Thermoelectric generator using superconducting fluid for heat transfer

A technology of heat transfer temperature difference and thermoelectric power generation sheet, which is applied in the directions of generators/motors, electrical components, etc., can solve the problems of high cost, low thermal conductivity, and slow heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

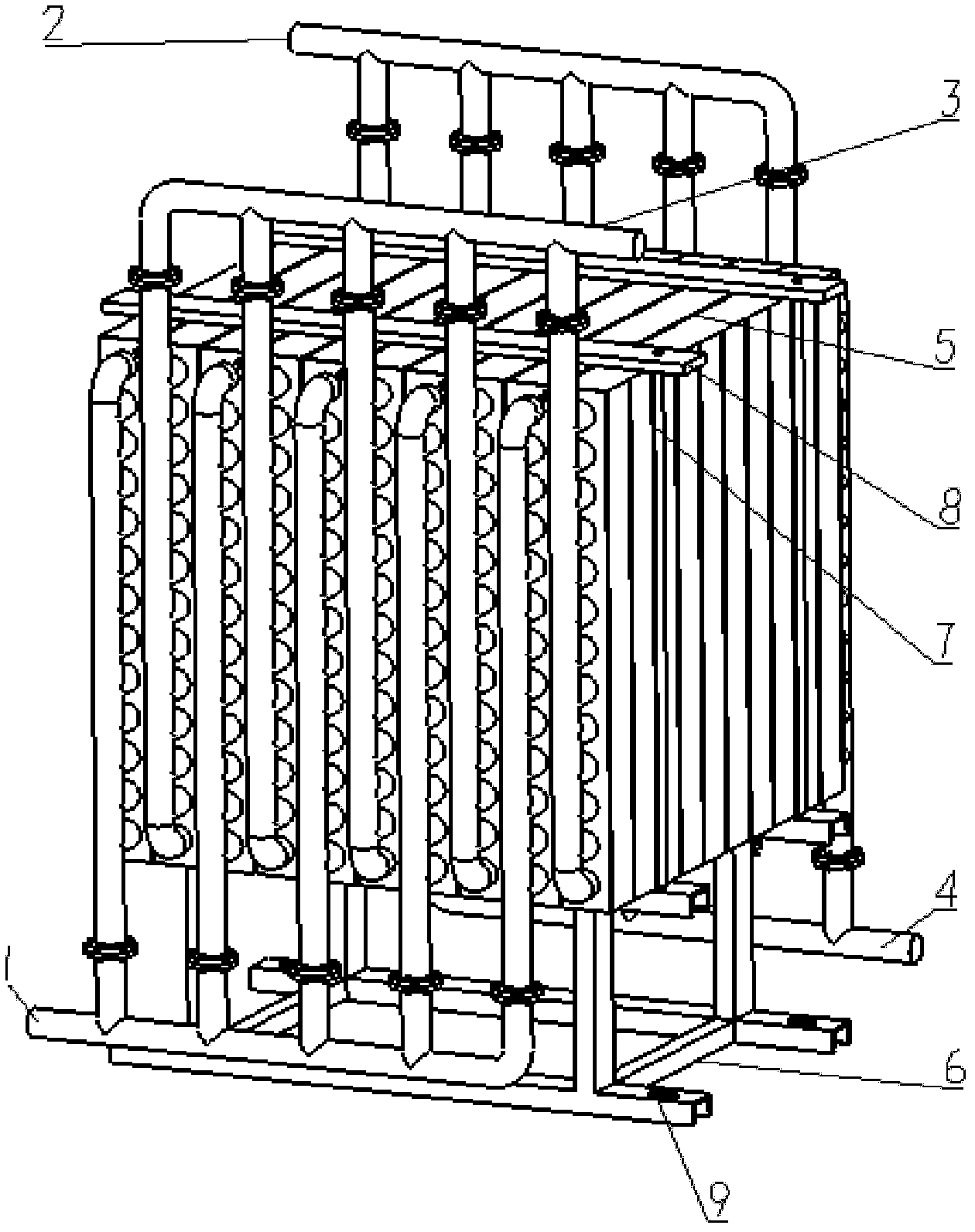

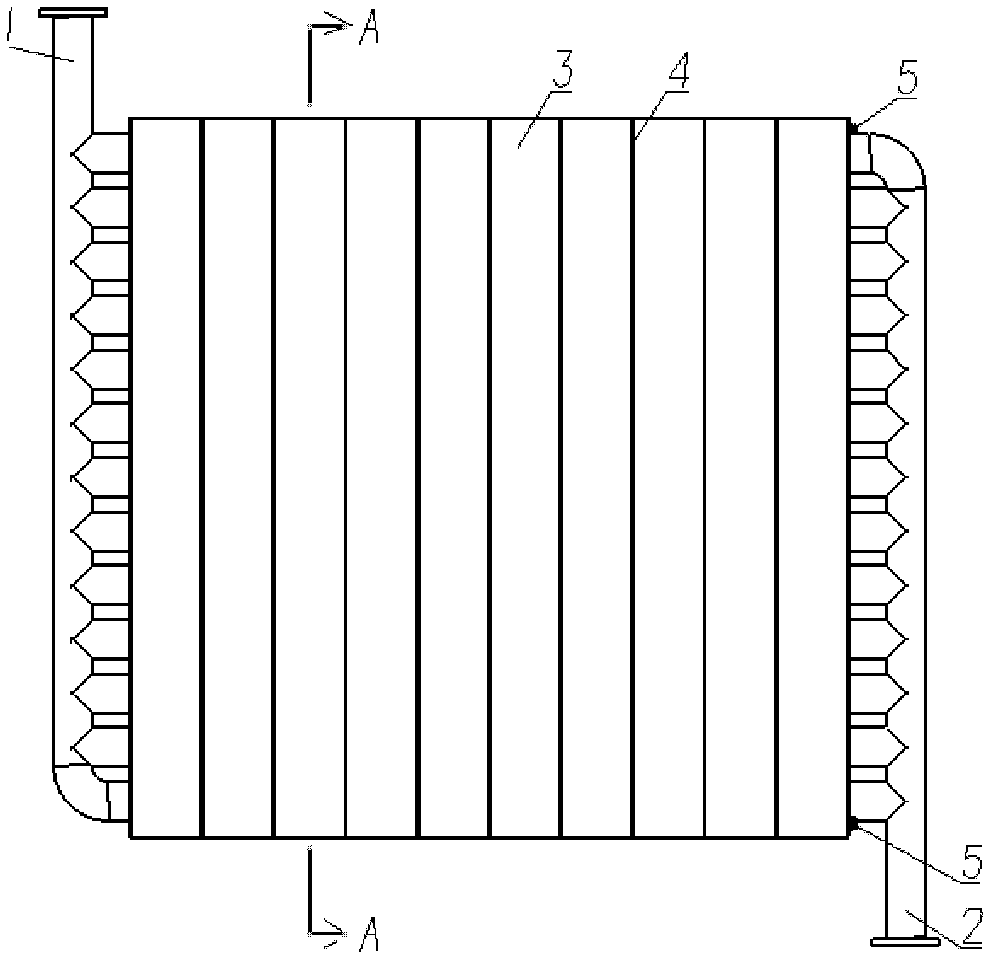

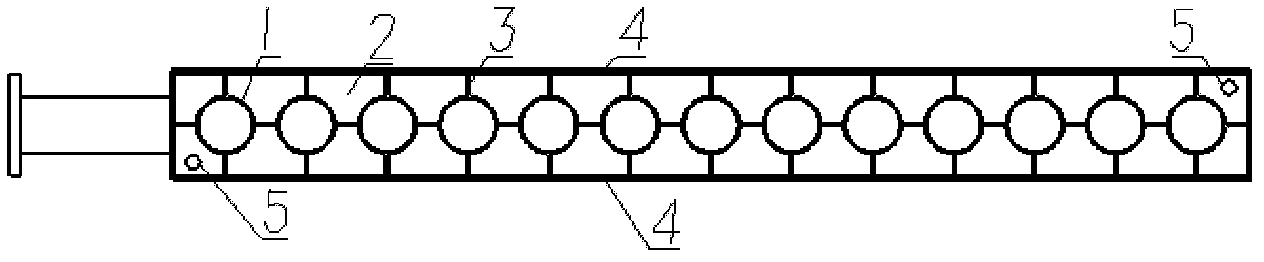

[0026] Attached below figure 1 , 2 5. The present invention is further described in detail through specific embodiments:

[0027] will attach figure 2 The plate heat exchanger module is filled with superconducting liquid and sealed. According to the specific situation, it can be filled in vacuum or at normal pressure. According to the temperature difference between the hot fluid and the cold fluid, the hot fluid heat exchanger module and the cold fluid heat exchanger In the module, superconducting liquids with different boiling points can be selected, and then press the attached Figure 5 The thermal fluid heat exchanger module, the thermoelectric generation sheet group, and the cold fluid heat exchanger module are assembled alternately in sequence. One side of the thermoelectric generation sheet group is in close contact with the high-temperature end surface of the thermal fluid heat exchanger module, and the other side is in contact with the cold fluid heat exchanger modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com