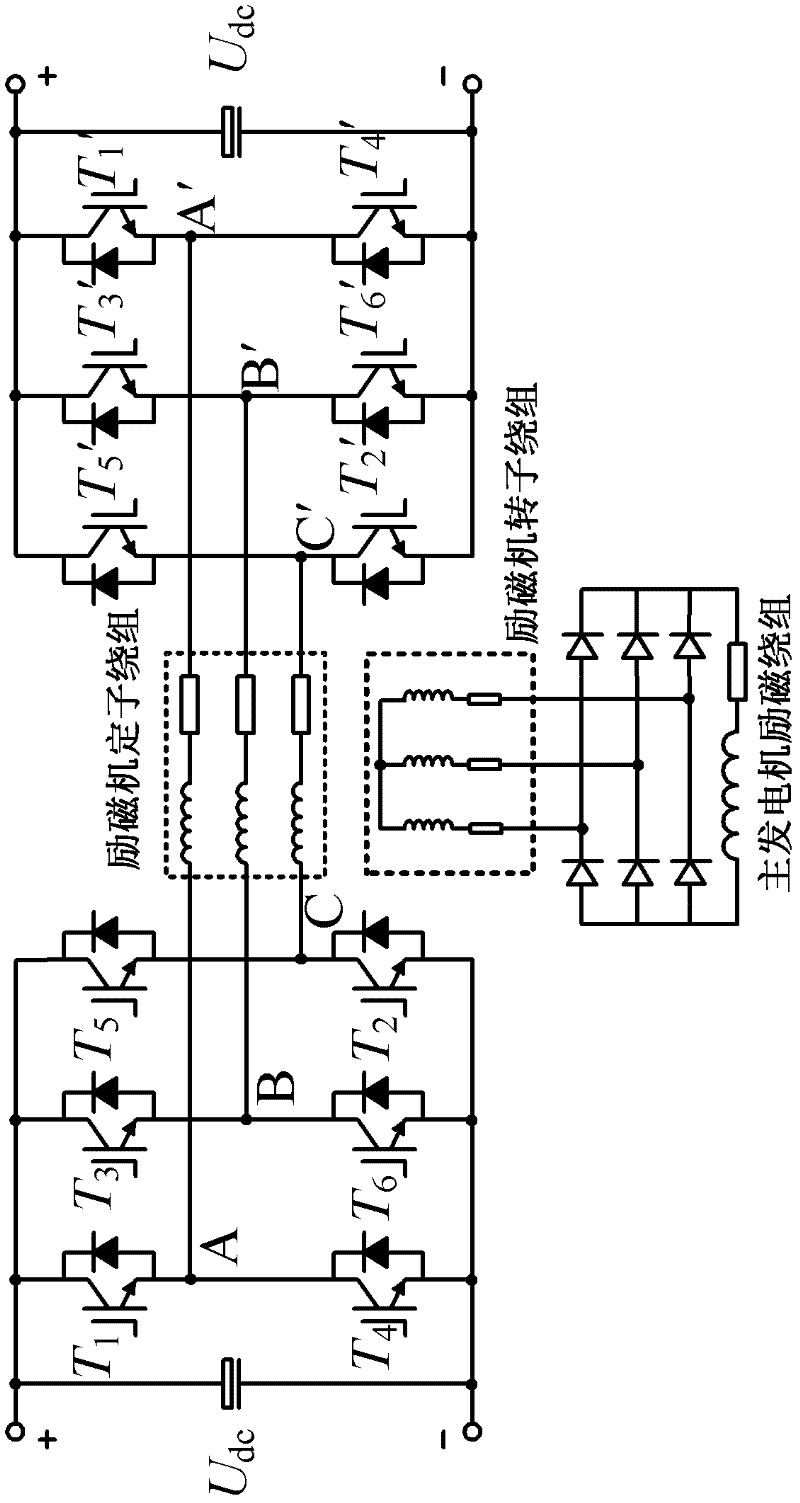

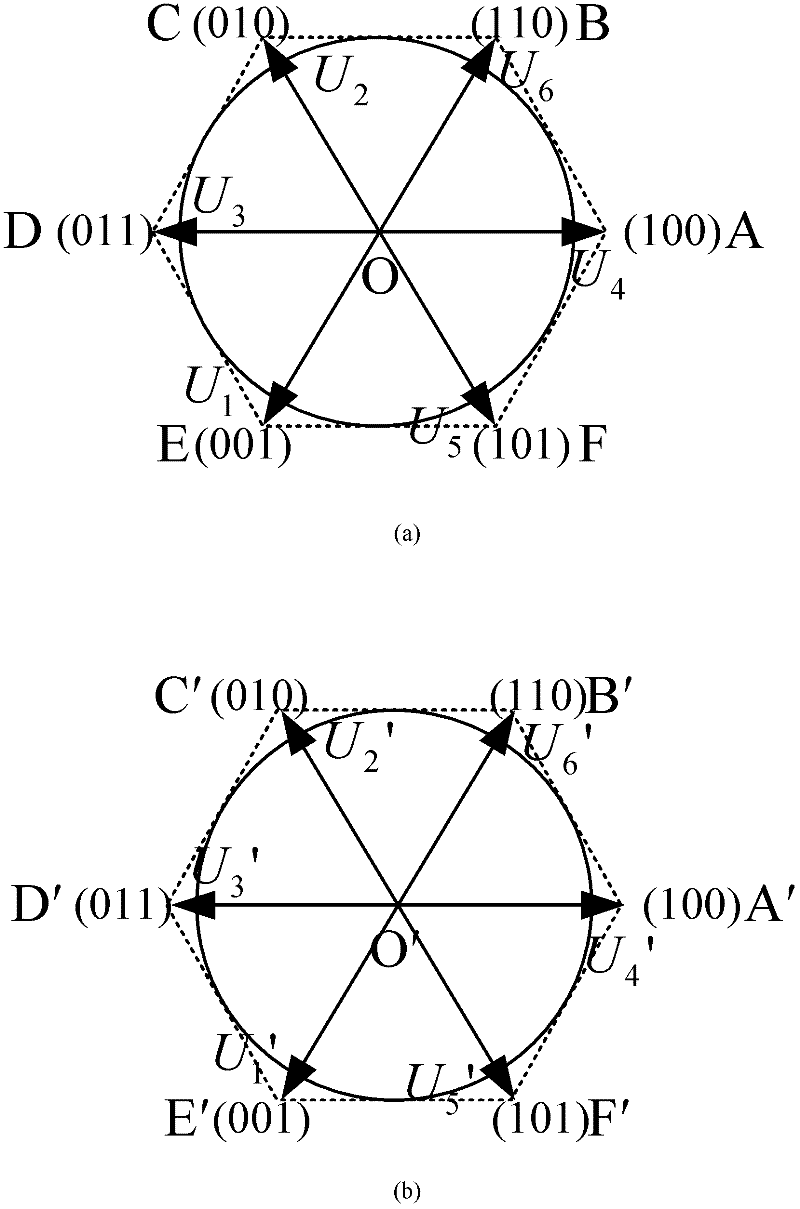

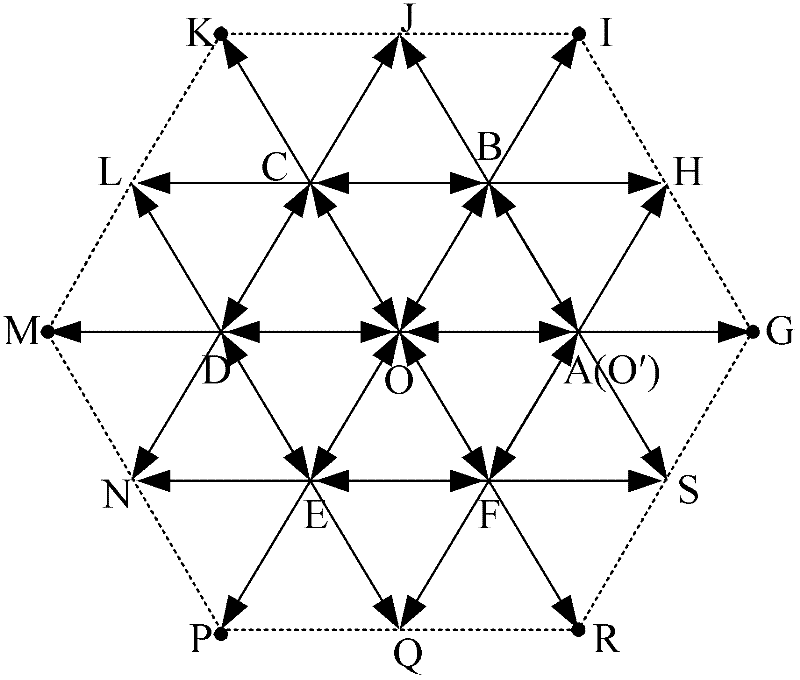

[0020] The structure of the three-stage synchronous motor AC and DC excitation control converter is as follows: figure 1 shown. The two ends of the stator three-phase winding of the exciter are respectively connected to a set of three-phase power converters, and the DC side of the two sets of converters are both connected to the excitation power supply U dc . In the initial stage of starting, from stationary to low-speed stages, two sets of power converters adopt the improved SVPWM control strategy to provide alternating current for the stator three-phase windings; in the medium-high speed and power generation operation stages, through the direct control of the excitation winding current of each phase of the stator, etc. The DC excitation winding is effectively formed to realize the voltage regulation control of the field-weakening speed-up and the power generation operation stage.

[0021] In the present invention, two sets of power converters can be controlled by SVPWM res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com