Flame-retardant blocking agent for substation as well as preparation method and use method thereof

A technology of substation and plugging agent, applied in the field of refractory materials, can solve the problems of high fluidity requirements of plugging materials, impermeable gaps, poor leveling, etc., achieve excellent plugging effect, overcome plugging The effect of dead angle, good performance and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of the flame retardant sealing agent that is used for substation of the present invention, comprises the steps:

[0033] Preparation of component A: take vinyl silicone resin, activated aluminum hydroxide and melamine according to the formula, put them into a vacuum kneader, and mix them under vacuum at 110-130°C to obtain the base material, which is ready to use after cooling; 100 parts of base material, add catalyst according to the formula, and stir evenly with a variable speed mixer to obtain component A;

[0034] Preparation of component B: Take vinyl silicone resin, hydrogen-containing silicone resin, inhibitor and tackifier from the formula, and slowly stir and mix with a variable speed mixer to obtain component B.

[0035] During the preparation of component A, the vacuum mixing time is 3.8-4.2h; the stirring speed is 1200-1700rpm, and the stirring time is 15-25min; during the preparation of component B, the slow stirring speed is 10...

Embodiment 1

[0038] A flame retardant plugging agent for substations of the present invention is composed of components A and B in a mass ratio of 5:1, and components A and B are formulated according to the following weight calculations:

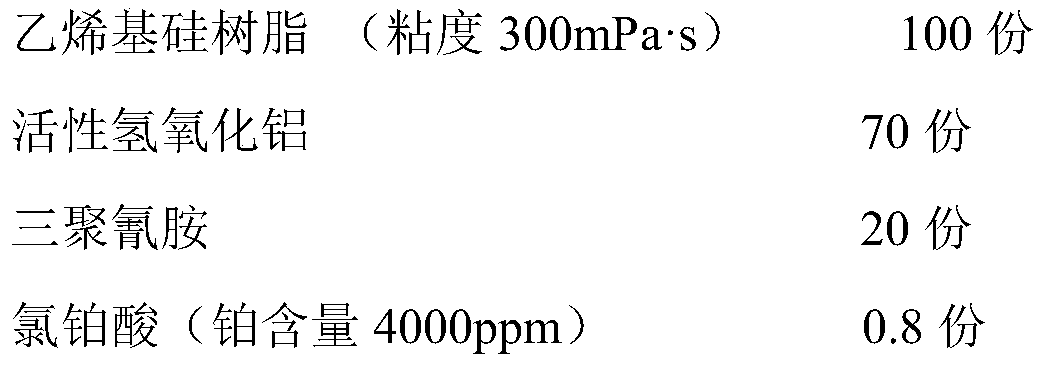

[0039] A component:

[0040]

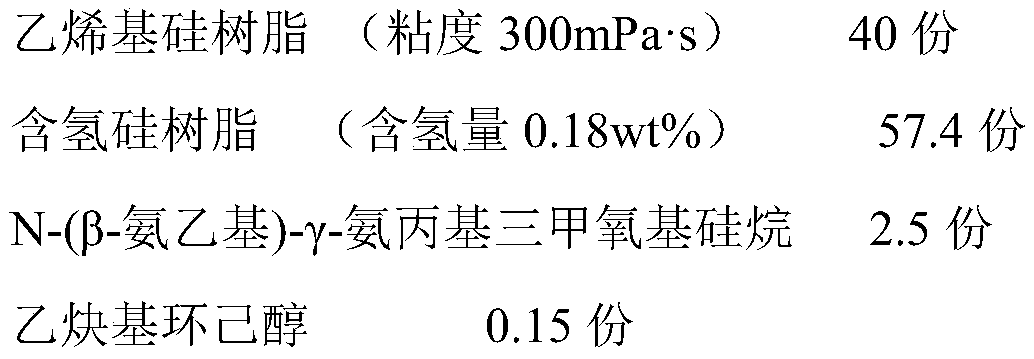

[0041] B component:

[0042]

[0043] A preparation method for a flame retardant sealing agent for a substation of the present embodiment, comprising the steps of:

[0044] Preparation of component A: add the vinyl silicone resin, activated aluminum hydroxide and melamine in parts by mass into a vacuum kneader, mix in a vacuum at 110-130°C for 4 hours, cool down and set aside; take 190 parts of the base material , 0.8 parts of chloroplatinic acid (platinum content 4000ppm), stirred for 20min under the condition of variable speed mixer 1500rpm to obtain A component;

[0045] Preparation of component B: slowly stir the vinyl silicone resin, hydrogen-containing silicone resin, ethynyl cyclohexanol and N-(β-aminoethyl)-...

Embodiment 2

[0047] A flame retardant plugging agent for substations of the present invention is composed of components A and B in a mass ratio of 5:1, and components A and B are formulated according to the following weight calculations:

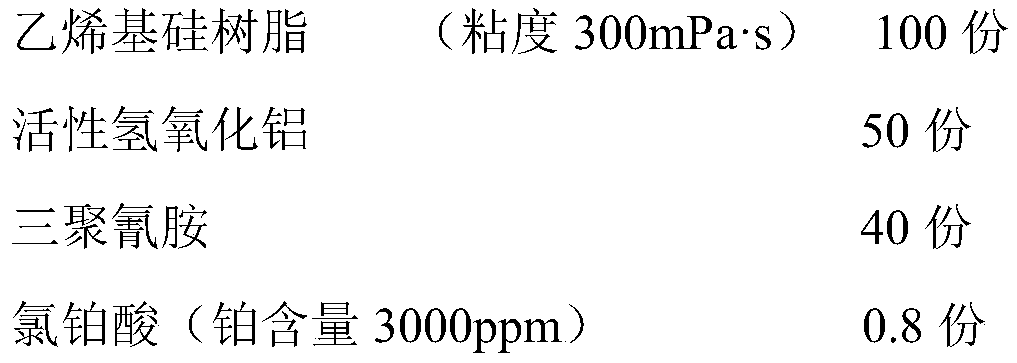

[0048] A component:

[0049]

[0050] B component: same as embodiment 1

[0051] A preparation method of a flame retardant plugging agent used in a substation in this embodiment differs from the preparation method in Example 1 only in that the ratio of raw materials is different in the preparation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com