PCB (Printed Circuit Board) manufacturing method

A technology for a PCB board and a manufacturing method, which is applied in the field of PCB board manufacturing using dry green oil plug holes, can solve the problems of redness at the edge of the hole and the plug hole is not full, achieves smooth surface, full plug hole, and solves the problem of poor plug hole Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

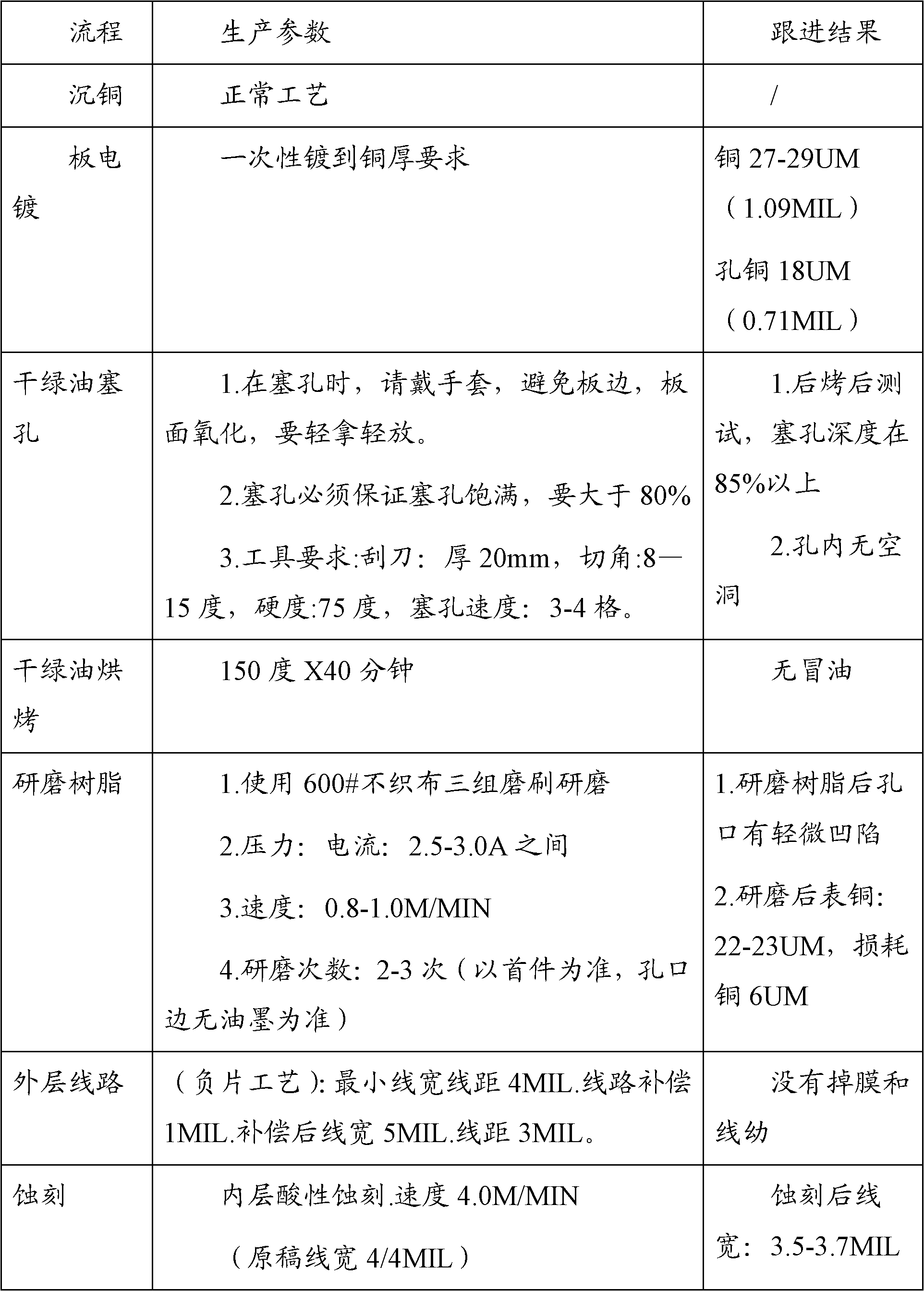

[0032] The invention discloses a method for manufacturing a PCB board, which includes the steps of copper immersion and board electroplating, and after the board electroplating step, the following steps are further included:

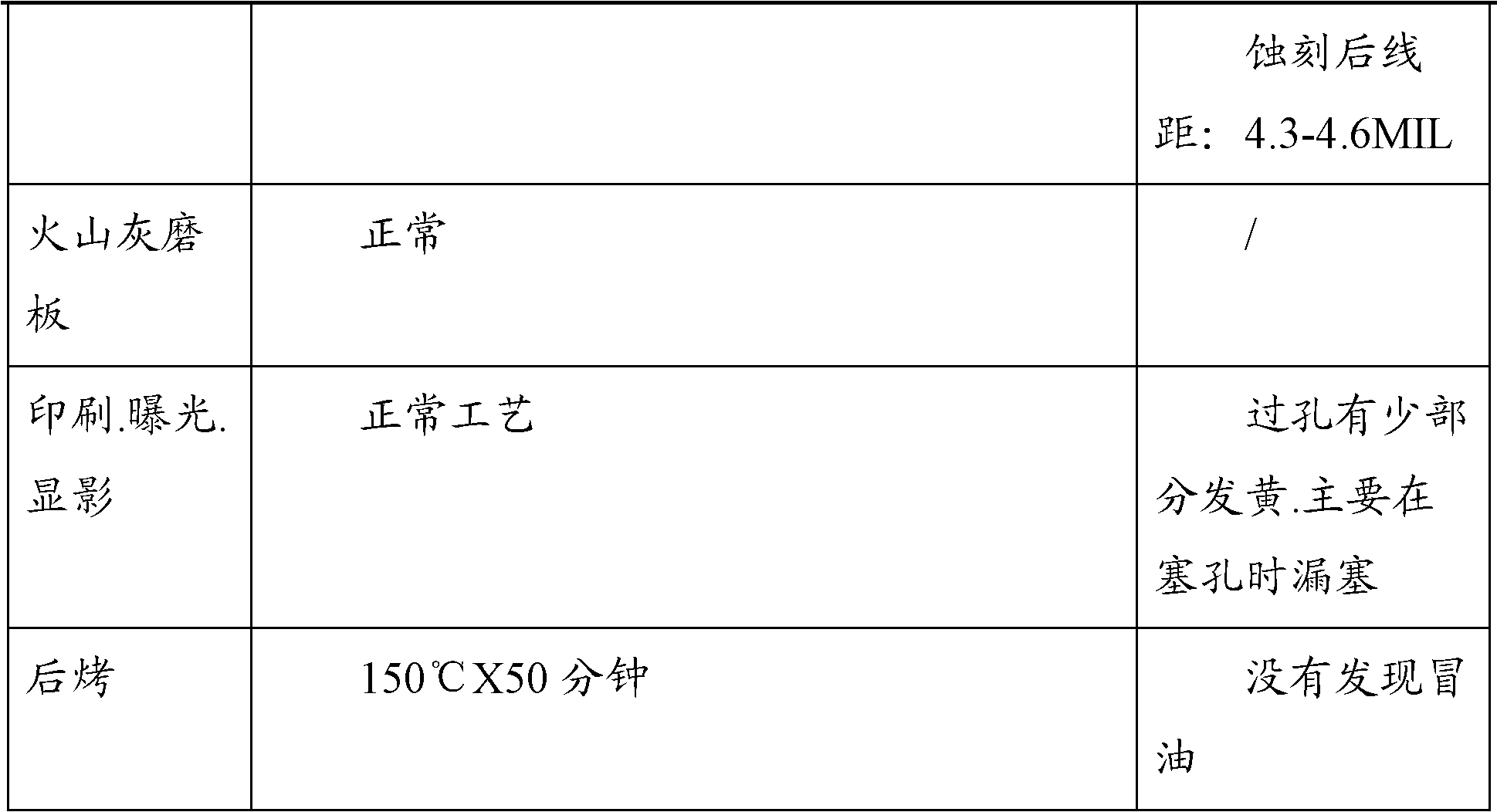

[0033] Step1: Grind the board, smooth and clean the PCB surface with a brush;

[0034] Step2: Plug the dry green oil, and use the printing machine to stuff the dry green oil into the hole of the PCB board. The area ratio of the dry green oil covered area to the hole area is required to be greater than 80%;

[0035] Step3: Post-bake, bake the PCB board at 150±5°C for 40-60 minutes; wherein, the baking temperature is preferably 150°C, and the baking time is preferably 50 minutes;

[0036] Step4: Grinding, use a non-woven brush wheel to grind the dry green oil protruding from the PCB surface, the grinding speed is 0.8-1.0 meters per minute, and the number of grinding is 2-3 times;

[0037] Step5: Outer circuit production, using negative film technology to make outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com