Vacuum automatic film pasting system

A film-attaching and automatic technology, applied in the direction of packaging, etc., can solve problems such as failure to meet product quality requirements, lens or shell film contamination, low work efficiency, etc., achieve high-precision vacuum automatic film-attachment, avoid air bubbles in the film, and improve The effect of lamination speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

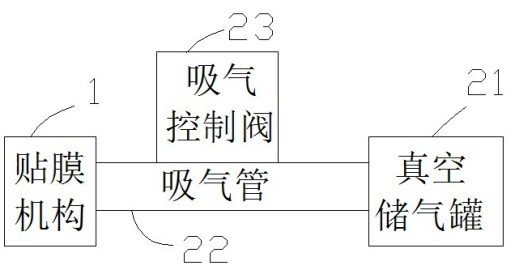

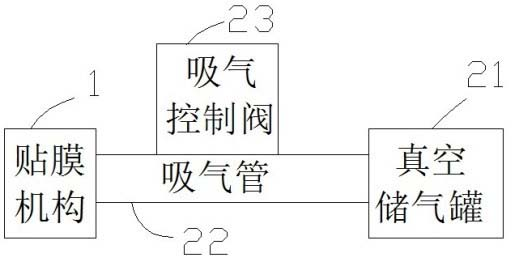

[0020] Such as figure 1 As shown, a vacuum automatic film sticking system includes a film sticking mechanism 1 and an air suction mechanism. The film pasting mechanism 1 includes upper and lower cover plates that are movably connected on one side. The upper cover plate is provided with an upper cover air cavity, and the lower cover plate is provided with a detachable workpiece carrier plate. The workpiece carrier plate is provided with four workpiece placement grooves. The bottom surface of the board is provided with the upper cover film adsorption blocks corresponding to the workpiece placement slots on the workpiece carrier plate one by one, that is, there are four upper cover film adsorption blocks on the bottom surface of the upper cover plate, and the distance between each upper cover film adsorption block is 2cm , each upper cover film adsorption block is provided with 25 air holes connected with the upper cover air cavity, the 25 air holes are divided into 5 rows and 5...

Embodiment 2

[0024] Such as figure 1As shown, a vacuum automatic film sticking system includes a film sticking mechanism 1 and an air suction mechanism. The film sticking mechanism 1 includes upper and lower cover plates that are movably connected on one side. The upper cover plate is provided with an upper cover air cavity, the lower cover plate is provided with a lower cover air cavity, and the lower cover is provided with a detachable workpiece carrier plate. There are three workpiece placement grooves, and the workpiece placement grooves on the workpiece carrier plate are connected up and down. The bottom surface of the upper cover and the upper surface of the lower cover are respectively provided with an upper cover film-adhesive adsorption block and a lower cover film-adhesive adsorption block corresponding to the workpiece placement grooves on the workpiece carrier plate, that is, the bottom surface of the upper cover plate and the upper surface of the lower cover plate. There are ...

Embodiment 3

[0029] The vacuum automatic film-attaching system of this embodiment is similar in structure to the vacuum automatic film-attaching system of Embodiment 2, the difference being:

[0030] In this embodiment, the workpiece carrier is provided with five workpiece placement grooves, and the workpiece placement grooves on the workpiece carrier are vertically connected, and the bottom surface of the upper cover and the upper surface of the lower cover are respectively provided with an upper cover film adsorption block and a Five lower cover film suction blocks. The distance between each upper cover film adsorption block and each lower cover film adsorption block is 5cm, each upper cover film adsorption block is provided with 80 air holes connected with the air cavity of the upper cover, each lower cover film adsorption block is set There are 80 air holes communicating with the air cavity of the lower cover. The 80 air holes on the film-adhesive block of the upper and lower covers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com