Rectification tower of 1,4-butanediol raffinate recovery system

A recovery system and rectification tower technology, applied in the field of rectification towers, can solve the problems of enterprise economic loss, inability to meet high-purity requirements, waste of resources, etc., and achieve the effect of improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

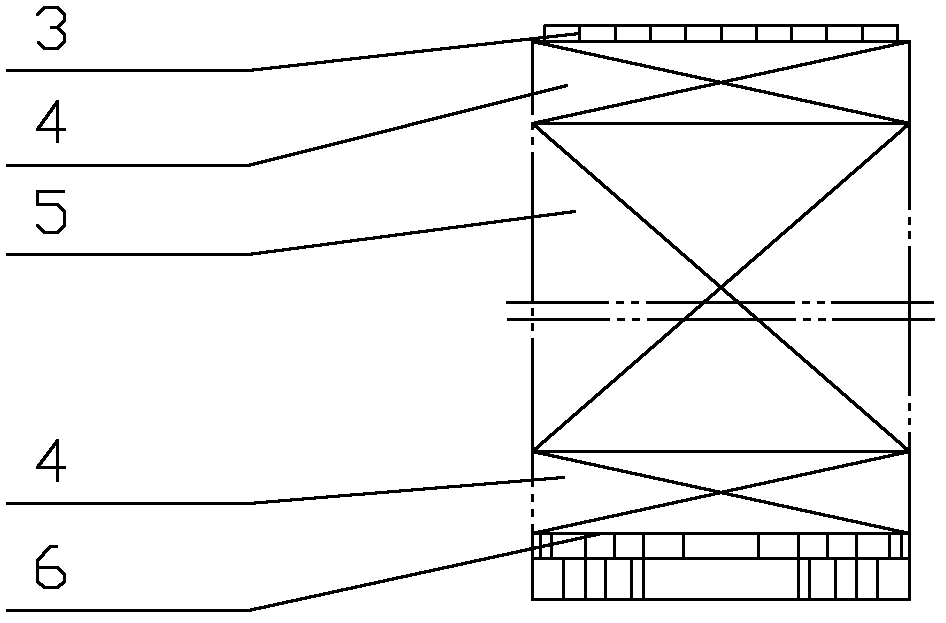

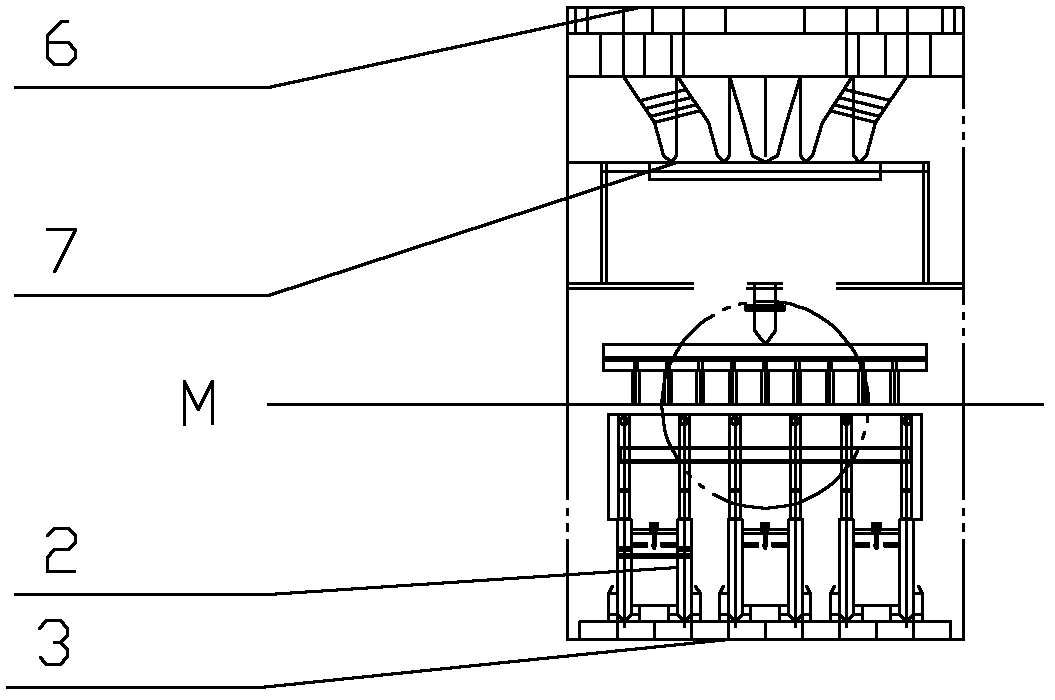

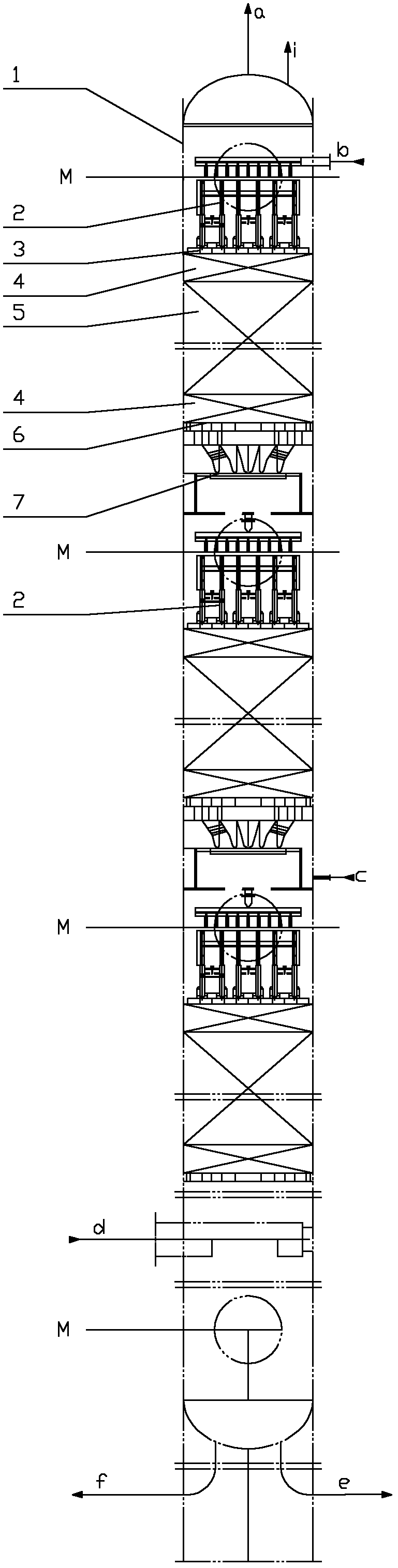

[0016] Such as image 3 As shown, the rectification column of the 1,4-butanediol raffinate recovery system includes tower body 1, 3-stage packing section, tower top gas outlet a, reflux liquid inlet b (connected to the rectification tower reflux tank, the tower Part of the condensate cooled by the top condenser is returned to the tower as the top reflux of the rectification tower), the feed port c, and the reboiler return port d (connected to the reboiler of the rectification tower kettle, and the reboiler passes through Heating the material in the bottom of the tower to partially vaporize it and become rising steam, which provides heat and mass transfer for the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com